“From a technical perspective we have seen mutual evolution too, with our application highlighting a niche but quite important networking synchronization issue, which the Rockwell Automation engineers fixed with the next patch release.”

Based in Dundalk, Co. Louth ControlSoft Automation Systems Ltd provides turnkey PLC and SCADA solutions for Process Control requirements and Energy Management for a broad range of industries including Data Center, Marine, Food and Beverages and Pharmaceutical. Its highly experienced team of Engineers has a wealth of knowledge across various fields, giving it cross-discipline capabilities when integrating systems from numerous areas, including networking hardware and database storage with reporting.

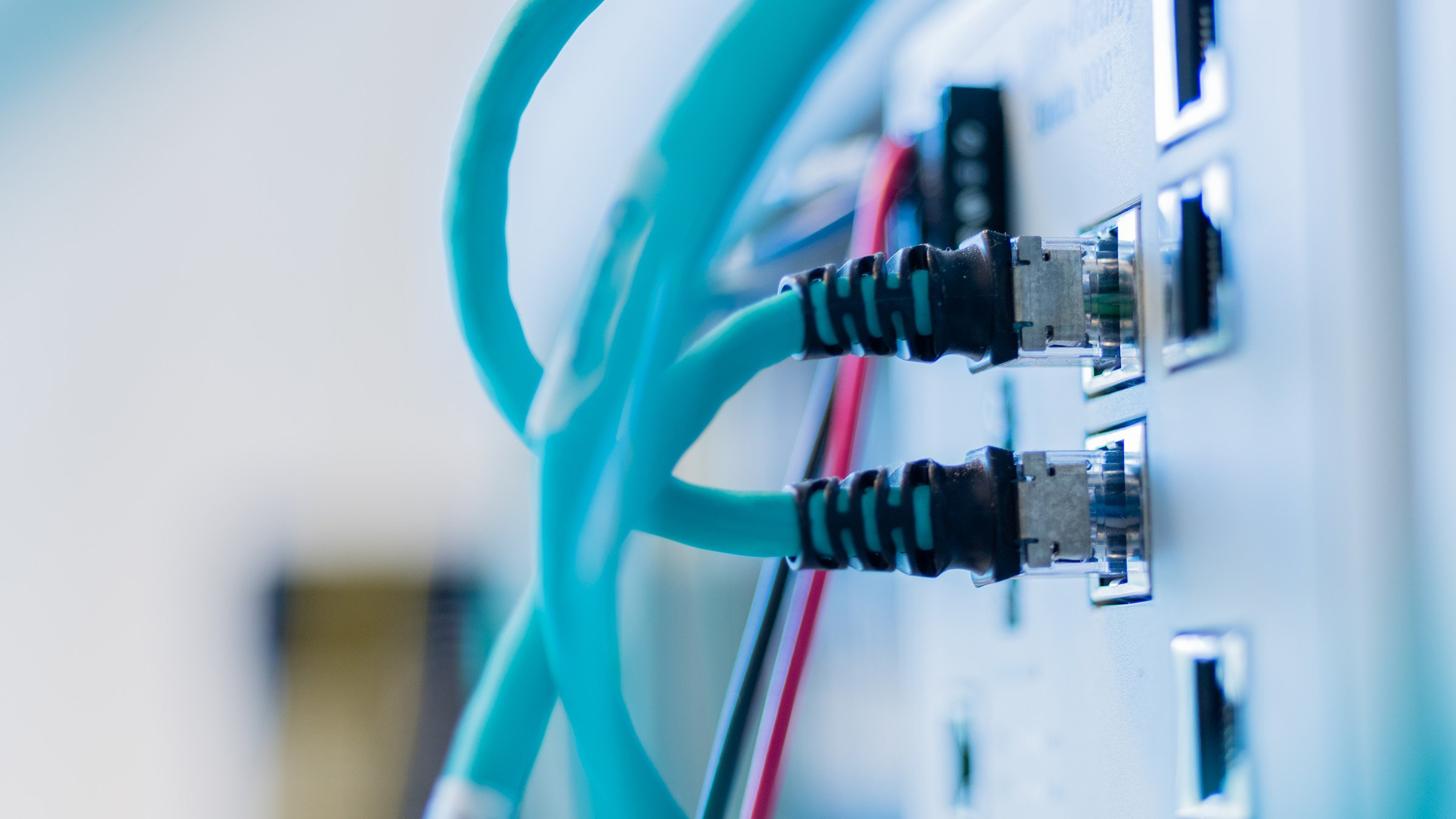

A global datacenter operator and cloud solutions provider needed a far more accurate electrical supply monitoring solution in order to maintain 100% uptime targets.

- Allen-Bradley ControlLogix programmable automation controller

- Allen-Bradley Micrologix PLC

- ArmorBlock I/O & Stratix Ethernet switches

- Power meters

- FactoryTalk View SE & Historian

- Greater uptime confidence

- Far quicker event polling for more accurate identification of exact issues

- Highly scalable

- Easily adaptable with programs stored in PAC

- Open platform

Challenge

Much like gas, water and electricity, it would be hard to imagine modern life without the internet and all the services it delivers. In many instances we now simply take it for granted; it’s just always there.

It has such a profound effect on our every-day activities that it is now all-encompassing, influencing all facets of life, from simple text messages, through photo storage and online shopping and onto international business transactions and remote real-time AR simulations in industrial environments.

Like any utility, the internet relies on reliable connections and robust storage solutions. If either of these are found wanting, daily life starts to struggle, and questions start to get asked. Who doesn’t shudder when they hear the kids yelling that the Wi-Fi is down?

One of the ubiquitous benefits the internet has given us is cloud storage. We no longer need terabytes of local hard drives in PCs or in on-site network storage systems. We can take our work, our photos and our engineering schematics anywhere, and share them easily with anyone.

According to Statista, the total amount of data created, captured, copied, and consumed globally is forecast to increase rapidly. In 2020 it was 64.2 zettabytes and up to 2025, global data creation is projected to grow to more than 180 zettabytes. This massive growth in data and the proliferation of cloud storage services and providers mean that data farms and data centers are cropping up all over the globe.

Unlike gas, water and electricity, which are legislated locally and can face fines from regulators in the event of service interruptions, when data centers fail to deliver, they must face the wrath of their clients and all the resultant contract penalties, PR fallout and loss of goodwill. Indeed, headlines highlighting service interruptions and website blackouts are starting to appear more and more above the fold.

In the vast majority of cases, multiple levels of redundancy are used to store the data, but the datacenters can still be affected by power fluctuations and interruptions, which must be detected and mitigated in as short a time as possible.

The issue is that most building management systems (BMS) are not built to deliver the reactivity data centers require, with polling periods of even just a few seconds delivering thousands of data points. The question being, which signal was first, and which one indicates the issue?

It was these performance limitations, coupled to a lack of support resource from other automation suppliers, that prompted a leading global data storage and services company to contact Irish company ControlSoft Automation, asking it to “dig them out of a hole”.

Solution

Purpose:

ControlSoft had already built a reputation as a problem solver and over the past decade had developed an Electrical Power Management System (EPMS) which can record the usage of over 500,000 electrical parameters, giving its customers a precise picture relating to the performance of their electrical supply.

According to Dermot Carragher, Managing Director at ControlSoft: “The EPMS system we have developed is effectively a distributed-clock system. Everything is synchronized using precision time protocol (PTP); events are sub-millisecond accurate. A typical traditional BMS system is only accurate to a couple of seconds, so in any two second period it may show multiple events, and you don't know which was the trigger.

“Our EPMS on the other hand timestamps down to the millisecond across the distributed system,” he continues, “so you get the exact sequence of events of what happened and when, which means you can confidently identify the precise issue that may have started a cascade of issues.”

Result

The enhanced capabilities of the ControlSoft solution are down to its deployment of Logix programmable automation controllers (PAC), switches and I/O from Rockwell Automation, which have always been designed to operate in the sub-millisecond realm.

Carragher and his team have exploited other capabilities from the Logix-based operating environment too. “The majority of field devices are pre-programmed within the ControlLogix PAC. This means the end user simply has to just configure the installation by selecting the model and node address of the field device being deployed in the data hall and the application will effectively auto configure them without the need for a PLC programmer. This ability to rapidly scale and roll-out installations is an essential element of our platform and was central to our success with the large datacenter client – who needed a solution really quickly. When deadlines are less stringent, this approach allows for easier, less expeditious mass roll outs.”

The openness of the system means it can be adapted for almost all applications. This also addresses many customers’ requirements not to be tied to single power-control component suppliers or brands. It also offers remote-access capabilities, which ControlSoft can leverage – when required and with the appropriate client permissions – to perform programming, maintenance, enhancements and upgrades.

“In this project the timescales were incredibly short,” Carragher explains. “The verbal specification from the client could best be described as ‘on the fly’ and ‘very loose’, but with the help of the Rockwell Automation commercial engineering team we were able to deploy the first phase, which passed validation and worked out of the box.

“We were then told that two more installs were required by the end of the month,” he continues, “but not to worry, as it was all the same. It wasn’t… almost everything was different. The only common components were what we were bringing to the plant. Fortunately, thanks to the scalability of our system and the adaptability of the Rockwell hardware, what should have taken months took just a few days.

Published June 10, 2024