Recommended For You

If variety is the spice of life, there's no better example than today's supermarket shelves. Enter any store and the assortment of products is almost overwhelming. For those consumers who have diffi culty making a choice – or simply want to sample a limited quantity – variety packs are an attractive option. The FlexPlace™ reciprocating vacuum placer from Graphic Packaging International helps manufacturers meet the unique challenges of variety pack-type applications – and more.

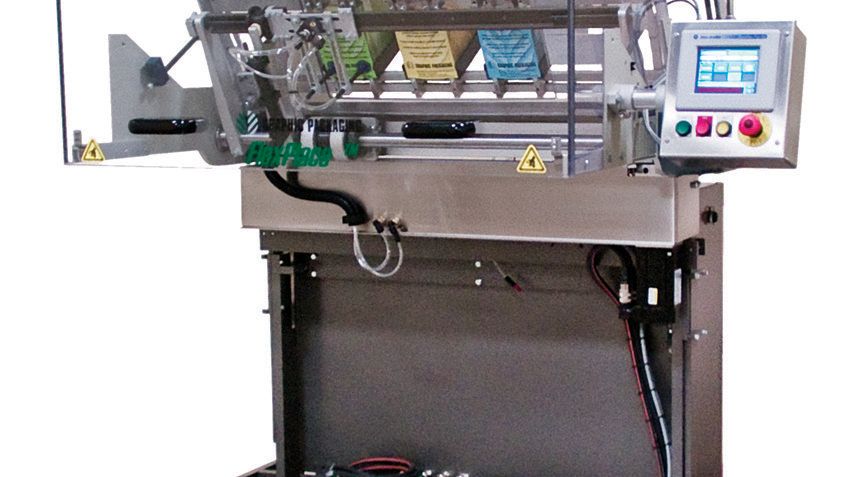

Graphic Packaging International (GPI) is one of the world's largest providers of folding cartons, beverage cartons, unbleached paperboard, coated recycled board, microwave packaging and machinery. As the newest member of the company's pick and place product line, the FlexPlace machine off ers placement flexibility for applications ranging from food and beverage to direct mail. A key component for secondary packaging lines, this equipment features a reciprocating placing head with transversing vacuum stems, an inclined product magazine, operator interface and base – in a compact footprint. Simply put, the transversing vacuum stems pick product from the multi-lane magazine and accurately place it on packaging material entering the system via conveyor.

While many machines on the market rely on intermittent motion for similar applications, the FlexPlace machine operates in a continuous motion environment. “Continuous motion is the key,” explained Gerald Geisenhof, engineering manager, Graphic Packaging International. “The vacuum stems pick the product, and the head rotates and moves linearly to match the speed of the target material on the continuous motion conveyor.” Depending on the application, the equipment senses the product to achieve accurate placement. Since there is no need to stop the target for product placement, the FlexPlace machine allows for higher speeds than intermittent motion equipment. The product magazine can be built with multiple lanes to accommodate packaging requirements. Each lane can be loaded with diff erent items, product varieties or the same product. When the lanes contain different items or varieties, the machine performs a collating function for product assembly or variety pack applications. When all lanes run the same product, manufacturers can achieve extended packaging runtime – using just one machine. “Our FlexPlace equipment is customized for the specific application,” said Theresa Lashyro, sales manager, Graphic Packaging International. “We evaluate every situation and modify the product magazines and product contact parts to meet specific requirements.”

In fact, unlike many pick and place machines, the GPI FlexPlace machine can accommodate 3D items and large, difficult to manage packaging materials – or unique items, such as coins. “For example, our equipment can be used by direct mail or printing companies to accurately place and collate multiple, uniquely shaped materials in a continuous motion line,” said Lashyro. The integrated system is controlled by an Allen-Bradley® CompactLogix™ programmable automation controller, which manages all machine and motion functions. For motion synchronization, the controller is tightly integrated with Allen-Bradley MP-Series™ low inertia servo motors and Kinetix® 350 single-axis EtherNet/IP™ servo drives. One Kinetix drive controls the reciprocating motion, the other controls the linear transversing arm. Allen-Bradley Guardmaster® safety relays help provide machine and personnel protection. The system is integrated on an EtherNet/IP network and monitored using an Allen-Bradley PanelView™ Plus 6 graphic terminal. “No doubt, the Rockwell Automation components help us improve system flexibility,” said Jeremy Houck, controls engineer, Graphic Packaging International. “The easy-to-use operator interface enables recipe-driven product changeover.”

In addition, the machine features quick-change magazines to speed mechanical modifications. While changeover on similar equipment can take 30 or 40 minutes, the FlexPlace machine can typically be ready for a new product run in five minutes or less. “We apply Rockwell Automation products because of their ease of use – and our customer preference,” said Lashyro. “Our customers ask for Rockwell Automation controls, and the products and support are consistently and readily available.”

Published September 1, 2014