One of the largest challenges facing manufacturers is an increasing demand for flexibility and diversified product options. As the research and development are accelerating, product design cycles are getting shorter, with a wider range of products being released in a shorter time, and consumers demanding ever more customization options. Lost productivity due to line changeovers is becoming a major headache for manufacturers.

Traditionally, the development of the assembly line made mass production economically feasible, but at the cost of flexibility. Since each manufactured product must travel down the line at the same speed, the slowest station on the assembly line becomes a bottleneck, limiting production rates. Famously, in the development of the automobile assembly line, Henry Ford remarked that “Any customer can have a car painted any color that he wants so long as it is black.” The decision to limit paint color was made because at the time, the only color that could dry fast enough was black – choosing another color would have slowed down the entire assembly line. Furthermore, any changes in the product design such as the size and shape of the product often meant the production line needs to be rebuilt, leading to huge cost overhead with each change.

A major step forward in flexibility came with the development of independent cart technologies, such as Rockwell Automation’s iTRAK® and MagneMover® systems. This style of conveyance effectively allows for variable pitch processing, reducing the impact of bottlenecks. In addition, independent carts are naturally more modular, permitting improved flexibility and scalability, while reducing downtime from changeovers. Using MagneMover®, products must no longer visit every station on an automation line, allowing for a wider range of products to be made on the same product line, with no changeover downtime. Finally, the fundamental concept on which independent cart technologies are built – linear motors – have fewer moving parts than traditional conveyance solutions, meaning less maintenance and downtime as well as improved processing speeds.

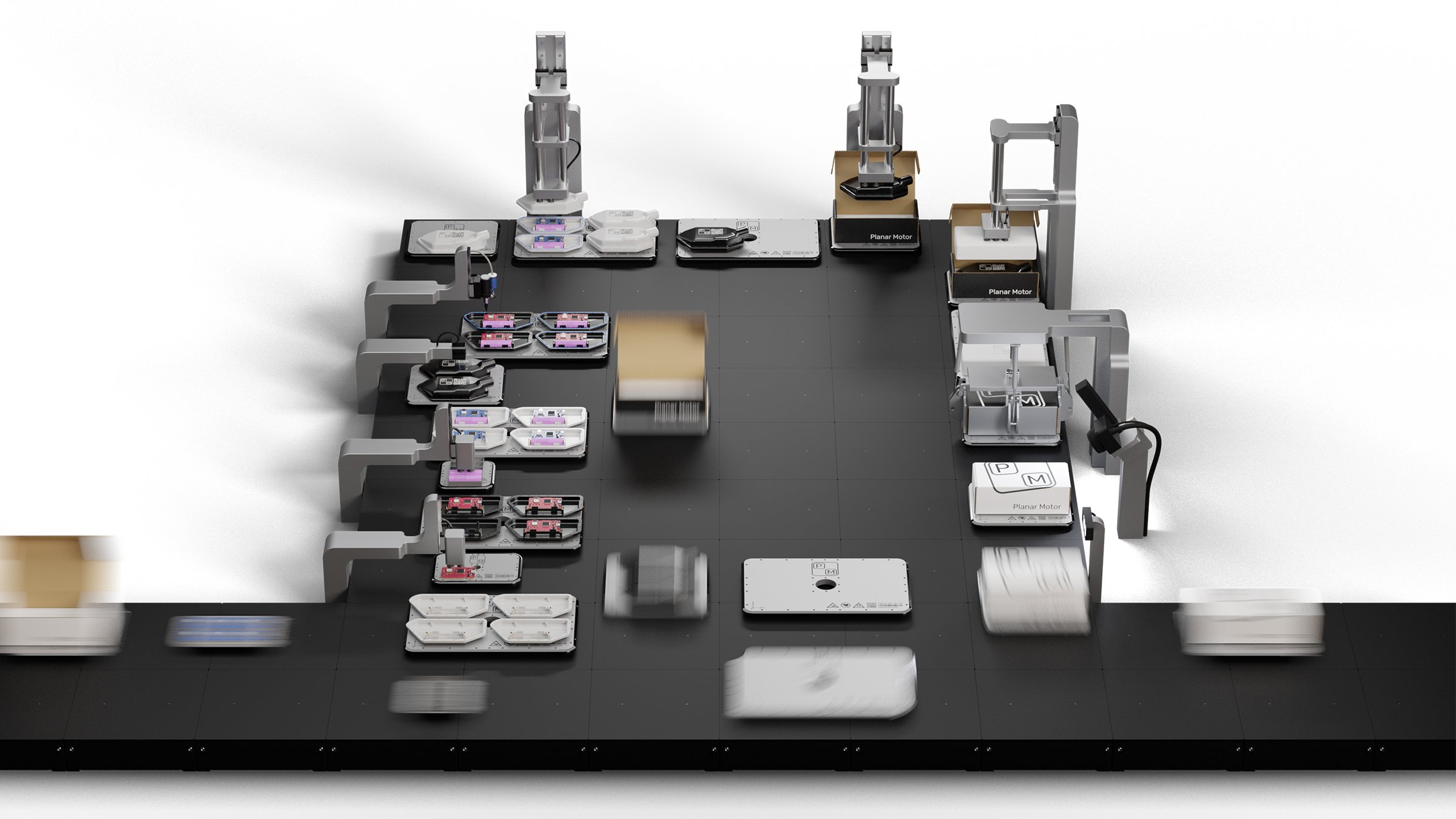

Planar motor solutions, like the XBots developed by Planar Motor Inc, is an additional option for providing flexibility to manufacturers. A planar motor solution consists of a collection of stators laid out in any pattern, and any number of movers, which can move freely across the stator surface. The movers are magnetically levitated, offer 6 degree-of-freedom of control, and typically carry payloads up to 14 kg (30 lbs). Movers are no longer confined to a track, making possible entire new classes of machine designs. As an example, highly customizable applications, where dynamic reconfiguration of processing steps is required, become trivial to implement. As another example, the movers can be easily arranged in 2D for packaging applications. Finally, since the movers can turn on a dime, the floorspace required by the machine is often reduced by an order of magnitude, leading to huge overhead savings for the manufacturer.