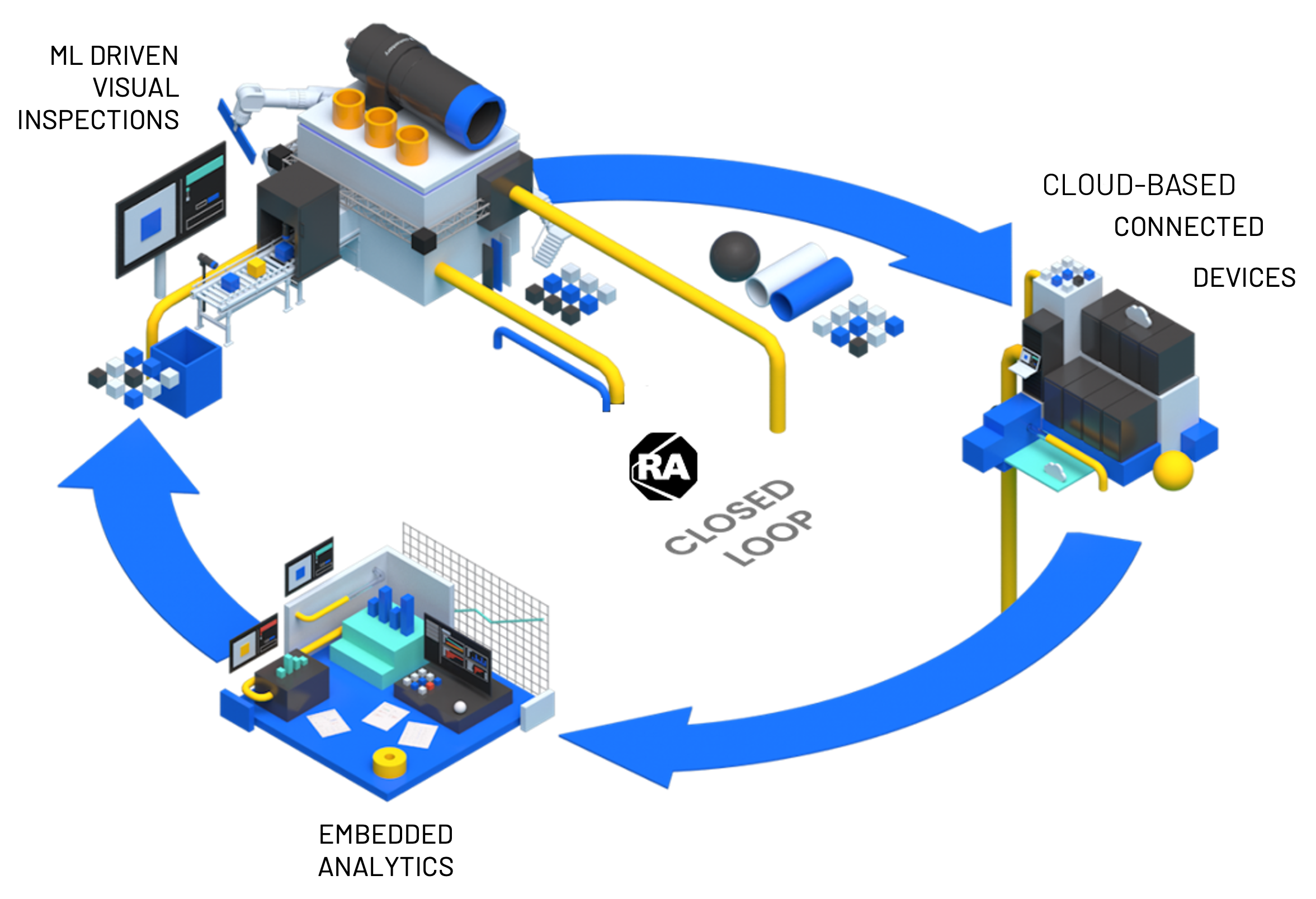

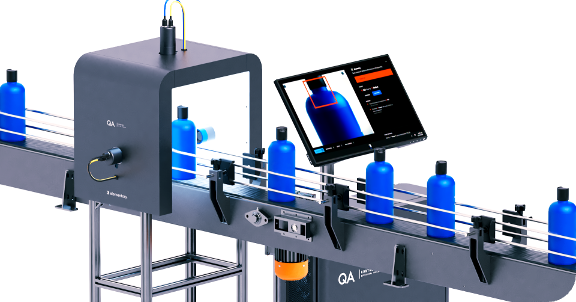

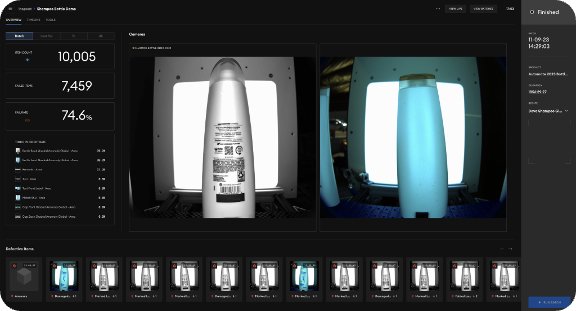

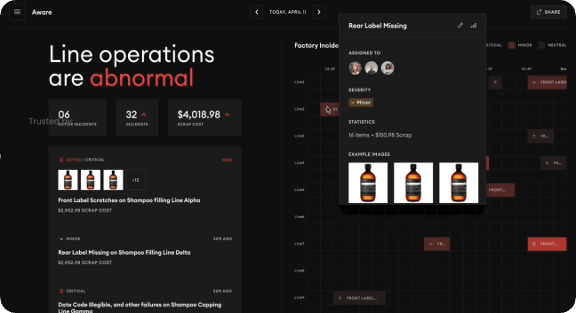

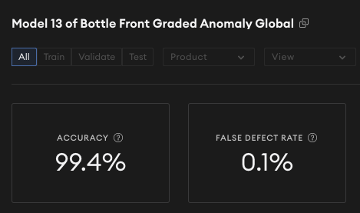

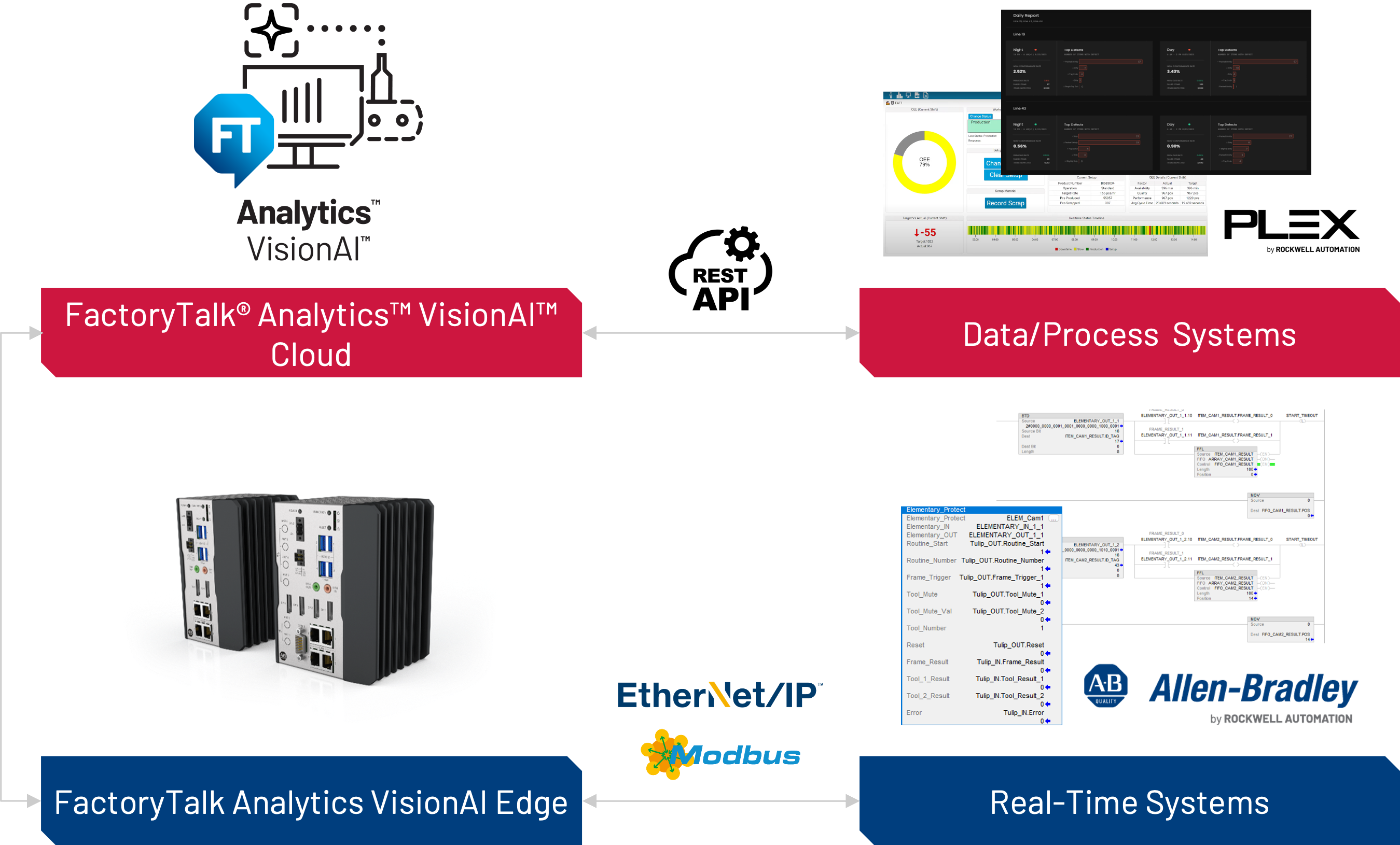

FactoryTalk® Analytics™ VisionAI™ takes a no-code approach to vision inspection to improve quality, maximize yield and gain critical insight from real-time production data.

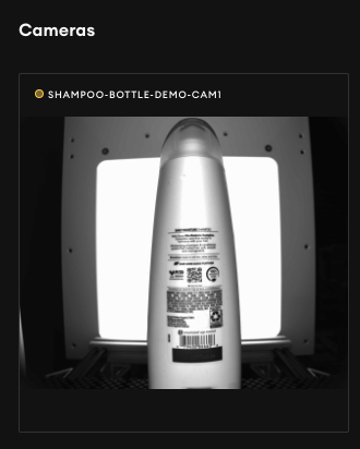

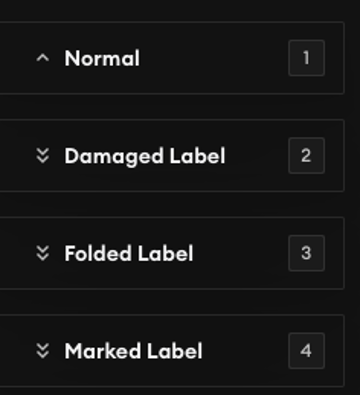

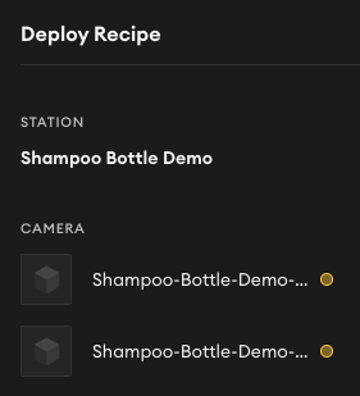

Throughout the entire user workflow (from camera configuration and capturing images to training and deploying models, and even for analyzing quality performance), our machine learning and vision inspection solution helps quality personnel and plant operators view the information they need to achieve their quality performance targets.