Navigating through the complexity of starting a green hydrogen plant can be overwhelming. But you don’t have to do it alone. We understand the challenges of designing, building and optimizing your green hydrogen production facility. With a data-driven approach and an expansive PartnerNetwork™, we can position you for long-term growth to both scale and maintain your green hydrogen production facilities. Our critical solutions like cybersecurity, interoperability, connectivity and lifecycle services can speed time to market. We’ll help you build the foundation to support long-term green hydrogen production and lower maintenance costs.

World Hydrogen Leaders Intelligence Report

With so many projects being announced daily, the clean hydrogen era is upon us. Read how hydrogen producers can overcome industry barriers in this World Hydrogen Leaders Report brought to you by Rockwell Automation.

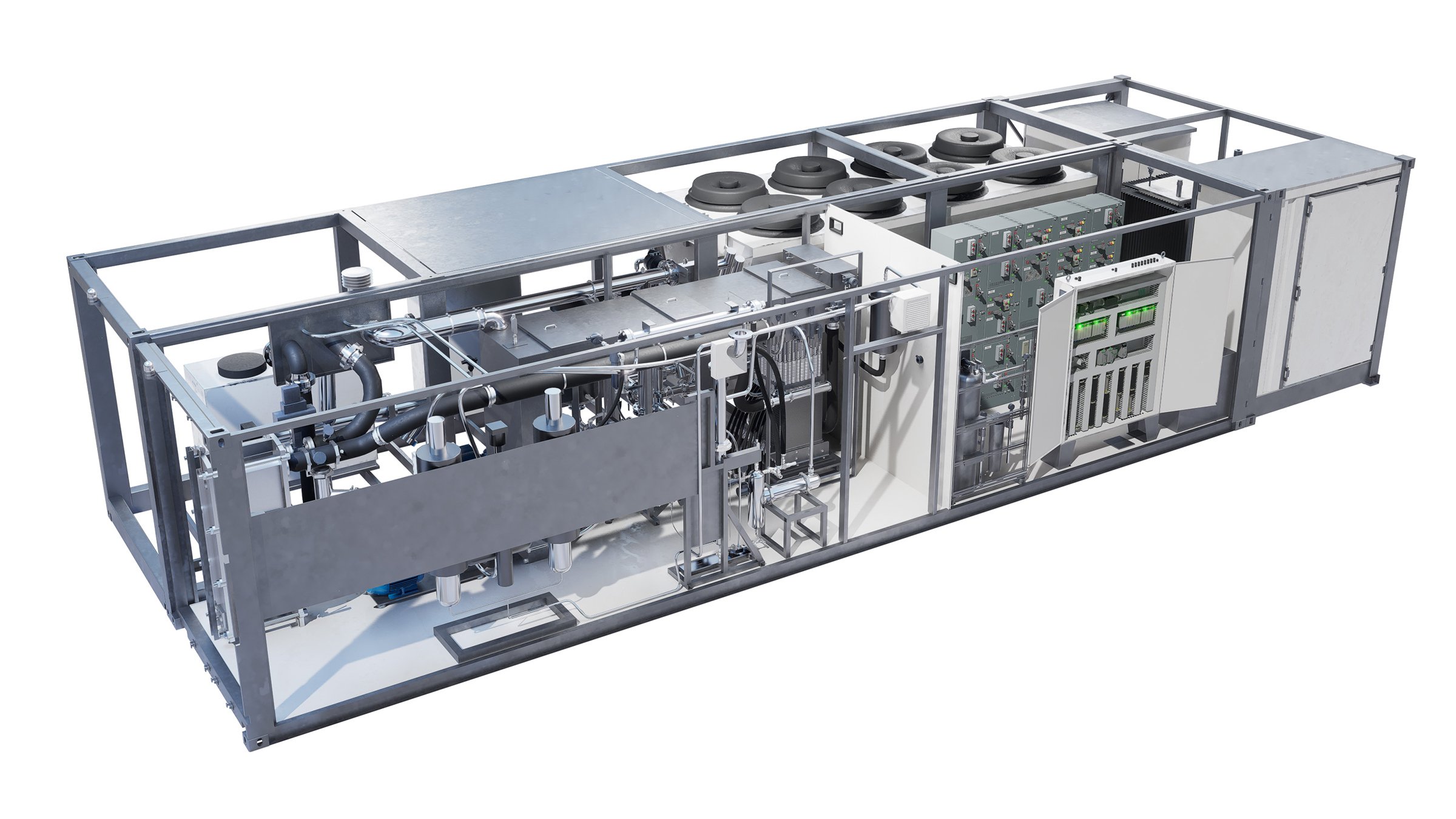

Explore our Green Hydrogen Production Solutions

Discover how Rockwell Automation can help optimize your green hydrogen operations by providing tailored solutions and expert consultancy services. We understand the application challenges facing green hydrogen producers, and our comprehensive digital solutions are designed to address these challenges effectively. Additionally, our team of experts will work closely with you to design and optimize your production processes, helping you gain a competitive edge in the market.

Your Green Hydrogen Production Equipment Deserves a Dedicated Partner

Ensure Safe Operations

Build and scale production of hydrogen generation safely.

Achieve Seamless Integration

Experience a strong digital foundation and global lifecycle support.

Realize Efficient Repeatability

Design and optimize cost effective hydrogen generation systems.

Ways to Ramp Up Your Green Hydrogen Production

Whether you’re starting from scratch or retrofitting a brownfield facility, a strong foundation is needed to build a profitable green hydrogen facility. But, once you’ve laid the groundwork, there are some keyways to optimize your hydrogen operations. Data and a digital-first strategy play an important part.

Green Hydrogen Production Business Challenges

SUCCESSFULLY SCALE PROUCTION QUICKLY

COST-EFFECTIVE SOLUTIONS

SUPPORT ACROSS THE LIFECYCLE (BUILD, SCALE, MAINTAIN AND EXPAND)

SUPPORT SAFETY STANDARDS AND REQUIREMENTS

FUTURE PROOF

Digital Engineering

Get it right from the start and find out which system configuration will optimize the best return for your blue or green hydrogen project.

Process and Power Management

Process and power are the soul of any H2 production. They ensure an optimum, reliable and safer operation.

Smart Instrumentation

Accurate instrumentation ensures that all the H2 production processes are being monitored constantly and consistently.

Smart Analytics

Visibility to ensure efficient production.

Energy Intelligence

Energy management systems (EMS) that couple hydrogen production with renewable generation.

Connected Worker

There is a growing need for identification of the skills and knowledge required by workers undertaking hydrogen related activities.

Discover What Our LifecycleIQ Services Can Do for Your Hydrogen Production Plant

Accelerate Business Growth

Innovation helps you work faster, smarter and with greater agility at every lifecycle stage

Achieve Workforce Excellence

Securely connect people, processes, and technologies

Improve Productivity

Continuously improve performance and production through data-driven decision making

Manage Risk

Meet regulatory compliance and quality standards while protecting people and processes

Drive Sustainability

What You Need to Know About Green Hydrogen Production

Hydrogen is the most abundant chemical element on earth. Despite being present in around 75% of matter, it is never found alone but rather bonded to other chemical elements such as oxygen.

Hydrogen has long been used for a wide range of purposes, including as a fuel source, and across several industries, such as chemical manufacturing and metallurgy. However, since hydrogen cannot be isolated in its purest form directly from nature, it must be done manually.

Historically, this process has produced what is known as grey hydrogen, which isolates hydrogen from fossil fuels. Although this method creates cheap to produce hydrogen, the isolation process emits a large amount of CO2 into the atmosphere. To combat this, many hydrogen producers are turning to a renewable hydrogen production source known as green hydrogen.

What is Green Hydrogen Production?

Green hydrogen production refers to the process of isolating hydrogen atoms through the electrolysis of water. Green hydrogen production also uses renewable energy to drive the process. Therefore, green hydrogen production eliminates the release of polluting emissions into the atmosphere.

How is Green Hydrogen Achieved?

Green hydrogen is created through the electrolysis of water molecules. This means that water molecules are exposed to electricity so that they are split into hydrogen and oxygen electrodes. Green hydrogen production uses renewable energy sources, such as wind or solar, to generate the electricity used in the electrolysis process.

The isolated hydrogen electrodes are then stored in specialized tanks until needed. To turn the hydrogen electrodes into energy, they are transferred into fuel cells where they bind with oxygen from the air, generating electricity with the only byproduct being water.

Benefits of Green Hydrogen Production

Because green hydrogen production reduces the amount of pollutants emitted into the atmosphere throughout the entire process, it offers a wide range of environmental benefits. Some key benefits of green hydrogen production include:

- It’s a clean, renewable energy – green hydrogen does not emit polluting gases during combustion or production.

- It’s storable – hydrogen is easy to store, which means it is able to be used for a wide variety of purposes.

- It’s versatile – green hydrogen can be transformed into electricity or synthetic gas for commercial and industrial purposes.