Recommended For You

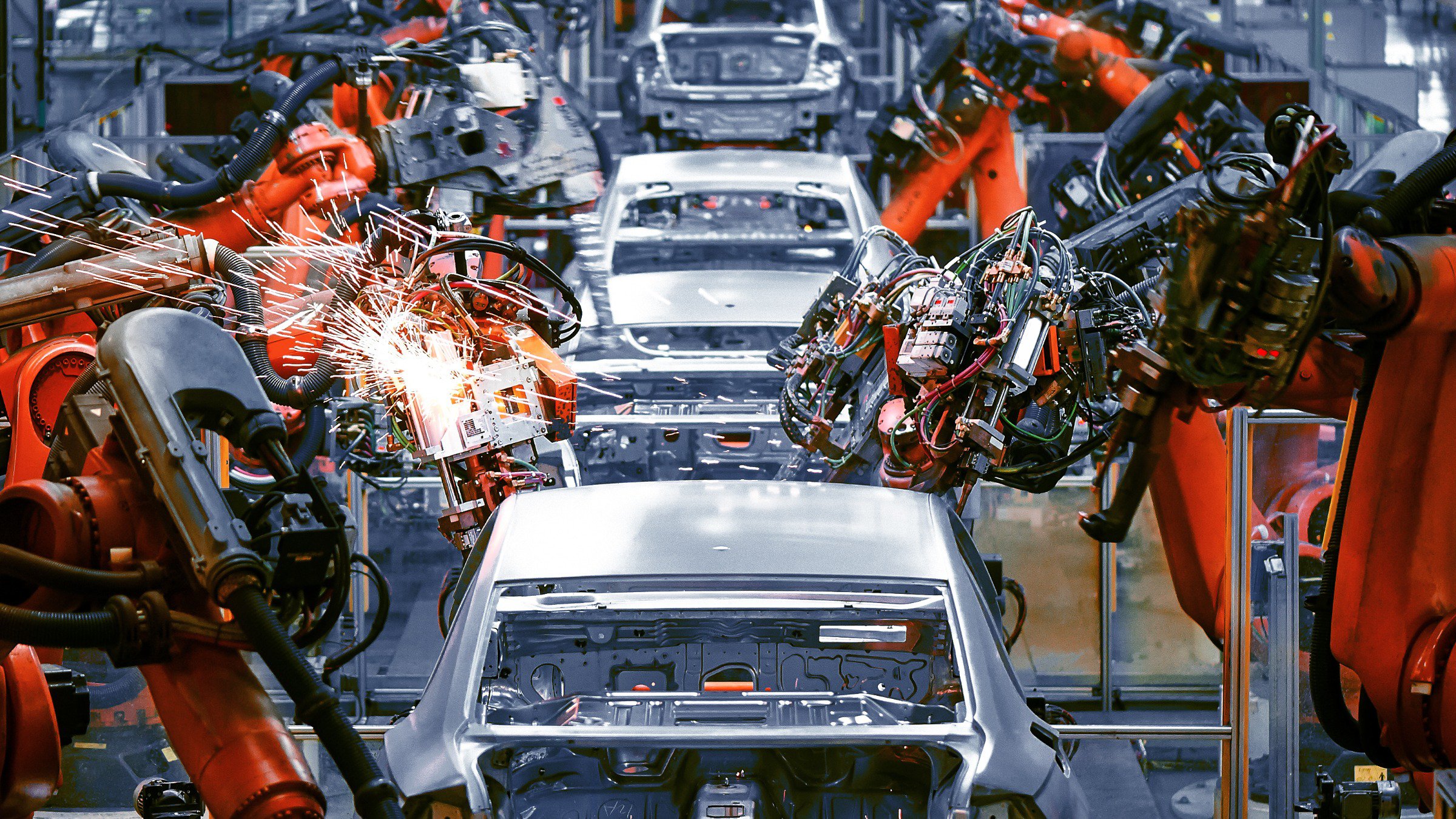

Not so long ago, the automotive supply chain was characterized by a diverse group of regional component suppliers.

But over the past decade, carmakers have accelerated their move toward global modular platforms – and have demanded the same from their suppliers.

In response, the largest automotive suppliers have transitioned to modular offerings encompassing everything from complete cockpit assemblies and seating systems to powertrains.

And through a banner number of mergers and acquisitions, they continue to expand their scope and align their geographic footprint with their customer base.

This new streamlined supply chain has enabled automakers to drive more efficiency across their operations – and reduce their overall capital expenditures.

Of course, this business model also promises new levels of profitability for the automotive supplier.

But it may also expose a need for higher levels of manufacturing intelligence on the plant floor to improve production flexibility and efficiency – and help mitigate risk.

A scalable, modern manufacturing execution system (MES) can help auto suppliers achieve the responsiveness they need to address these challenges head-on.

How? The key is an extraordinary level of information integration that extends from smart devices on the factory floor to enterprise resource planning (ERP) systems.

Suppliers can collect data from throughout their operations, contextualize and analyze it – and finally, act on it.

Let's take a closer look.

Manufacturing Flexibility & Efficiency

Automotive suppliers' fortunes have always reflected the industry at large. Once, the equation was a relatively simple one: Positive industry forecast = More component orders. Production was adjusted accordingly.

But as suppliers take on design and manufacturing responsibility for larger portions of the vehicle, they must rethink production strategies and respond to the market more like the automakers they serve.

That means focusing innovation on industry mandates like fuel-efficiency – and aligning production with changing consumer preferences and just-in-time supply chain requirements.

By implementing a Rockwell Software MES solution, suppliers can improve agility and responsiveness in many ways.

For example, the production order management application streamlines material coordination and key build parameters throughout the production process – and provides real-time inventory visibility to keep lines moving.

And when a new order is received, the application can immediately obtain the order information and build data from the business system – and convert it to detailed build sheets for faster response on the plant floor.

Risk Mitigation

With vehicle recalls reaching record levels in 2015, improving automotive quality management has taken on new urgency. As the industry shifts increasingly towards modular supply, automakers are requiring suppliers to share more responsibility for warranty and recall claims.

To improve quality management, the error proofing application can transform a bill of materials and procedures into enforceable work instructions. Should an error occur, hold and quarantine activities can help prevent the affected assembly from entering the supply chain.

If a supplier must respond to a recall or warranty issue, genealogy and track-and-trace capabilities can provide forward and backward traceability to identify quality issues – as well as real-time product location linked with critical production data to help limit the scope of recalls.

The Beauty of the System is Scalability

Keep in mind, these are just a few examples of how a Rockwell Software MES solution can help suppliers meet the demands of an increasingly complex manufacturing environment.

The real beauty of the system is its modularity and ease of use. The system is built on a common infrastructure that enables auto suppliers to cost-effectively implement the applications they need today. And easily extend the system as needs evolve.

Published May 9, 2016