Countless Scenarios

A digital twin provides great opportunity for use in numerous manufacturing applications. The three phases in which digital twins are typically applied are design, operation and maintenance. Adding to the complexity of those options are the reality that digital twins can deliver countless scenarios. For example, you can have a digital twin of a device (such as a drive or motor), process, manufacturing cell or machine, entire production line, plant or a series of plants (enterprise), people and customer behavior. Plus, no two are exactly the same.

To tap the potential of a digital twin, first make sure you and users agree on the goal. Value comes from talking about the problem and agreeing on how to use the digital twin to solve that problem. For example:

Could the digital twin you developed to design a product be used to predict when maintenance will be required?

Could the digital twin of a device be used in a digital twin of the operation of a machine or production line?

If you are using a digital twin now, you are surely already realizing the benefits. However, there is more if you expand your usage and find ways to leverage the digital twin between phases.

Digital twins can create greater opportunity for manufacturing efficiency and the foundation for predictive maintenance so you can maximize productivity.

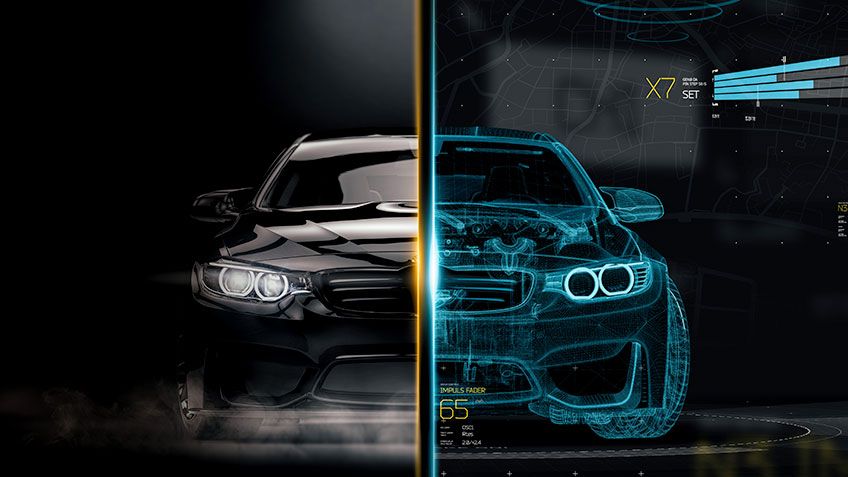

Real-World Relevance

The digital twin virtually mimics a company’s machines, controls, processes, workflows and systems. Through experiments and improvements on the digital twin, manufacturers gain insights into potential real-world behaviors of assets by:

- Experimenting with new equipment configurations to optimize quality, reliability and speed — well before machines are prototyped or built

- Trialing line startups and production scheduling/sequencing to optimize product mixes and volumes from a plant or plant portfolio

- Allowing production employees — managers, frontline operators, and maintenance technicians — to virtually operate and maintain new equipment and lines, minimizing costly startup problems (poor quality, safety, machine stoppages) in the real world

- Diagnosing and solving equipment and process problems before they occur, and experimenting virtually with rapid changeover techniques to boost uptime and productivity. Later, as equipment operates, continuous-improvement teams monitor data streams from embedded smart devices to further improve workflows, changeover times and overall operations.

Rockwell Automation has helped numerous organizations apply and leverage digital twins.

For example, a food manufacturer tested and validated a facility upgrade prior to implementation, helping it achieve 80 percent less downtime and a throughput increase of more than 10 percent.

Another large multinational virtually tested production scenarios (e.g., increasing output for a product promotion, changing to less costly production materials), saving millions of dollars with the same equipment.