Smart VFDs help reduce downtime

With a smart VFD, engineers can set analytic models to measure equipment speed or other characteristics. Plus, they can use remotely accessed data to identify potential maintenance needs. When examining three pumps that are running at the same speed, an engineer could notice that one pump has a lower load torque. As a result, a technician could be sent to investigate the issue. VFDs with remote data visibility help:

- Reduce downtime and maintenance costs

- See predictive life alerts based on embedded analytics for critical components

- Confirm drive component runtime hours and maintenance requirements

Plus, when PowerFlex 6000T VFDs are combined with FactoryTalk® Analytics™ GuardianAI™, operators get an expanded view into the health of plant assets, including:

- Predict and identify pump, fan or blower failures

- Get notifications of flow restrictions, cavitation, loose mounting, blade misalignments, bearing faults, etc.

Where medium voltage drives provide the most value

Energy-intensive industries, such as petroleum, metals, minerals, food, paper and chemicals account for over 50% of global industrial energy use and offer countless opportunities for smart motor control solutions.

PowerFlex medium voltage drives can control motors for pumps, compressors, conveyors, blowers, extruders, fans, mixers, cranes, hoists, chillers and propellers. And each application offers the opportunity to reduce energy use.

The opportunity to apply sync-transfer control for pumps in the water, wastewater, oil and gas industries is enormous. One Rockwell Automation customer in the energy industry uses more than 100 medium-voltage drives – and most operate sync-transfer systems.

Top 3 sync-transfer motor control benefits

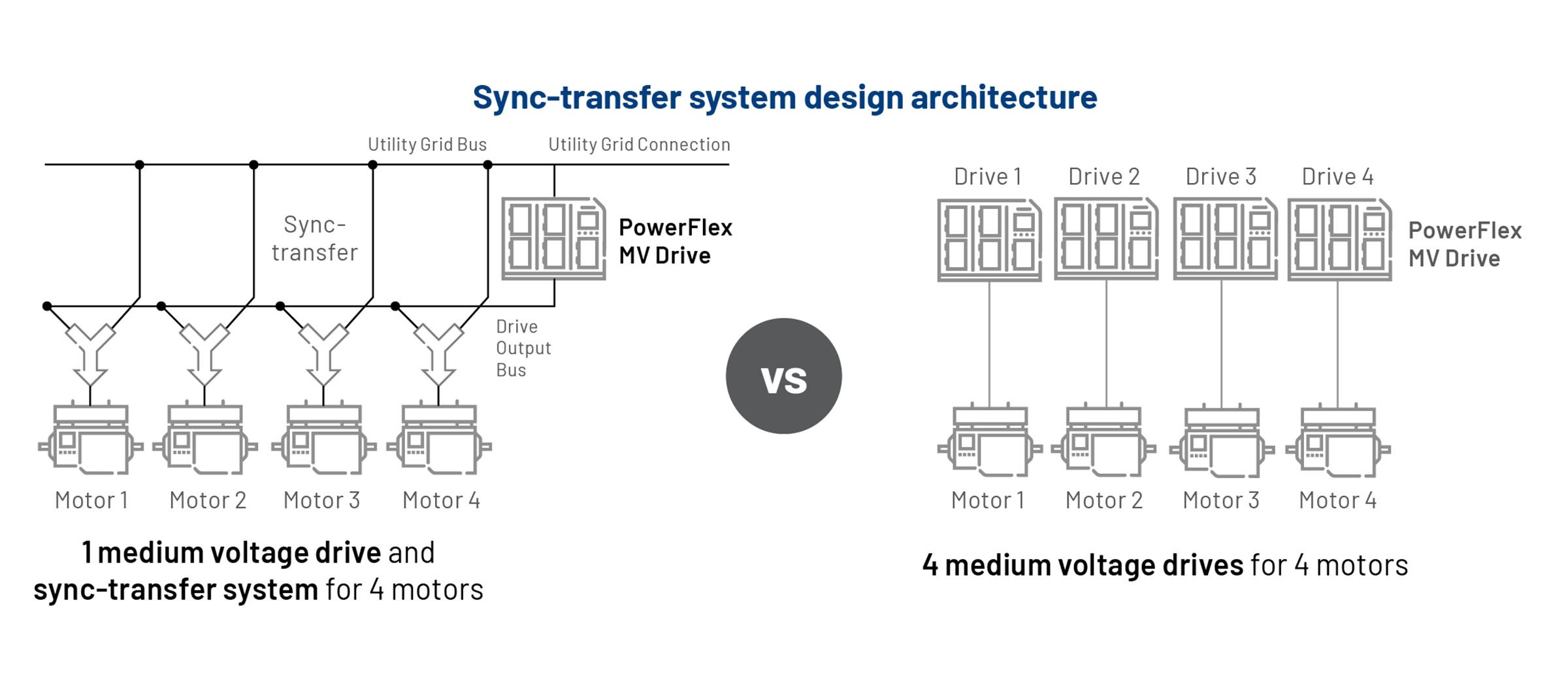

Do more with less equipment. PowerFlex 6000T and PowerFlex 7000 VFDs with sync-transfer control help:

- Save energy. Combine the efficiency of the VFD with seamless sync-up and sync-down transitions and reap the energy-saving benefit of direct-on-line operation at optimum speed. Reduce peak energy charges. Reduce VFD power losses because the size and number of VFDs are reduced

- Save time. Reduce time and costs designing multi-drive systems – specifying, purchasing, shipping, installing, commissioning and maintaining additional VFDs

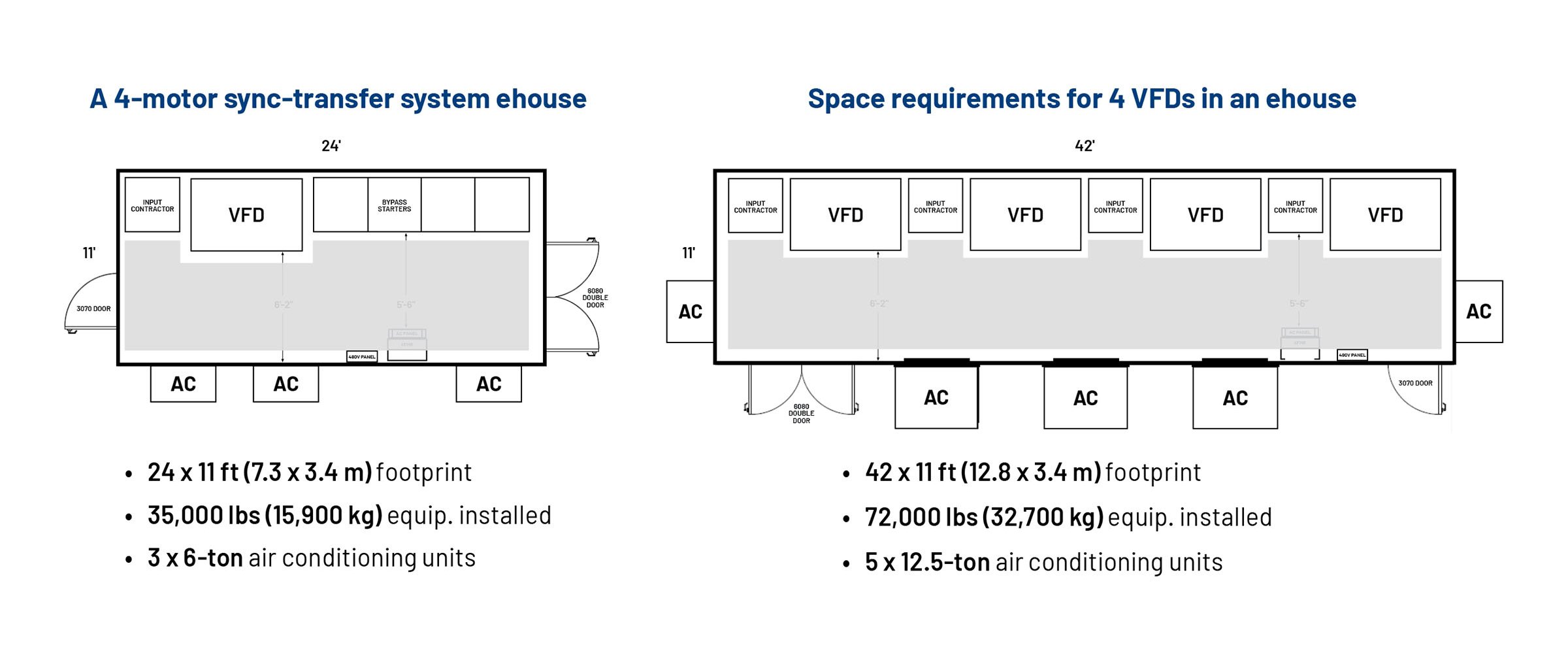

- Save money. Reduce both capital and operational costs. It costs less to buy, house, power and cool one MV drive with a sync-transfer system versus multiple variable frequency drives

Rockwell Automation has offered sync-transfer systems with medium voltage drives since 1989. Several hundred sync-transfer systems have been implemented worldwide.

By delivering precise motor control and real-time process data with predictive maintenance alerts, smart VFDs can help achieve your production goals. Learn about PowerFlex medium voltage drives online. There’s an MV drive solution that’s right for you.