“They needed help with how to leverage one drive that could perform testing with multiple encoder inputs,” Jack explains. “We worked with Rockwell Automation and Kendall Electric, a distributor we utilize, to help our controls engineering team come up with a solution.”

That solution features Rockwell Automation’s PowerFlex® 755 Drive, Compact GuardLogix® controller, and an ENC1 Encoder.

Increasing Efficiency while Exceeding Customer Expectations

“We used the PLC controller to generate the recipes for the parameters of each motor drive which is then interpreted through a barcode scan,” Jack says. “So, every time a specific motor was loaded into the test center, we were able to check speed, torque and linear profile.”

Eagle’s solution not only enabled its aerospace customer to meet mandatory test criteria, but also streamlined and optimized the testing system.

“Utilizing one common drive is a lot more efficient than multiple drives. So, we did have some power savings there,” Jack explains. “But ultimately, what impressed the customer was the robustness of the Rockwell Automation solution and our ability to minimize the number of solution components.”

Demonstrating the Benefits of Technology Advancements

While Jack describes this aerospace customer as an early adopter of new technology, he notes other customers, regardless of sector, require a bit more encouragement and understanding.

“I think customers sometimes default to what they know,” he says. “Our job as an integrator, along with Rockwell Automation as a provider, is to educate customers about the value proposition of investing in technology because the long-term results of applying newer technology far exceed performance of current equipment.”

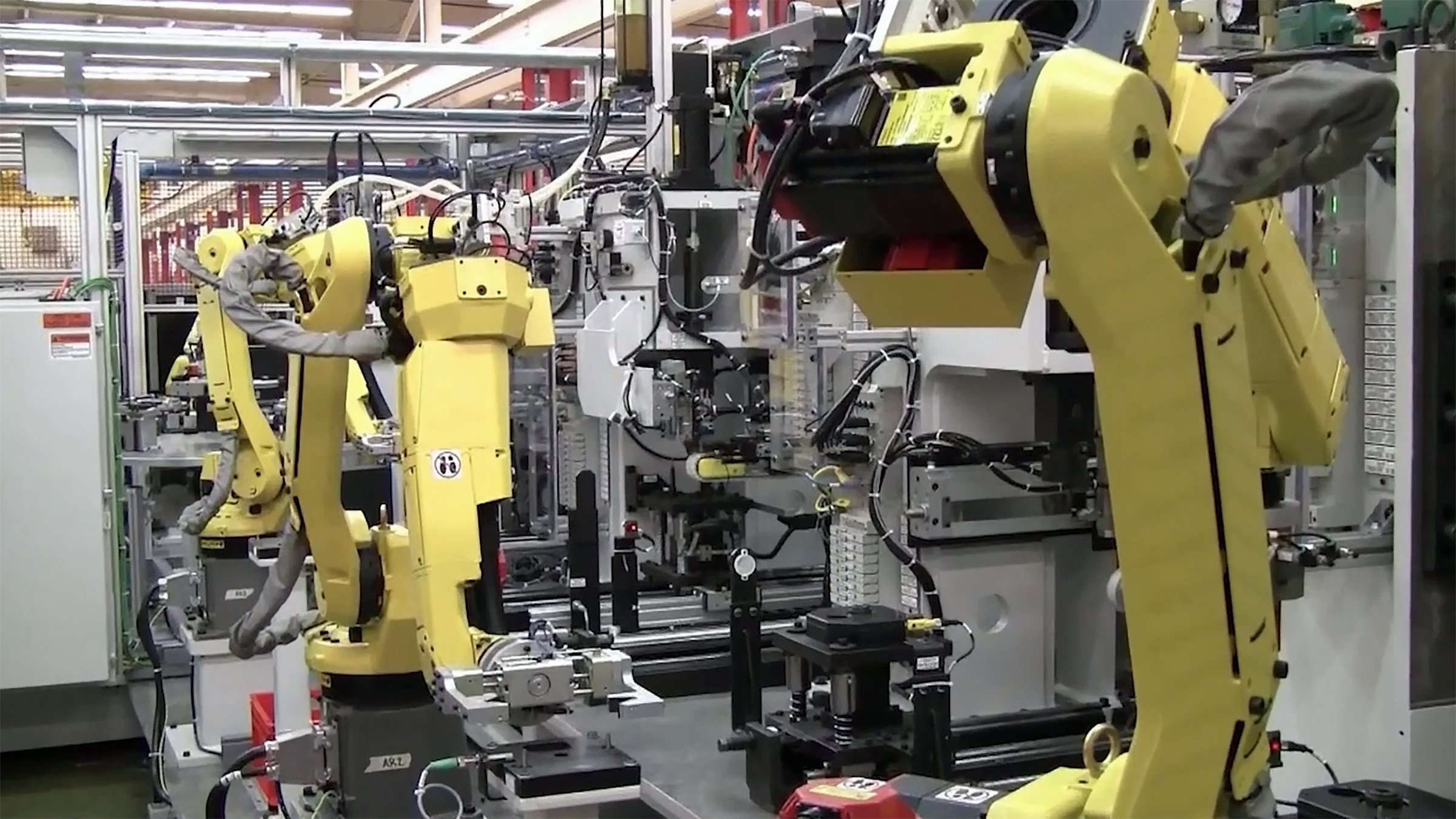

Such educational efforts include demonstrating new technologies. For example, Eagle has been on the cutting edge of advancements in the automotive market, including battery and motor production for electrical vehicles. That’s why Rockwell Automation asked Eagle to develop a prototype lithium-ion battery assembly and test system for its Electric Vehicle Innovation Center, in San Jose, California.

“It’s a fantastic demonstration of smart machine technologies now available across our broad portfolios, including robotics, artificial intelligence and augmented reality,” Jack says. “And when customers across the globe visit, they're very impressed with both Rockwell Automation and hopefully Eagle as well.”