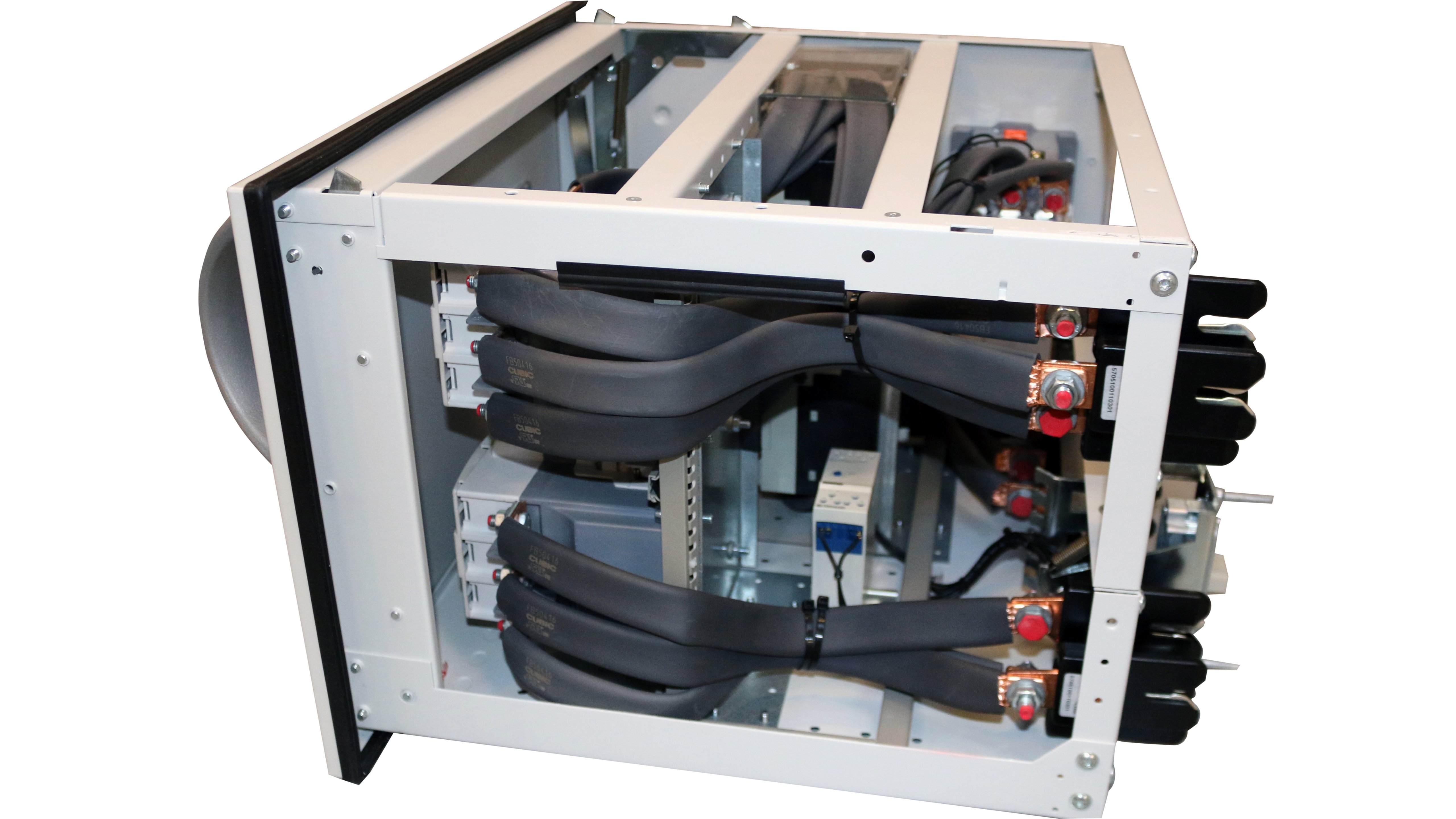

A Cu-flex flexible copper busbar is made of copper wires that are woven into a flexible busbar. Using a proprietary technique, the ends of the busbar are forged into a solid unit. The insulated and flexible busbar provides timesaving and maintenance-free connection contact surfaces for motor control centers, switchboards or industrial control panels.

- Overview

- Documentation

Overview

A Flexible Busbar Eliminates Custom Fabrication

Flexibility is vital when building solutions for today’s ever-changing industrial needs.

The Cu-flex busbars are supplied ready to use. The flexible woven copper busbar is easy to install for new build units or for modifying existing installations. And there’s no time lost on shortening or stripping wires, making holes or complicated bends.

Cu-flex Busbar Advantages

When safety, secure component fittings and flexible busbar solutions are a priority, the time-saving Cu-flex busbars are a must.

Panel builders appreciate the simplicity, functionality and advantages:

- Flexible woven coil easily conforms to meet contact surfaces

- Rated current at 30 °C, up to 1040 A

- Available in lengths 160…1120 mm (6.3…44 in.)

- Up to 1000V

Insulated Busbar with Minimum Maintenance

A Cu-flex flexible busbar is made of copper wires that are woven to create a flexible electrical connection solution. This proprietary manufacturing technique forges the ends of the busbar into a solid unit, making a maintenance-free contact surface and connection.

- Cu-flex busbars feature a flame retardant, reinforced insulated covering

- Busbars are available in a range of lengths and delivered ready for use

- No shortening, stripping or making holes for fitting are required

- Time-saving installation

Cu-flex busbars have been tested and approved under various circumstances by DEKRA and DNV. In addition, Cu-flex is UL67 recognized in the Component - Panelboard and Switchboard Accessories category.

Additional Applications for Flexible Busbars

Due to their versatile properties, Cu-flex busbars have applications in many industries. The flexibility, high electrical conductivity and durability make it an ideal solution where reliable electrical connections and current-carrying capabilities are required.

- Electrical Connections: Cu-flex busbars provide a reliable and low-resistance connection between components, such as transformers, circuit breakers and busbars. They are particularly useful where vibrations, thermal expansion or movement could cause rigid connections to fail. Cu-flex busbars also offer flexibility to accommodate changes or additions to the systems

- Power Distribution: The busbars can be used to connect large electrical equipment, such as generators and substations

- Automotive Industry: Cu-flex busbars can be used for grounding and connecting various electrical components

- Power Electronics: In power electronics devices like inverters and rectifiers, Cu-flex busbars can be used to connect semiconductor devices, capacitors and other components

- Renewable Energy: Wind turbines and solar inverters can benefit from the flexible copper bars to interconnect components and carry high currents generated by renewable energy sources

- Aerospace and Aviation: The busbars can be used in aircraft wiring and electrical systems where weight savings and flexibility are essential

- Industrial Machinery: Flexible copper bars can be used for power transmission, control systems and motor connections

- Battery Systems: In large-scale energy storage systems or electric vehicles, Cu-flex busbars can be used to connect battery cells or modules

You may also be interested in