Recommended For You

For executives across the manufacturing sector, making innovation-related decisions often presents a tug-of-war between the need to maintain existing systems and the imperative to empower the new capabilities that can really move the business forward. Investment in digital technologies has been high on the agenda for business leaders, who’ve been looking for ways to protect and grow the long-term value of their company’s work.

Given current global circumstances, companies in the sector have been driven to consider such investments more decisively. Against a shifting landscape, they’re seeking to fund initiatives that will help facilitate new and improved ways of working in the short term, while expanding the possibilities for future growth and development.

Challenge Accepted

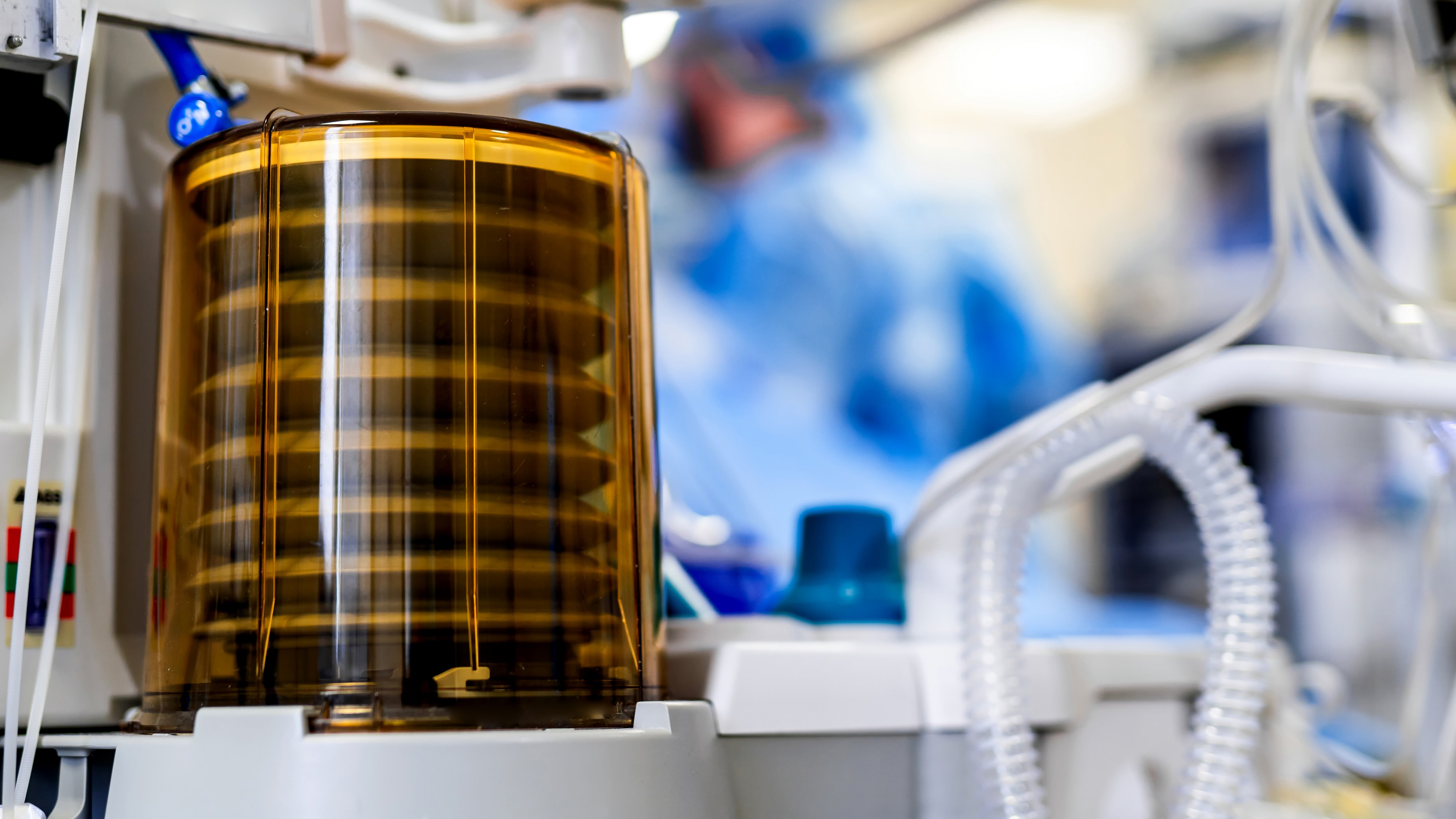

The experience of recent months has taught us that flexibility is a valuable commodity. As priorities suddenly shifted in March, those businesses able to make nimble and well-calculated decisions reacted with far greater speed and purpose. An illustrative example of this was the UK Ventilator Challenge; a consortium of industrial, technology and engineering businesses from across the aerospace, automotive and medical sector. These joined together with the shared goal of serving the country’s urgent need for medical ventilators.

The speed at which the response was activated was nothing short of incredible. It highlighted the enormous potential of advanced manufacturing capabilities, such as augmented reality (AR), which was used to capture and share technical expertise between the members amid restricting circumstances. The fact that companies in the consortium received formal orders from the UK Government in excess of 15,000 units within the programme’s initial months is testament to the creativity and determination involved in overcoming seemingly insurmountable obstacles.

The consortium’s efforts will likely be crystallised as a best-practice study of why manufacturers need to digitise their operations. From my first-hand perspective of its achievements, combined with how I’ve seen many others in the industry position themselves for change, there are five specific areas I’d highlight that executives should focus their attention upon.

1. Resilience

Your company’s resilience is its capacity to endure difficult circumstances and recover quickly. Assessing how well your assets – human and technical – will perform under increased stress requires an assessment of your ‘digital thread’. Think about the processes and informational flows that run throughout your organisation and across your network, from design through to the shop floor, and connecting into your supply chain and through to your product out in the field. What latent barriers and hindrances exist? Can this digital backbone remain robust and resilient in the face of future adversities? Should your business priorities suddenly change, are you capable of fast and nimble decision-making within your current framework? Any vulnerabilities apparent in times of calm, however nascently, will likely be exacerbated in a crisis situation.

2. Scale

‘Start small’ has become a worn cliché in discussions around transformation, but it does point to an important truth: there is no singular ‘transformation’, but a series of changes and initiatives that contribute to advancing the company’s capabilities. The most pragmatic approach, therefore, is to identify a known business problem and apply the technology to it to see some immediate returns. Based on the outcomes and learnings, you can then seek to create a template that can be replicated across business lines and production sites. This will help ensure consistency and create efficiency gains, enabling a positive feedback loop to build from each small step in the transformation journey.

3. Business Impact

As impressive as the technologies are in themselves, it’s important to look at them through the lens of their potential business impact – do they facilitate productive environments? In practice, it’s not technical features that generate results; it’s about proving their value within a business context. It’s therefore imperative that you define the business value of your technology spend ahead of deployment. Considerations around whether the investment is going to save money for the business, improve outcomes for staff and help build libraries of resources that will produce ongoing value are critical components in building a compelling case for change.

4. Collaboration

The future of business mandates greater collaboration with a range of partners that help engender a prospering culture of innovation, such as with research partners and service providers. Ask yourself: Does our technology platform support this ecosystem? How can we architect it so that integration and collaboration is both simple and secure? Think at multiple technical layers, from the use of AR to share knowledge and expertise, down to the use of cloud services to support the massive data demands of machine learning and predictive modelling.

5. Co-existence

The adoption of new technologies and platforms should be part of a gradual process of change. Rip and replace isn’t a viable strategy for many manufacturers that have invested heavily in equipment with long lifespans. Being able to adopt state-of-the-art technologies now that wrap around, and even support, your core IT and operational technology (OT) systems will allow you to gain access to innovation while making longer-term plans for the upgrading of your legacy equipment.

Taking the Long View

When looking for the ‘next big thing’ in manufacturing technology, it’s often not whether the technology is ready, but whether you’re ready. Many of the digital technologies that will define the next decade are already well advanced on the upslope towards full maturation, and are well positioned to become commonplace in industrial environments in the wake of the current situation. As restrictions around COVID-19 ease and the fog clears on future roadmaps, now is the time to look to the long term and seek the capabilities that will make a real difference.

Understanding which technologies will offer the utility and value you intend requires a dual view of what options there are in the field and how they can best be architected to suit your needs. The Rockwell Automation and PTC alliance is supporting manufacturers to rise to this challenge and to reap the benefits of digital transformation.

Published July 20, 2020