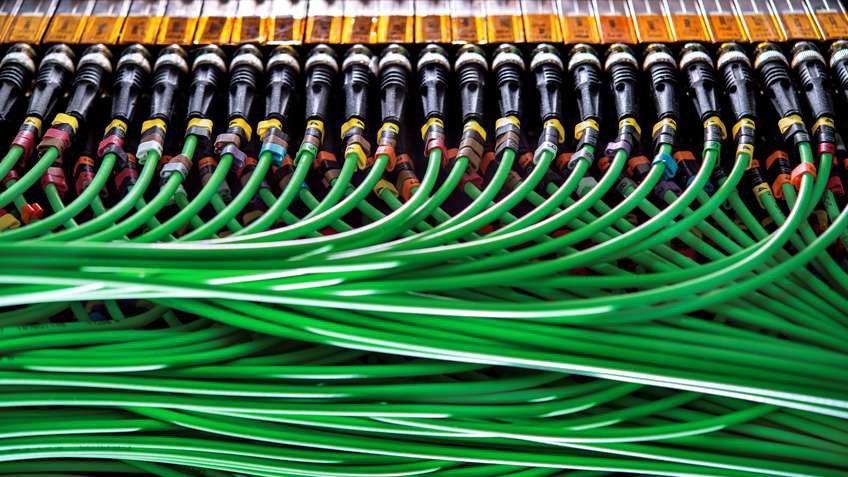

Foundational to The Connected Enterprise® are the “connections”, that is, the data cable wiring, or the physical network infrastructure. More than obvious, right?

Yet why do we oftentimes see that it is handled and managed separately from the balance of the project as to be out-of-scope? Or bolted on at the end as after-thought. Perhaps some consider it to be either unimportant, simplistic, or menial.

It is these assumptions that can doom projects causing them to go “sideways.” It is much more than “pulling cable.” Though not obvious to some, there is considerable science, skill and know-how behind a successful installation. There are extensive standards to adhere to when designing and installing a data cable network – and the task is more complex for heavy industry and process applications.

In regards to its importance and relevance, consider these two things:

- Some 80% of network slowdowns and outages (think unplanned, highly visible and costly production stoppages) are attributable to issues with the cable install.

- The life expectancy of the physical network, the cable plant, is 20+ years, during which it is to perform admirably and reliably throughout while supporting several refresh cycles of hardware and software.

Logical and Physical Networks

This is enough, I think, to encourage inclusion of the physical network into the project scope right along with the logical network. Logical and physical? What? Think of it in terms of a marriage.

First understand that the logical network topology defines the data traffic switching, routing and segmentation. The logical network must be designed to expressly support the control and data system architecture. They both must be done in unison.

They must be united. In like manner, the physical network infrastructure (the data cable, connections and enclosures) must be designed and installed to align with and support the logical network for the environment and applications at hand. The logical and physical networks are explicitly coupled and co-dependent and therefore must also be done in unison. From a design and deploy perspective, severing the two invites plenty of risk.

The Pain of a Disconnect

I’m guessing that some of you reading this may have experienced the pain and added expense during a startup and commissioning as the result of missteps and gaps associated with the network – when the cable install is not aligned, nor best-practices followed.

To demonstrate the point, two recent projects in the U.S. come to mind: one at a large midstream oil and gas facility and the other at a wood products mill.

In both cases, the cable install was contracted out and managed separately. Problems ensued, and as a result, “white hats” from both Rockwell Automation and Panduit had to be pulled and dispatched for protracted rescue missions. Many deficiencies were found. In the end, the projects were saved, but not after serious delays and costs for remedies. These scenarios are avoidable.