One Platform, More Control

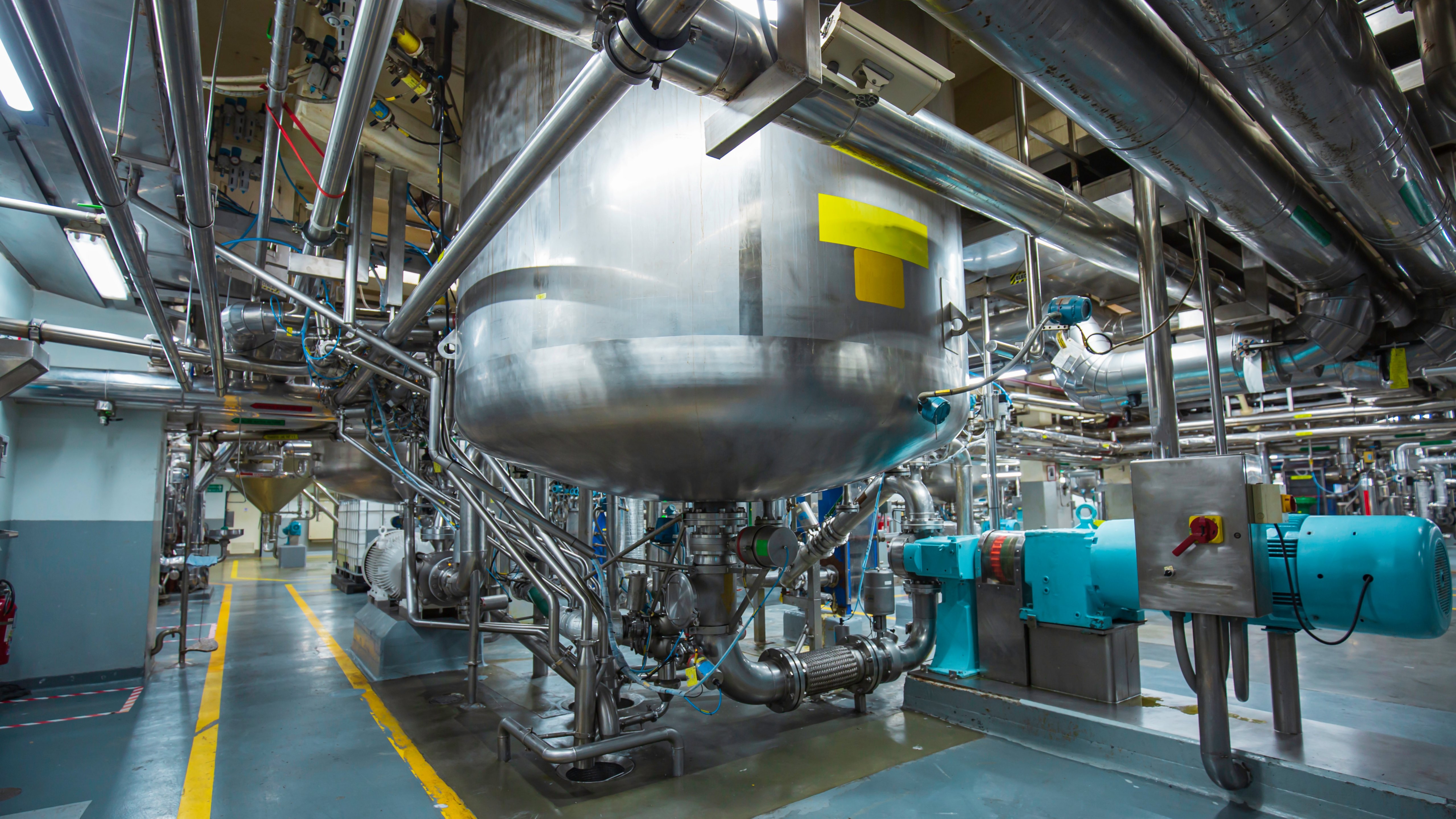

Chemical manufacturers can no longer depend on disparate systems that operate on separate platforms, as this approach hinders progress and introduces risks. Operational elements such as the basic process control system (BPCS), safety instrumented systems (SIS), variable frequency drives (VFD), motor control centers (MCCs), instrumentation, control software and energy management programs must work together. An integrated architecture connects the entire enterprise and allows for access to real-time data that has automated or actionable responses.

Operating a single platform with a modern process control system (e.g., Rockwell Automation’s PlantPAx®), smart technologies and processes has numerous advantages that help:

- Mitigate risks, such as the ability to:

- Identify, monitor and enhance awareness of environmental or safety risks

- Develop broad-based security measures for cyber threats and related vulnerabilities; a single platform strategy provides real-time asset inventory, vulnerability management and risk remediation

- Increase reliability to reduce unplanned downtime or outages

- Create flexible and agile production operations that use real-time data to improve productivity, quality, efficiencies and speed to market for ever-changing product requirements

- Simulate new process scenarios and optimize response to consumer and market changes

- Adapt manufacturing operations to achieve environmental regulation and safety standards

- Develop continuous improvement and sustainability strategies for regulatory compliance and the environment

- Provide automated warnings based on sets of conditions that point to predictive maintenance needs

For more efficient operations, manufacturers are increasingly choosing to connect process and power, which typically function on separate systems. Using today’s smart technologies, chemical manufacturers can integrate power and process systems on one platform, which delivers cross-functional visibility and interactive communication, simplifying the environment for operators in a Total Connected Chemical Plant (TCCP).

By using one platform and the right technology, key personnel can gain a comprehensive view of the entire enterprise. This unified approach provides access to real-time data that helps manage risk in various operational processes, such as asset performance management, energy management, process management, production analytics, safety, and cybersecurity. These insights help identify hidden anomalies and optimize efficiencies across the facility, ultimately reducing upfront capital costs and lowering the total cost of ownership (TCO).

In addition, simplifying hardware operations and software configurations help chemical companies tackle workforce challenges. By capturing specialized knowledge, companies provide workers with insights that promote operational consistency. Plant operators can focus on a single system, providing a modern digital view of the enterprise, which enhances the user experience and improves quality and safety.

Choose the Right Partner

With the right automation solutions partner, chemical manufacturers can take an incremental approach to modernization projects and deliver the desired business outcomes. In doing so, they can build an information enabled enterprise that yields the best return on their automation investment for years to come.

Tapping their extensive knowledge of major automation platforms and systems, as well as system design, simulation and digital twin, an automation solutions partner can answer any questions to remove any uncertainty and doubt from the upfront engineering process, covering the early planning stage – front-end loading (FEL) and front-end engineering design (FEED) – to implementation, installation and startup services to continuous support. Early engagement results in clearer definition of the project scope.

This holistic, fit-for-purpose approach and solution helps identify risks and prioritize results. A trusted partner brings deep domain and technology knowledge, methodologies and standards to digitally transform and optimize operations.

Build a Plant for the Future

Any modernization project is a major investment in time and resources, but aging systems just aren’t sustainable. Chemical manufacturers must reevaluate their systems and processes and be open to an integrated platform with innovative digital technologies that can help enhance operations and provide personnel with the ability to make timely critical data-driven decisions.

An integrated platform will provide a more agile, flexible, and sustainable plant environment that meets the demands and expectations of today’s marketplace. By partnering with an industry knowledgeable team and automation solutions provider, chemical manufacturers can take an incremental approach to modernization. This approach will help them develop a data-driven enterprise with resilient operations that maximize the return on their investments for years to come.