Recommended For You

Challenge

- Needed increased visibility into production processes to provide deeper-level reporting for wide variety of customer orders

- Automatic data collection from legacy controllers, each handling a single manufacturing operation

- Need for real-time, granular reports to provide competitive advantage

Solutions

- Manufacturing Intelligence - FactoryTalk Historian SE software for access to production information, operational trends and historical data

- Improved Visibility - FactoryTalk VantagePoint software organizes information from disparate data sources, and provides tools for analysis and reporting

Results

- Improved customer experience, able to view status of order in real time

- New reporting methods for operators to track trends and predict scheduling, reducing downtime

- Improved competitive status

Background

Turning human and animal cells into medicine, like insulin and antibiotics,is a complex, sophisticated process. The transformation occurs in mixers, which separate and help extract vital therapeutic materials.

Stainless steel equipment has long been an essential aspect of this process, but sterilizing stainless steel effectively requires time-consuming and expensive methods. So, life science and healthcare companies often turn to a more efficient and cost effective solution: single-use bags that are inserted into mixers, used during the process, and then thrown away. The disposable bags eliminate the need to sterilize stainless-steel mixers, reduce the potential of cross-contamination, and greatly decrease turnover time between batches.

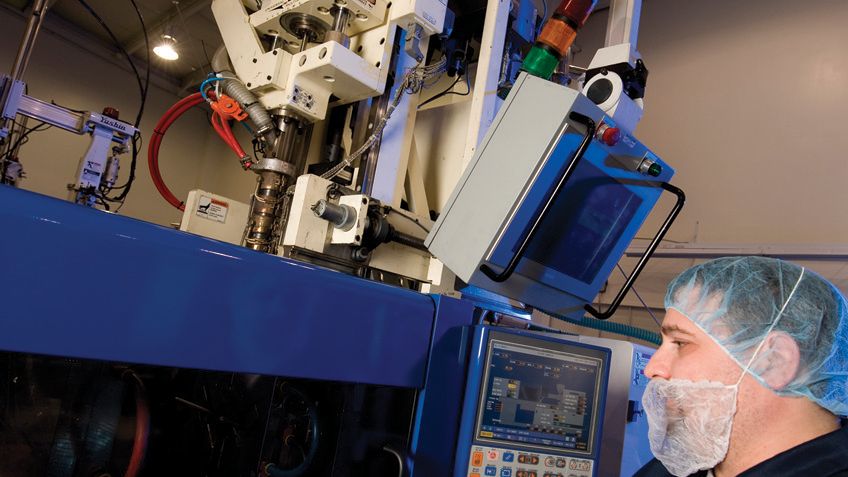

ASI (Advanced Scientifics Inc.) a leading global producer of single-use systems for biotech, is a major provider of these single-use bags to a variety of life science and healthcare companies. The company wanted to improve its data collection and reporting capabilities on bag runs, improve quality control for customer orders, and provide each customer with accurate and up-to-date information on the status of their order.

Challenge

One of ASI's primary competitive advantages is its ability to quickly customize product to meet any customer needs. To maintain this type of flexibility, operators often need to change the configuration of a line to meet the differing specifications, including the size of the order, type of bag and the customer's deadline. With this wide variety of demands, ASI needed greater visibility into their process to optimize production and provide customers with process and production information on their orders.

For part of the process, operators still had to record some data manually. ASI not only wanted to completely automate the data collection and reporting process, they also wanted a more granular view of each parameter in real time. This would allow them greater control over the process and greater visibility into alarm conditions to reduce downtime.

Such transparency is also important for customers. Consistent documentation and accuracy of each run is essential for compliance for life sciences and healthcare companies. So, another goal of ASI's was to be able to produce high-level reports that would provide customers with the insight they needed into the final product.

Solution

ASI needed the right software to meet their goals. ASI turned to Automated Control Concepts Inc. (ACC), a Solution Partner of the Rockwell Automation PartnerNetwork™ program, to design and deliver a solution based on the FactoryTalk® software from Rockwell Automation.

“Choosing FactoryTalk software was a simple decision because we knew it would integrate seamlessly with our existing Rockwell Automation hardware, meaning minimal changes and interruptions to the process,” said Rudy Pavlik, engineering manager, ASI.

FactoryTalk VantagePoint software accesses data from points in a run and allows operators to view various parameters on dashboards in real time, including those once manually collected. ASI can create a deeper-level report for operating managers to track various parameters – including seal-pressure and temperature, trends and machine status – to ensure quality control on a bag-to-bag basis.

Operators can also view the status of each machine on the line – meaning whether it is running, idle or paused – so they can more accurately predict when an order will be completed and when a new one can start.

For customers, ASI can readily create a report containing high-level process data – including temperature, pressure and time – for each individual part produced.

By using FactoryTalk Historian Site Edition software, ASI operators can record and track time-series data to pinpoint operating trends. “By integrating information from individual machines, as well as throughout the line, we can adjust parameters when and where necessary, which improves efficiency throughout the plant,” Pavlik said.

Results

ASI's increased visibility into the process has made operations more efficient and has improved their competitive status. Customers, some of whom even visit the plant during production, can view the detailed status of their order – down to the last five bags. “This level of information gives ASI's customers reassurance and confirms the quality of their product,” said Michael Blechman, president, ACC.

Pavlik said the Rockwell Automation software has already helped reduce downtime, and they are identifying opportunities to leverage new data for better decision making.

“The life sciences and healthcare industries are constantly evolving, and we evolved with them,” Pavlik said. “Our new state-of-the-art reporting capabilities give our customers the confidence they need to fully invest in single-use devices.”

Published August 1, 2014