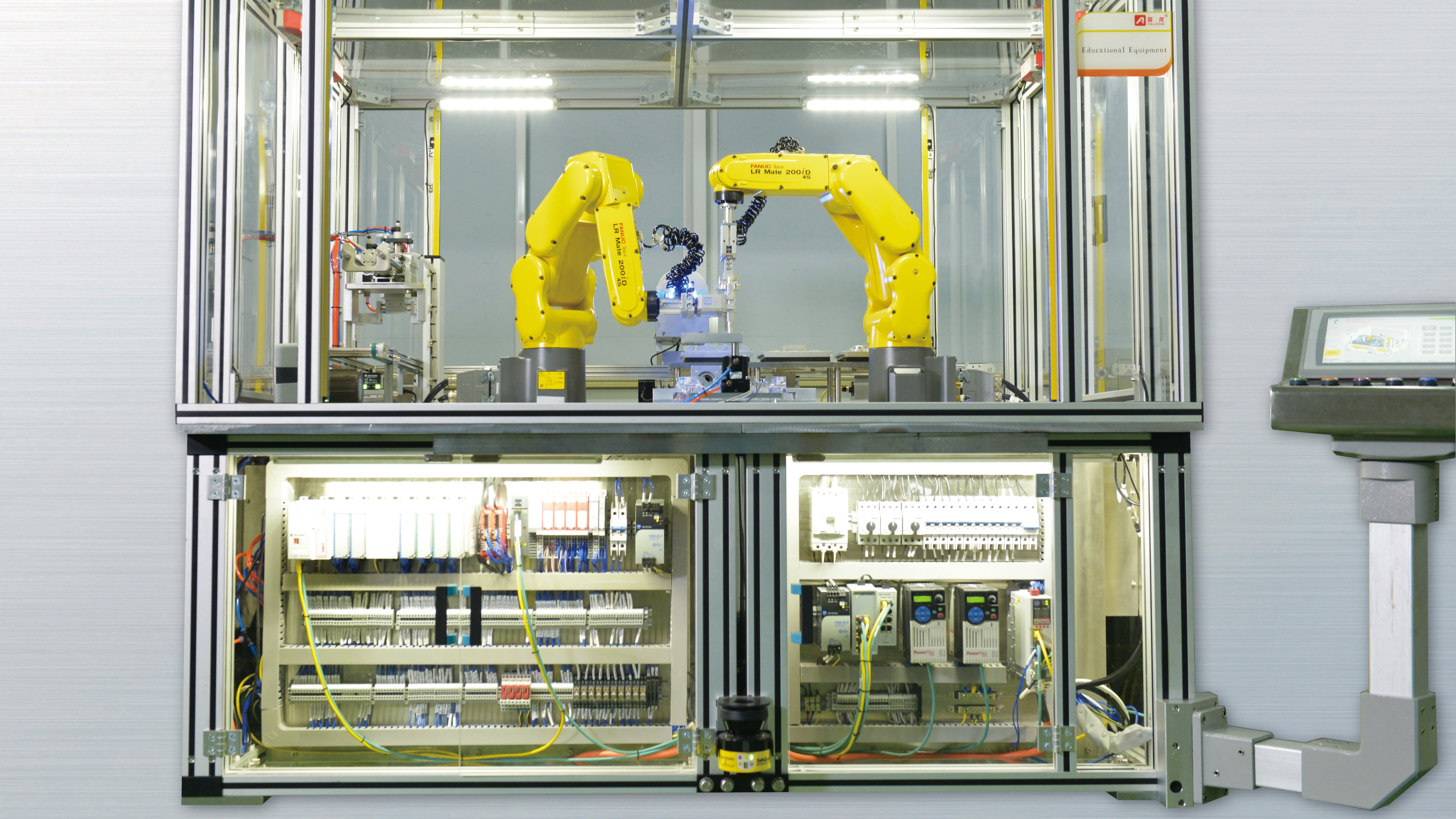

Smart machines like the YL1805B gearbox assembly machine deliver:

- Unprecedented access to real-time data that can be turned into actionable information. Granular data can be logged and analyzed to help employees make better decisions and ultimately optimize equipment and manufacturing processes; and improve operational efficiency, quality and output.

- Greater connectivity via an open, standard network architecture – such as EtherNet/IP – enabling real-time collaboration and data sharing upstream and downstream, and across the enterprise.

Smart Machine Delivers Real-Time Data

The YL1805B gearbox assembly machine demonstrates the capabilities a smart machine with an integrated safety system.

It utilizes FactoryTalk® View SE and PanelView™ Plus graphic terminals to display real-time status of the safety system, including E-stops, light curtain, scanner and door switches. The FactoryTalk® Metrics system collects and reports on machine performance, safety events and safety reason codes. It shows performance data including OEE with machine working time, number of assembled gear boxes a day/per hour, and quality. It also produces a downtime report with a summary of events (idle, faults and safety); and a daily safety occurrence report.

Smart Safety Tools Ease Compliance

Now, users have a single tool suite to help manage, document and confirm compliance throughout the entire safety development. The Safety Lifecycle Toolkit from Rockwell Automation gives engineers one environment to complete the entire machine safety lifecycle, as defined in standards ISO 12100, ISO 13849 and ANSI B11:0.

These tools guide engineers through the steps of the machinery safety lifecycle within one environment, providing documentation to show compliance with international standards. Users can select all elements of an individual safety function, including input, logic and output devices, and will receive SISTEMA (Safety Integrity Software Tool for Evaluation of Machine Applications) calculation files to confirm performance-level requirements are met.