Recommended For You

In the food packaging industry, speed and sanitation are critical. But as food trends evolve worldwide, flexibility is becoming increasingly important. More niche and local products are making their way to store shelves. And demand for new sources of protein is changing global diets. Drake, a leading supplier of loading systems for cylindrical food products including sausage and cheese sticks, is positioned to meet the demands of this new environment. Long recognized for its high-speed 1,800 pieces per minute (ppm) equipment, the company recently introduced a loader designed for 200 to 600 ppm – and optimal flexibility.

Drake is headquartered in Waynesboro, Virginia, and is a brand of The Middleby Corporation. The company enjoys a 90 percent share of the frankfurter loading market in the United States, and captures more than 80 percent of new sales in the Western Hemisphere. “Our new LS-600R autoloader is ideal for mid-sized packaging lines,” said George Reed, vice president of engineering and operations, Drake. “It features stainless steel, open frame design – and is an excellent option for lower volume specialty sausage producers or operations that are transitioning from a hand operation to an automatic system.”

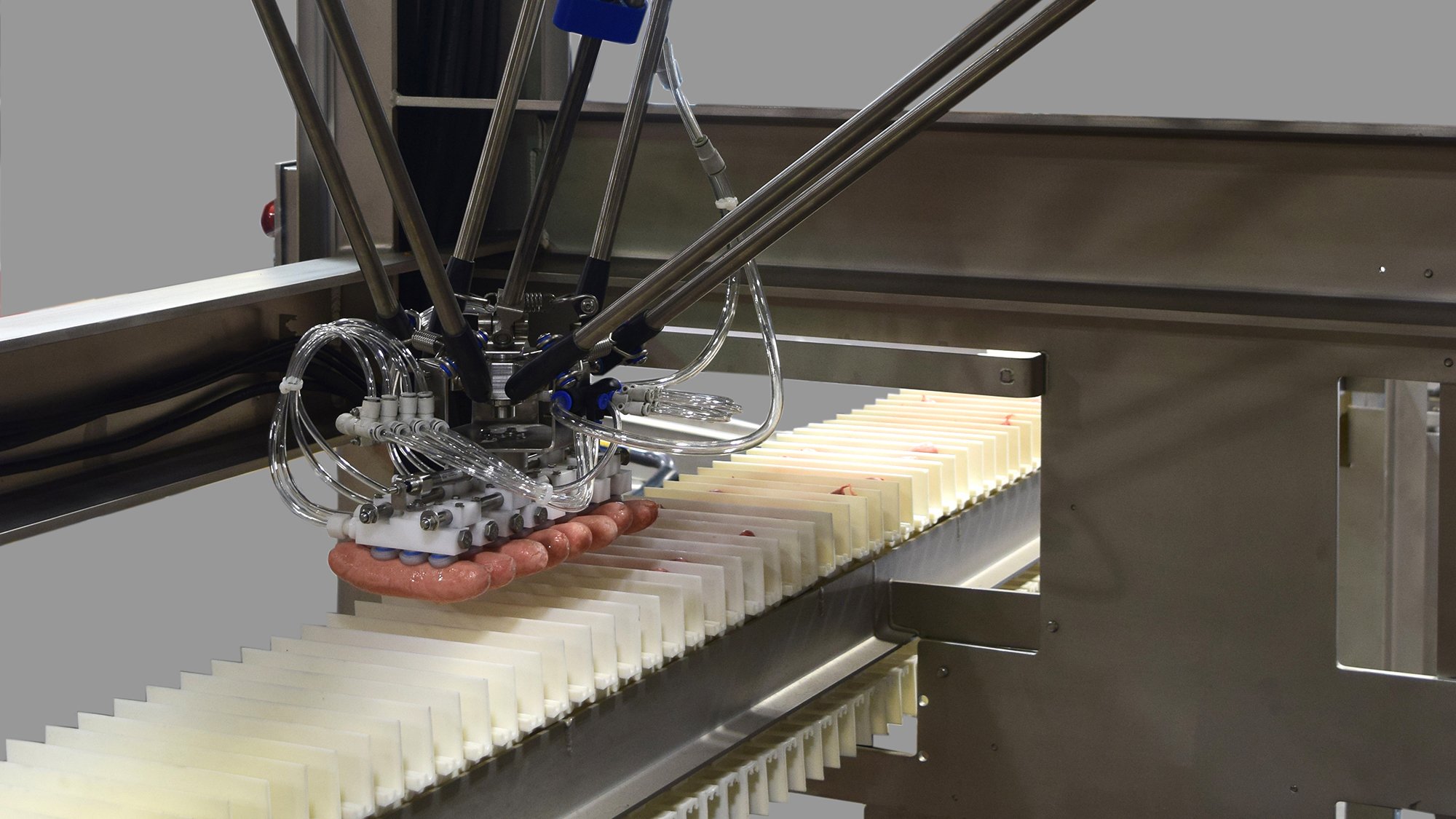

Like the company's other loaders, the LS-600R collates and readies the processed product for final packaging. Typically, the formed and usually cooked product enters a loader's hopper in random fashion. Through a patented sorting mechanism, the machine “unscrambles” the product, places it into pack patterns, and finally transfers it to a horizontal form-fill-seal (HFFS) machine. What makes the LS-600R autoloader unique is its robotic loading head.

“This is the first loader of its type that uses a robotic end effector to pick and place the product into the packaging pockets,” Reed said. “Robotic technology enables us to deliver a flexible solution – in a smaller footprint.” The FANUC robot arm tracks with a moving infeed conveyor and uses vacuum technology to pick the correct number of sausages. As the robot moves toward the pocket, the end effector groups and separates the franks prior to placing them. FANUC is a Rockwell Automation Encompass™ Product Partner. “While our mechanical loading heads offer higher speed, this robotic option enables rapid, tool-less changeover,” said Keith Hopkins, senior control systems engineer, Drake. “Through the machine's operator interface, users can change from one product to another in a matter of minutes.” The loader's Rockwell Automation control and information system features an Allen-Bradley® CompactLogix™ programmable automation controller to manage machine and robotic functionality. Allen-Bradley PowerFlex® 525 AC drives control the infeed and discharge conveyors.

For machine guarding, the loader utilizes Allen-Bradley Guardmaster® safety relays and Allen-Bradley SensaGuard™ non-contact interlock switches. The system is integrated on an EtherNet/IP™ network and monitored on an Allen-Bradley PanelView™ Plus 6 1000 graphic terminal. The system also includes the Allen-Bradley 9300-ENA network address translation (NAT) device. “This device has streamlined configuration,” Hopkins explained. “Previously, we would have to get all IP addresses for the system in advance – or configure the machine in the field. Now, end users can access our machine configurations through a Web browser and quickly set-up their own equipment.”

Those packagers transitioning from a manual operation to the new loader can expect impressive results. On a line running 600 ppm, the machine can reduce human intervention by more than 50 percent. As Drake introduces the LS-600R autoloader worldwide, it will continue to rely on Rockwell Automation service and support. “Our customers around the world are familiar with Rockwell Automation quality – and I know I can count on the company's global support,” said Reed. “At the end of the day, that's really why we choose Rockwell Automation. We can invest in one company – and deliver the same solution worldwide.”

For more information, contact: Drake Company, Phone: +1 540.569.4368

Email: sales@drakeloader.com

Published September 1, 2014