Recommended For You

Challenge

- A tissue paper packaging manufacturer, like other competitor companies, was facing slow, manual changeover times based on its mechanical production system, negatively impacting productivity.

Solutions

- Provides independent control of multiple movers on straight or curvilinear paths

- Replaces rotary driven chains, belts and gears with software

- Redefines speed and flexibility in production automation

- Lessens downtime on changeovers

- Ensures shorter runs can remain profitable

- Lowers periodic maintenance and reduces machine size

Results

Greater productivity

- Process changeover times were reduced from hours to minutes

- Wrapping quality significantly improved on high speeds by changing from intermitment to full flow wrapping technology as a result of using iTRAK system.

- 10-20% increase of production speed but also around 40% increase of overall efficiency.

- STAX is now recognized as a technological and the highest competitive leader in the industry.

- Enhanced its corporate image to become a major international player

- Opened doors with partners from the Rockwell ecosystem, such as Kimberly Clark

About STAX

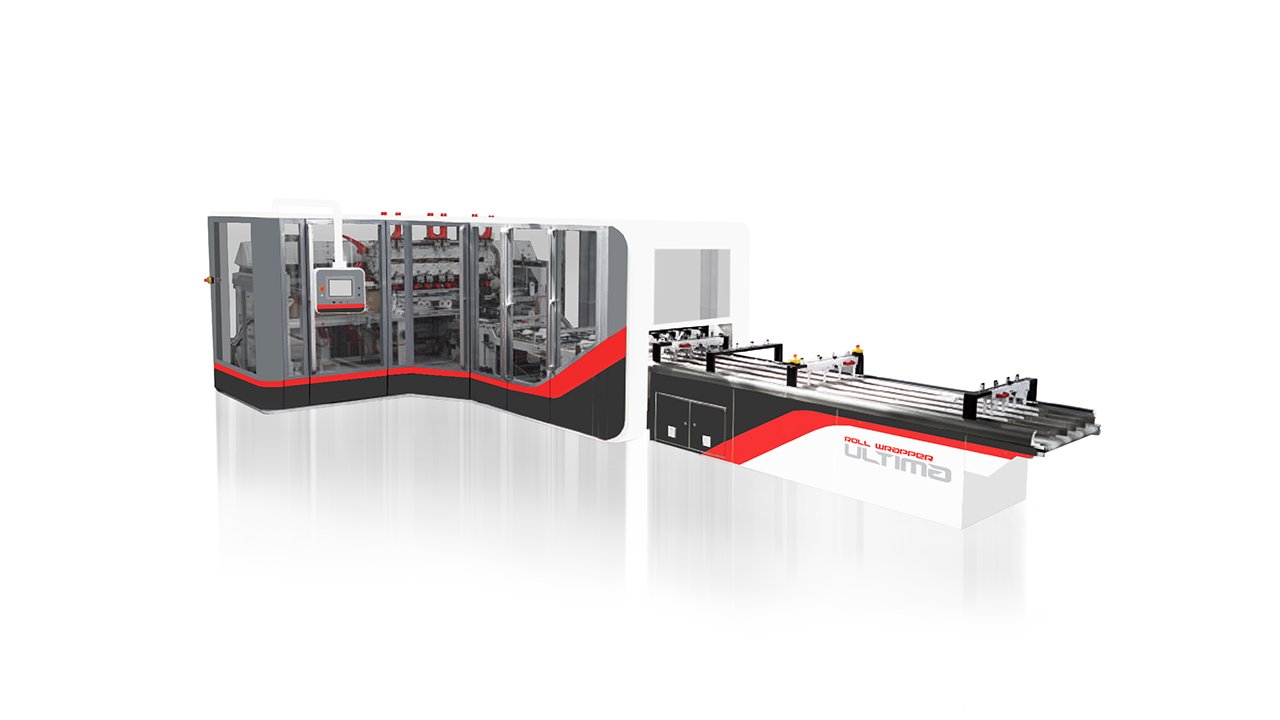

STAX Technologies is a Serbia-based market leader in the tissue packaging equipment industry, whose core product offerings include wrappers, bundlers, casepackers and palletizers. Since its foundation in February 2002 in Cacak, STAX has built a global customer base and continues to deliver innovative and highest technological solutions to the market.

STAX partners with customers to understand their needs and provide innovative technological solutions. It differentiates itself in the market through the swiftness with which it adapts to quickly changing market trends and a high level of creativity and innovation.

The company has a continuous focus on the development and manufacturing of packaging machines for the Tissue Converting Industry. Over the years, by introducing endless innovations, it has become one of the leading companies in the packaging industry. As a manufacturer of supreme automatic systems for the tissue converting industry, it offers complete solutions for packaging of tissue paper for personal care and fulfils specific requests from its clients.

STAX’s goal is to become the global leader in providing packaging solutions in the tissue converting industry.

The problem

STAX, like other competitor companies was facing challenges with both the changeover time and production speed of machines optimised for packaging consumer paper products like kitchen towel rolls and toilet paper.

The conventional machines used in the industry so far had a standard construction containing a chain or belt from which everything is connected. This means that whenever there was a need to switch products, production needed to be stopped. The changeover had to be done manually with tools, which required the end-user to readjust everything, set to the new positions, reassemble and test the new setup, which could easily take up more than a few hours.

Tomas Babka, OEM Sales Manager at Rockwell Automation, explained: “Almost all OEMs still use rotary driven chains, belts and gears to control the system which makes changeovers difficult. You need a technician with the right tools at the right time.”

As a result, the process was quite slow and the mechanical design had to be extremely robust due to big peaks and the time-consuming profile of the entire packaging process.

As Josef Slapak, OEM Account Manager at Rockwell Automation, said: “It depends on the end-user. This machine can be for anybody. Some businesses only use a four-pack of toilet papers through the entire machine lifecycle, so they will not gain much on changeover , but they will be able to use machine on higher speeds getting an excellent package.

Meanwhile, the other producers who need to change the formats more often would end up losing money when the changeover times are longer. Using machines with iTrak is an ideal solution for this problem.”

STAX was searching for solution that would help it bring something special and unique to the market. This would have the added benefit of enhancing its image, and allowing it to be recognized as an OEM provider of highly innovative and high-end technological solutions.

The solution

STAX first encountered Rockwell Automation’s iTRAK Intelligent Track Systems at Automation University in June 2015, and quickly realized it represented a whole new way of looking at production process. On the back of that, it soon gave the go-ahead to the development of a brand-new machine and, following a couple of visits to Rockwell’s Long Island facility, put in an order for iTrak in the summer of 2016. The machine was soon launched at Tissue World in February 2017.

iTRAK is a modular, scalable and linear motor system that enables independent control of multiple movers on straight or curvilinear paths. It enables OEMs to do away with rotary driven chains, belts and gears, and replaces it with simple, effective software that redefines speed and flexibility in automation. As Aleksander Bukvic, Technical Director at STAX Technologies puts it: “The product, as we discovered it, Looked like exactly what we needed to bring our machines to the next technological level.”

The technology helps businesses to improve production rates by 40 percent or more, lessen downtime on changeovers and ensures shorter runs can remain profitable. It also lowers periodic maintenance and reduces machine size.

The results

The hours it took STAX’s customers to change over its production process were swiftly reduced to a matter of minutes with iTrak. This ensures it can produce much more packaging products, much faster than previously possible. STAX’s previous converter enabled it to run 180 packs per minute, but with iTrak it was immediately able to run between 200 and 220 packs per minute.

Aside from effectiveness of the production process, STAX’s corporate image has vastly improved, and it is increasingly recognised as a company that is a unique and valuable partner not only for Rockwell Automation, but other major international players too.

As Tomas explains: “From the very beginning STAX was positioned as a company from Serbia producing proven quality machines for a fair price. But the owner has been able to move it to a higher level and show that it is able to compete with leading OEMs from around the world and build machines on the highest technical level.

The desire to increase its presence in North and South American markets makes the partnership with Rockwell Automation an extremely positive step, particularly given Rockwell Automation’s reputation in these markets.

This expansion has also opened doors with major partners from across the Rockwell ecosystem, such as Kimberly Clark. STAX has recently become a member of Barry-Wehmiller group, which offers even greater potential for growth.

I think using iTRAK has been the best result of STAX’s cooperation with Rockwell,” says Josef. “Using the strengths from the both sides, STAX has set new technological standards in the industry using Rockwell’s iTRAK system.

Published September 21, 2020