Custom Machine Engineering is a Must

Let’s start at the top. Providing custom machines and equipment to solve a customer’s unique challenges is how many custom machine builders have made their name.

That’s especially important today when packaging must be innovative, multi-functional and stand out on the shelf, all requiring new engineering and never before tested concepts. And whether or not a packaging OEM can meet the novel specifications cost-effectively is directly related to their approach to machine design.

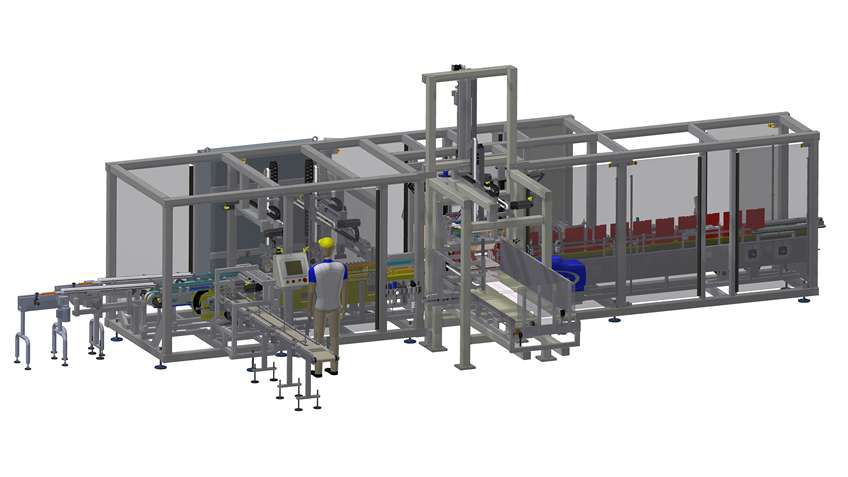

One company is tackling this challenge head on. AFA Systems, based out of Ontario, Canada, is a global leader in engineered packaging automation systems. Not unlike other custom machine builders, engineering is at a premium. Streamlining any part of the design and build process can be invaluable in solving how to reduce lead time. AFA has found efficiencies in embracing a single control platform to integrate complete line, cell and robot control programming, commissioning and maintenance.

Programming in Operational Efficiency

Adopting a single platform allows machine builders to create modular components and standardize on assemblies to get machines into production quicker. It also allows OEMs to take full ownership of their solution, including service and support.

The alternative is the minefield of trying to tie disparate systems together to create one final solution. Multiple suppliers, systems and protocols add unnecessary time, resources and long-term support needs that can strain your technical resources. Leveraging preconfigured solutions and familiarity can save as much as 20 percent on engineering time on a portion of a project. It also allows for faster reconfiguration down the road. And that all adds up.

AFA Systems is an early adopter when it comes to standardizing a single control solution that includes robotics. The company was able to simplify training, operation and maintenance for its customers by using just one control platform for all machine operations. Additionally, machine performance improves with better coordination between the robot and other motion.

The company found that by hiring programmers who are familiar with the same system, in this instance a Rockwell Automation platform, all technology originates from and stays in house. That means AFA Systems can troubleshoot their own equipment. This is a welcome change after experiencing some challenges when coordinating with third-party suppliers to service and troubleshoot their customers as intimately and quickly as they’d like.