The Port of Newcastle is the largest bulk shipping port on the east coast of Australia and the world’s leading coal export port. Newcastle Coal Infrastructure Group (NCIG) owns and operates one of Australia’s major coal export terminals with proximate rail, storage and shiploading facilities and associated infrastructure.

NCIG’s terminal has been operating since 2010 and services coal mines in the Newcastle, Hunter Valley, Gunnedah, Gloucester and Western Coalfields of New South Wales by providing access to port infrastructure to export mainly their thermal and sometimes metallurgical coal production to the world market.

To meet the requirements of growing exports from the Port of Newcastle, the Terminal was expanded to provide an overall export capacity of 66 million tonnes per annum (Mtpa) in June 2013.

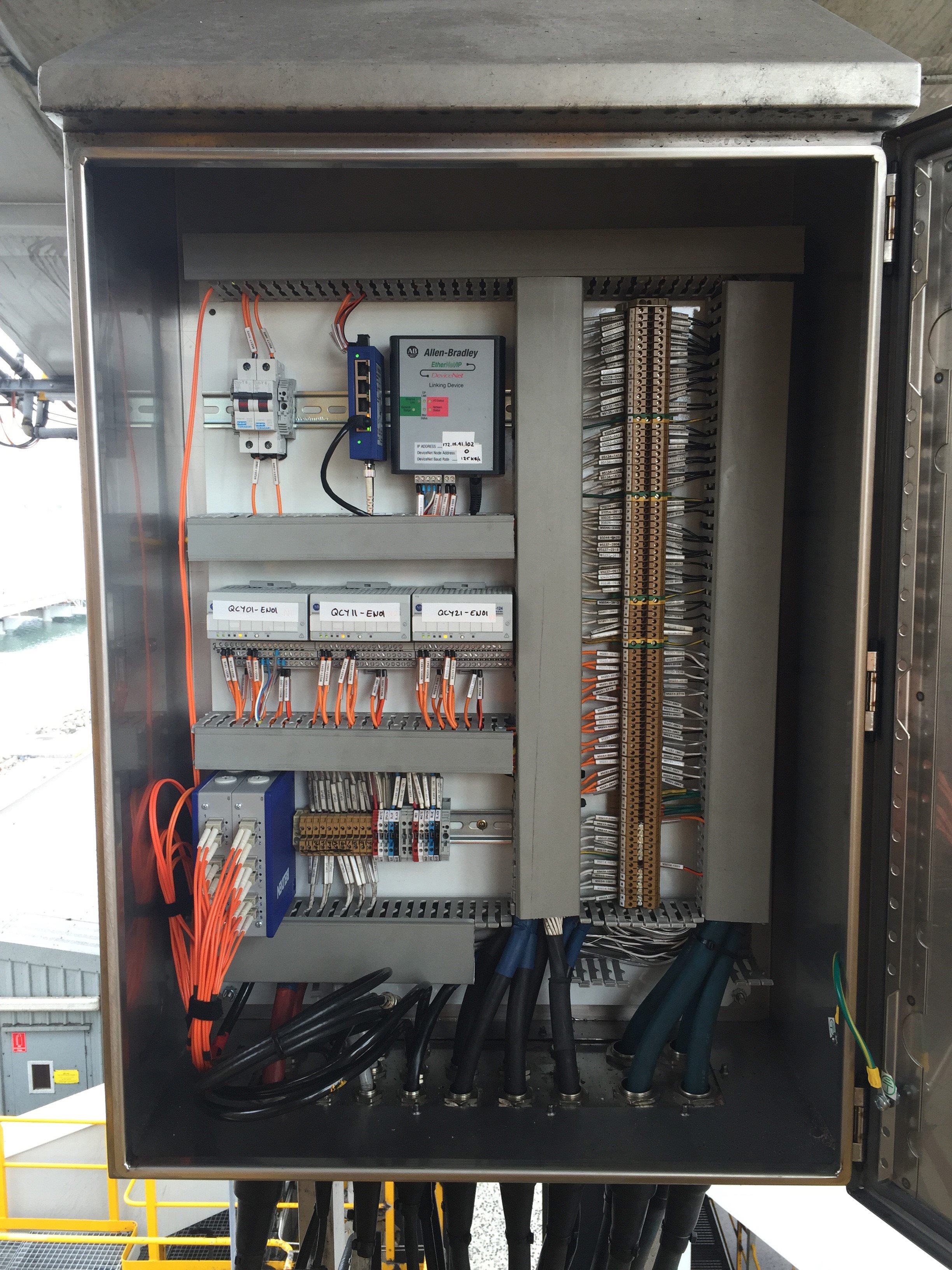

A key focus of NCIG’s operational strategy is to operate continuously, 24 hours a day, seven days a week, with the minimum number of staff. To achieve this, the latest integrated control systems were required to provide site wide access to condition monitoring data in a timely manner. The Integrated Architecture® platform from Rockwell Automation allows for the seamless integration of vibration and temperature monitoring sensors, providing the capability for NCIG to implement a preventative condition based maintenance strategy.

Predictive Monitoring perfection

There are three key components of the NCIG terminal; the inbound system, stockyards and outbound system. The inbound system unloads trains and feeds coal into the stockyard area, it incorporates rail sidings and rail balloon loop, dump stations and two inbound sampling stations. There are five stockyards in total with four combined stacker reclaimers. The stockyard provides for stacking coal, then storing the coal before reclaiming the coal to send to the wharf. The outbound system loads coal into vessels and incorporates two buffer bins, two outbound sample stations, two shiploaders and three wharves.