Specialist advice on your best way forward

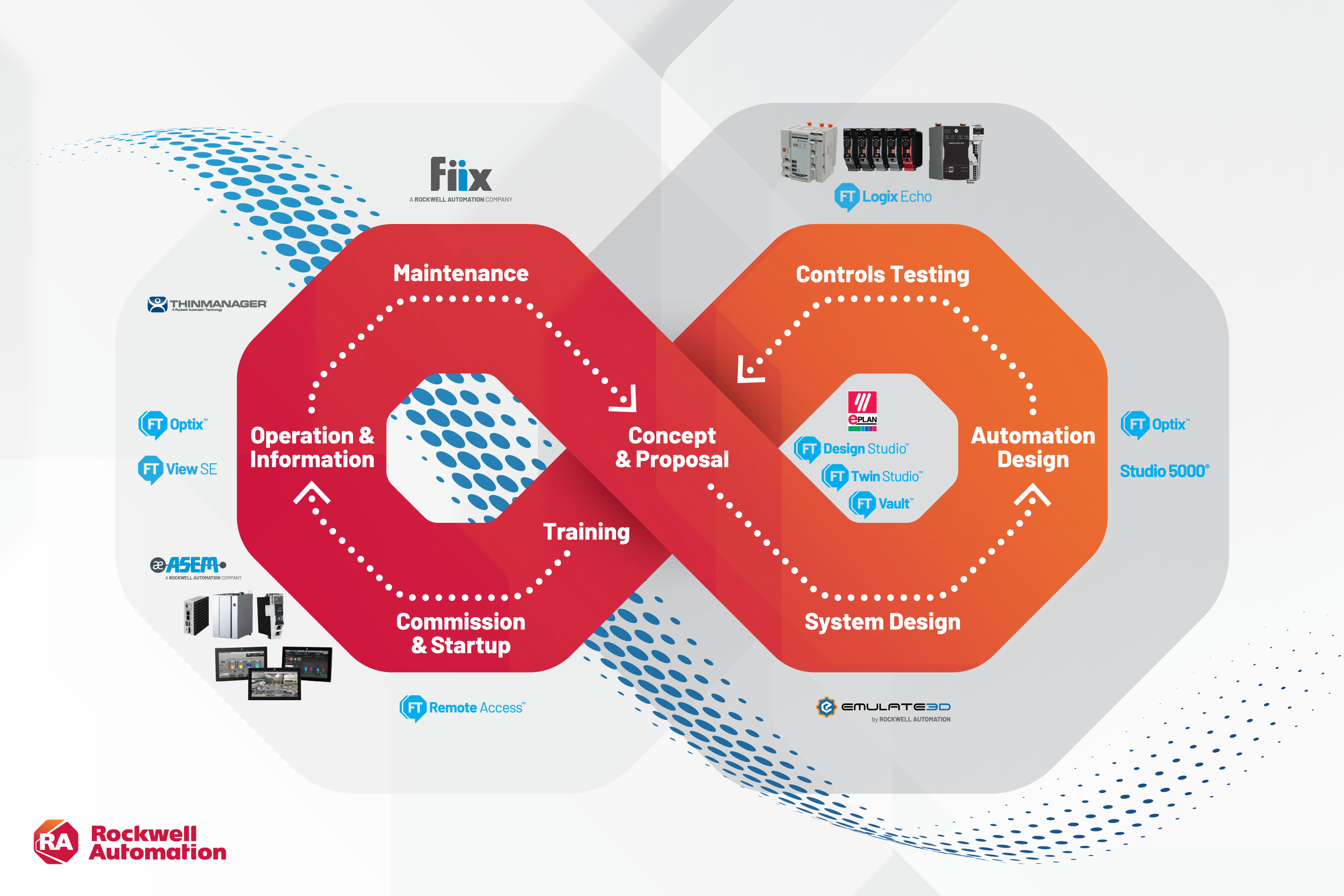

You may already be leveraging Rockwell Automation software and hardware in a number of different stages of your design and manufacturing processes. But are you getting the most from your solutions? And what happens when you complete the loop of data-driven technology?

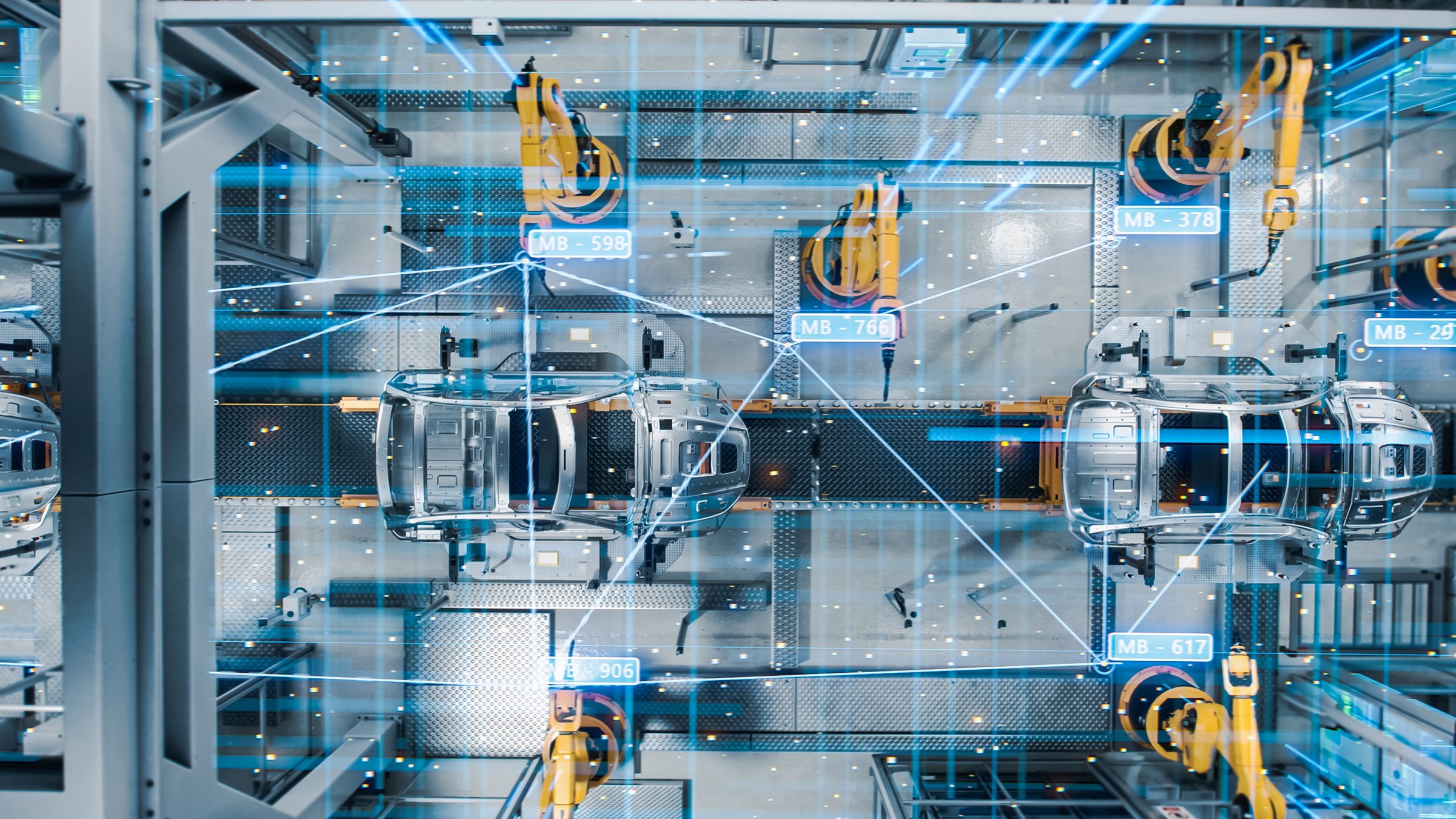

Rockwell Automation’s digital engineering portfolio can help you dramatically shorten your project timelines and accelerate your time to market. Our powerful emulation tools allow you to virtualize, test and refine designs before physical prototyping, eliminating costly and time-consuming rework, and streamlining your entire development process.

Our workshops can be run at your place of business or online, depending on your preferences. At the end, you’ll receive a range of free trials and incentives to help you explore our solutions with your own use cases. Don't miss out – register today!