By Paul Gruhn, P.E., ISA Fellow, Global Process Safety Consultant, Rockwell Automation

Editor's Note: This article is adapted from Paul's full white paper, “Is your existing Safety Instrumented System up to current standards?” Visit http://goo.gl/2aHIXA to download this free, comprehensive white paper to learn even more about SISs, standards and how to determine if your systems comply.

Process safety is a major concern to anyone who works in a process facility. An estimated 25,000 facilities covered by the Occupational Safety and Health Administration (OSHA) Process Safety Management of Highly Hazardous Chemicals regulation will most likely have safety instrumented systems (SIS), also known as emergency shutdown systems.

Guidelines and standards for the design and implementation of safety systems have been in place in a variety of industries since the 1990s. Many things change, even standards. However, many other things don't change — or change very little — such as industrial processes that have been running for decades.

So what are you expected to do with safety systems installed prior to current standards? Are previous designs automatically assumed to be acceptable, or must all older systems be ripped out and replaced? We explore this topic.

How can I determine if my existing system is acceptable?

There are two fundamental steps to determine if your existing systems are acceptable:

• Step #1: Identify all safety instrumented functions (SIFs) and determine what level of performance they need to meet — that is, determine the required SIL of each SIF.

• Step #2: Analyze/model/calculate the performance of the actual hardware to see if it will meet the required performance.

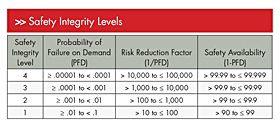

To help address step one, Figure 1 shows the performance requirements for the different SILs. Part 3 of the standard summarizes several different techniques used around the world for determining SIL, including the risk matrix, risk graph and layer of protection analysis (LOPA). It's worth noting a statement made in the introduction that says, “The information provided is not of sufficient detail to implement any of these approaches.”