FactoryTalk® Analytics™ VisionAI™ takes a no-code approach to vision inspection to improve quality, maximize yield and gain critical insight from real-time production data. Throughout the entire user workflow, from camera configuration and capturing images to training and deploying models, and even for analyzing quality performance, our machine learning and vision inspection solution is designed so that quality personnel and plant operators can view the information they need to achieve their quality performance targets.

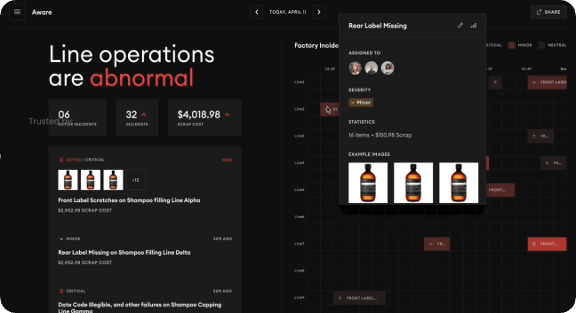

Identify and classify defects

FactoryTalk Analytics VisionAI finds defects, previously impossible to detect, driving insights and actions.

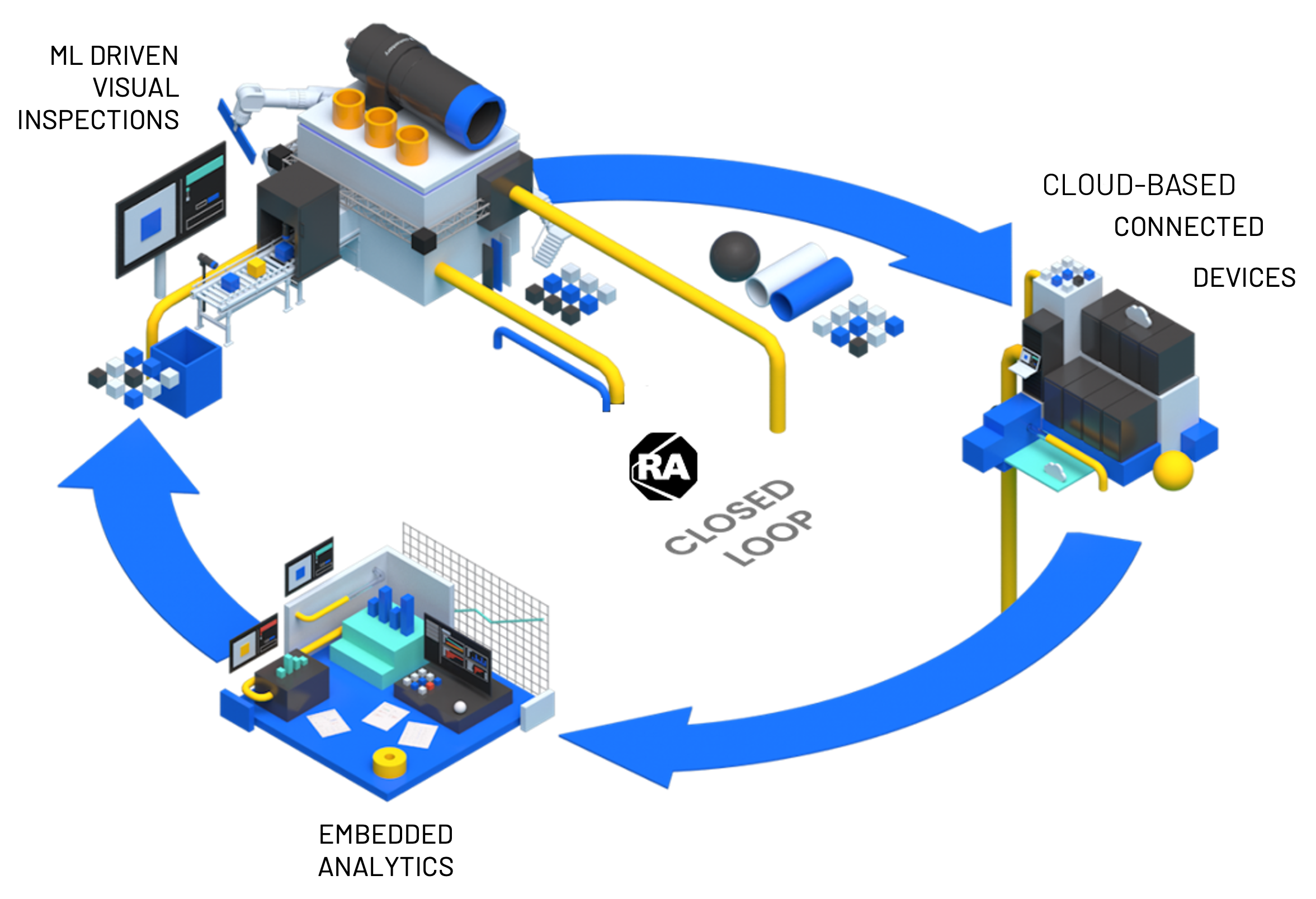

Built in the cloud for closed loop quality at the edge

Artificial intelligence (AI), machine learning and model management in the cloud to deliver unparalleled, advanced quality inspection

Simplify quality inspection

Rockwell Automation combines hardware, software and domain expertise to simplify quality inspection

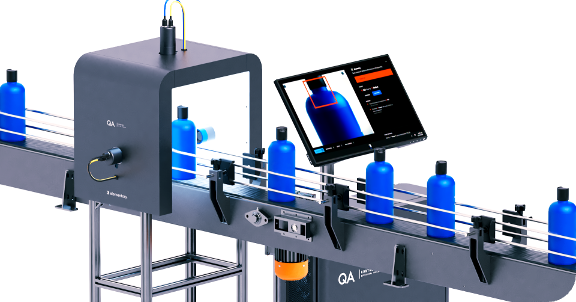

Hardware

Real-time inspections at manufacturing speeds with an integrated solution

Essential automation integration via standard industrial protocols

Scalable hardware using off-the-shelf components to fit any inspection application

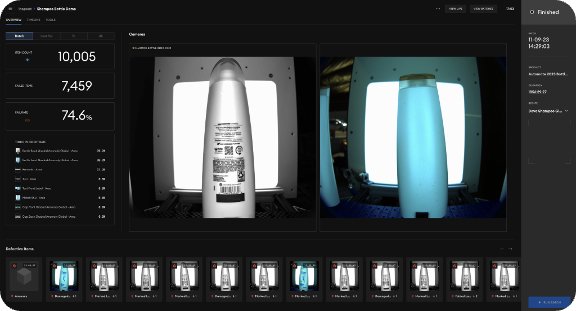

Software

Essential analytics stores all image data, exposes through APIs and AI-driven insights

Remote operations allows the production line to be updated from the cloud in real time

Machine learning model management means AI that scales efficiently

Domain Expertise

Integrations to allow alerting and management from anywhere

Enterprise manageability scale the ROI on your deployments

Cybersecurity is a core principle and FactoryTalk Analytics VisionAI is built on SOC 2 compliant technology

Fit for many manufacturing industries

Out-of-the-box analytics for discrete and hybrid industries

CPG

Automotive

Medical

Food & Beverage

Electronics

AI for machine vision systems

Our end-to-end FactoryTalk Analytics VisionAl workflow enables manufacturers to easily deploy machine learning models across their facilities. Model development relies on production experience and a clear understanding of what good and bad quality products look like, reducing the need for machine vision expertise to create or update models. Once models are deployed, the AI in VisionAI brings a more intuitive analysis of images, allowing for a human-like interpretation of the product during the inspection process.

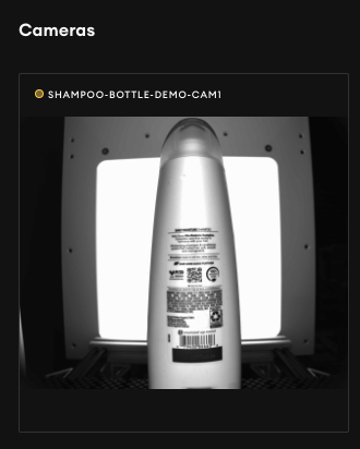

Capture

Inspect

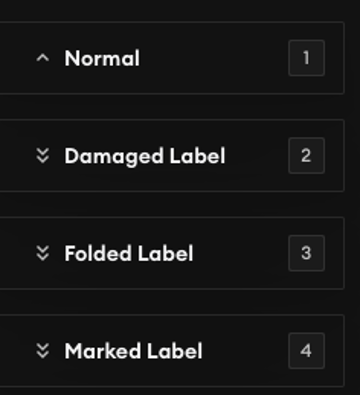

Label

Create - Labeling Gallery

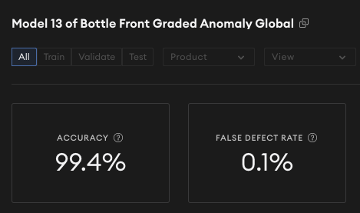

Train

Create - Training Management

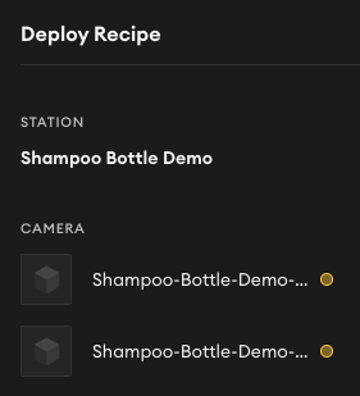

Deploy

Create - Recipe Management

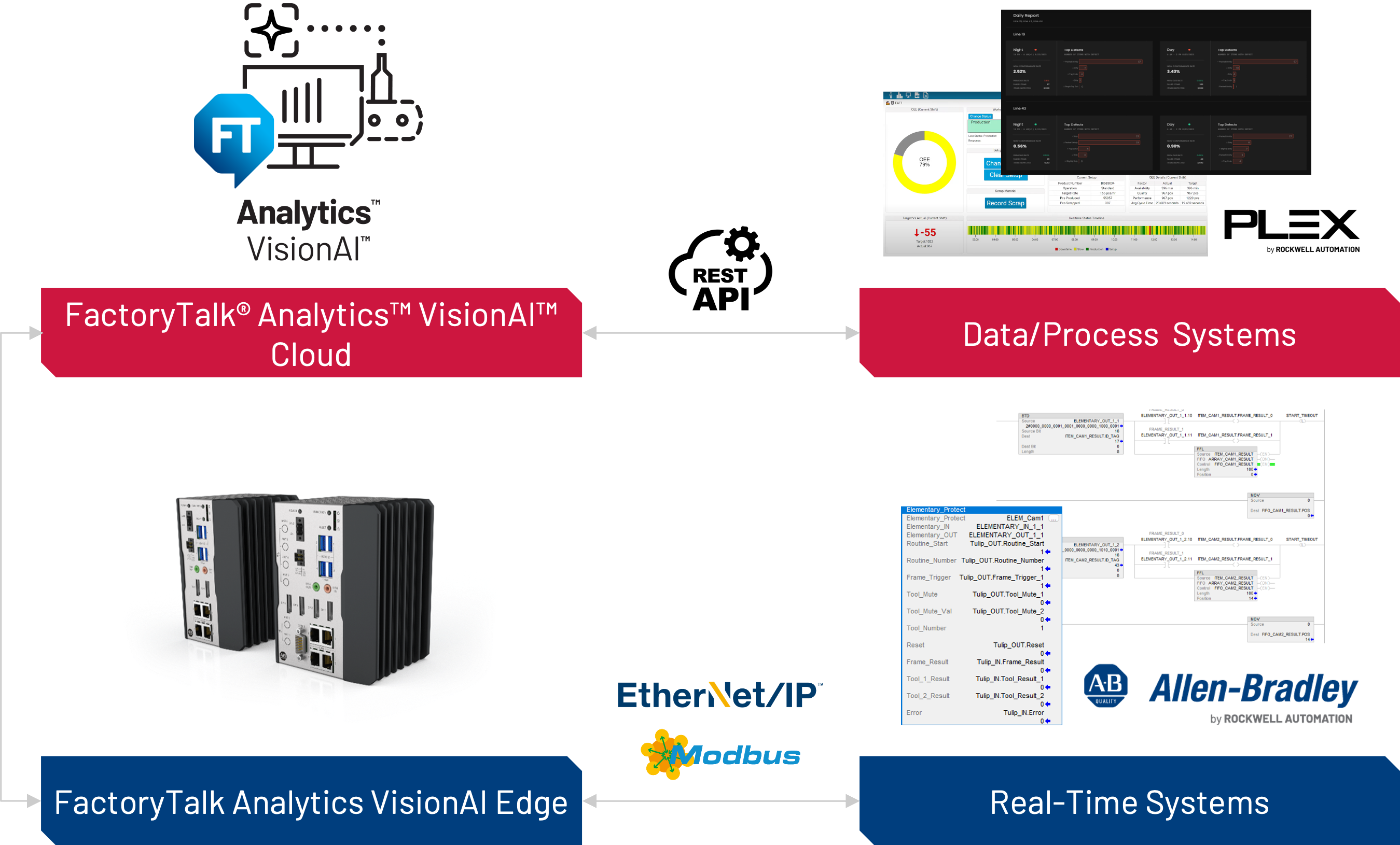

Integrations through the cloud and industrial protocols

Cloud Integrations

- Typically used for data analytics or process management applications

- Integrate via bidirectional Rest API

- Examples: BI tools, MES/QMS systems

Factory Floor Integrations

- Typically used for real-time command and control of systems on the factory floor

- Integrate via Ethernet/IP

- Examples: Rejection systems, conveyors, factory devices

Rockwell Automation Integration

Rockwell Automation provides an integrated solution, simplifying installation and shortening the time value

Cloud

- Simplified cloud access via FactoryTalk® Hub™

Hardware

- Architecture built on Allen-Bradley ASEM™ IPC and Logix PLCs

Control System

- Add-on Profile for premier Logix Integration

- FactoryTalk® Optix™ Object Library for visualization integration

The Rockwell Automation Difference

Scalable solution with intuitive, OT focused workflows that don’t depend on specialists

Data-driven quality decisions empowered by out-of-the-box advanced analytics

Smart vision that integrates with control to deliver value in closed-loop

Frictionless integrated vision, control and operations in one platform from one supplier