Recommended For You

Drug quality and security are pressing global concerns. And in response, governments and regulatory agencies are imposing ever stricter requirements surrounding the traceability of pharmaceuticals from manufacturing through dispensation. The responsibility for meeting these mandates falls squarely on the shoulders of pharmaceutical companies – who must often retool labeling processes to incorporate new serialization functionality.

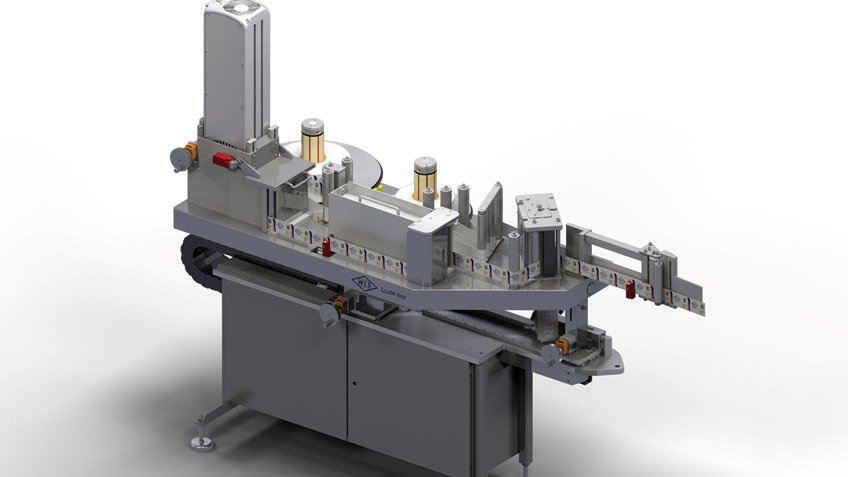

Weiler Labeling Systems (WLS) is focused on helping the pharmaceutical industry address today's challenges. The company designs and customizes advanced pressure sensitive labeling solutions that deliver optimum performance – and printing and vision solutions that support track and trace serialization. WLS, based in Moorestown, New Jersey, has installed more than 400 labeling solutions worldwide during its 20-year history. While conventional indexing labeling heads print lot numbers and expiration dates, the indexed motion limits the speed at which serialization can be done. One of the latest off erings from Weiler Labeling Systems, the WLS X-4S pressure sensitive label head, is designed for high-speed serialization – and new levels of efficiency and flexibility.

Built to integrate with WLS labeling systems, the X-4S enables continuous, on-demand printing of item-level serialization information. “The lot and expiration date are usually constant for the product run,” explained Philippe Maraval, vice president of sales and marketing, Weiler Labeling Systems. “But the new mandates require that labels also include an individual code for each container. These codes are randomly generated from a manufacturer's centralized database.” While printing these item-level codes will soon be an industry imperative, many installed labeling systems simply do not have the functionality required.

Enter the WLS X-4S label head. Appropriate for both inline and rotary systems, the compact X-4S label head can be configured with various coding options. It features a web tension and feed control system from the unwind through printing to enable continuous-motion code printing – even when the labels are being dispensed in indexing mode.

Depending on the size of the code, the label head can achieve speeds in the range of 300 to 400 pieces per minute (ppm). “But it's not just about speed,” Maraval said. “The printed code must appear in the same position on the label each time. We aim for accuracy ± 1/32 inch. Our system is designed for both readability – and repeatability.” An independent three-axis mounting system with digital settings enables precise peel plate adjustment and product changeover in minimal time. In addition, a redesigned “closed loop” push-pull system allows for tool-less disassembly – and eases cleaning. All electronics are located underneath the label head to reduce wiring – and help enable easy installation of the head on a new or existing labeler base. When powered by Rockwell Automation, the X-4S includes Allen-Bradley® Kinetix® 5500 EtherNet/IP™ servo drives and Kinetix VPL low-inertia servo motors.

The label head is integrated with a WLS labeler using an Allen-Bradley CompactLogix™ programmable automation controller running on an EtherNet/IP network. The On-Machine™ solution also includes Allen-BradleyArmorBlock® I/O. “The compact Kinetix motors and drives help us minimize the footprint of the system,” said Vu Huynh, principal controls engineer, Weiler Labeling Systems. “And since the Kinetix 5500 drive has just one cable for both power and digital feedback, we are able to reduce wiring as well.”

The control system is built for rapid system feedback to enable high-speed syncing with motion. “Feedback speed is critical for accuracy and repeatability,” said Huynh. “Given the speeds we are running, print registration could quickly be compromised if the system couldn't process feedback quickly – and automatically adjust.” As Weiler Labeling Systems introduces the X-4S label head, it looks forward to meeting the diverse requirements of the pharmaceutical marketplace. “Our systems are all customized to some degree,” Maraval said. “The Rockwell Automation team helps us address those needs. The worldwide support Rockwell Automation provides is also an advantage for our customers,” Maraval continued. “Of course, we support our customers – but we can also call on Rockwell Automation to help solve unique application challenges.”

For more information, contact: Philippe Maraval, Vice President, Sales and Marketing Weiler Labeling Systems Phone: 856.273.3377 Email: pmaraval@weilerls.com

Published September 1, 2014