Today’s seed manufacturers are challenged to deliver product to meet increased consumer demand while offering the flexibility to facilitate customised packaging to meet specific requirements regarding quantity and seed type. David Hart, CEO at Dematec Automation, knew that the Rockwell Automation’s tightly Integrated Architecture solution was ideal for this application.

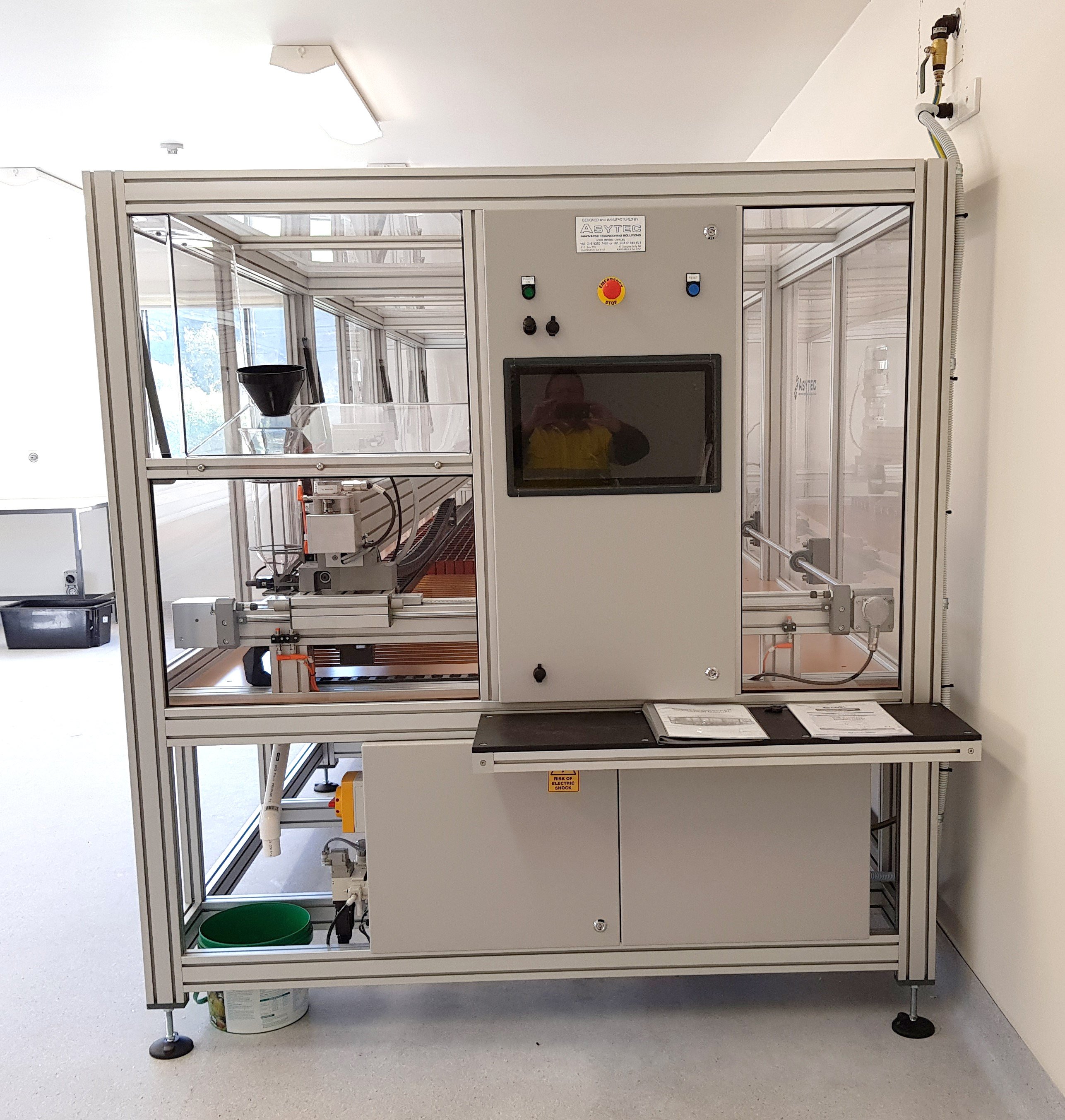

Operator safety is of paramount importance and the Rockwell Automation programmable safety platform enabled PLd/SIL2 Cat 3 certification to be achieved without adversely impacting on machine productivity. “The new seed packing machine was designed to automatically pack seeds of many volumes into plastic magazines, minimizing the requirement for manual handling. Therefore, the control and automation of the machine was critical to its operational success,” explained Hart.

At the core of the machine is an Allen-Bradley® control suite from Rockwell Automation operating over an Ethernet network. Primary control is delivered by the CompactLogix™ programmable automation controller with secondary control and safety provided by Micro800™ controllers. Flexible motor control was delivered by PowerFlex® 525 variable speed drives with Safe Torque-off. The PowerFlex drives provided seamless integration with the Logix environment.

“In addition to the integration and safety features provided by the solution, the flexibility of these products in the machine design helped to reduce engineering time by nearly 20 percent which is an important consideration in any OEM application,” explained Tim Bubb, managing director, Dematec Automation.