“For easy integration, reliability and cost effectiveness we used the Rockwell Automation midrange Integrated Architecture® solution on the mill. We chose this because we had a complete set of industry tools to make the Magotteaux Mill sing, including the CompactLogix™, PanelView™ and very soon, the Magotteaux Mill will be using FactoryTalk® Historian. These tools provide the same control power that we would use on a mine site but in a scaled down form for this application,” said John Karageorgos, Managing Director at Manta Controls.

Challenge

- To improve the productivity of mineral processing by developing a solution that monitors and optimises mineral processing in real time

Solutions

The Magotteaux Mill®

- CompactLogix™ provides midrange application control in an easy to use environment

- FactoryTalk® View Studio Machine edition is a versatile HMI application that provides a dedicated and powerful solution for machine-level operator interface devices

- PanelView™ graphic terminal

The Pulp Chemistry Monitor (PCM™)

- CompactLogix provides effective control power for the PCM™

- FactoryTalk View and Historian deliver superior integration and visibility

- MantaCube for high level control functionality

Results

Real time processing plant monitoring

- The PCM monitors the plant in real time to improve productivity and recovery

- Small compact machine for minimal footprint

Connected, integrated system

- Ethernet used as communications backbone for real time monitoring

No interruption to process

- The PCM is installed and operates with no interruption to the current process

Saves costs and the environment

- By reducing the amount of reagents required, the PCM delivers both cost and environmental savings

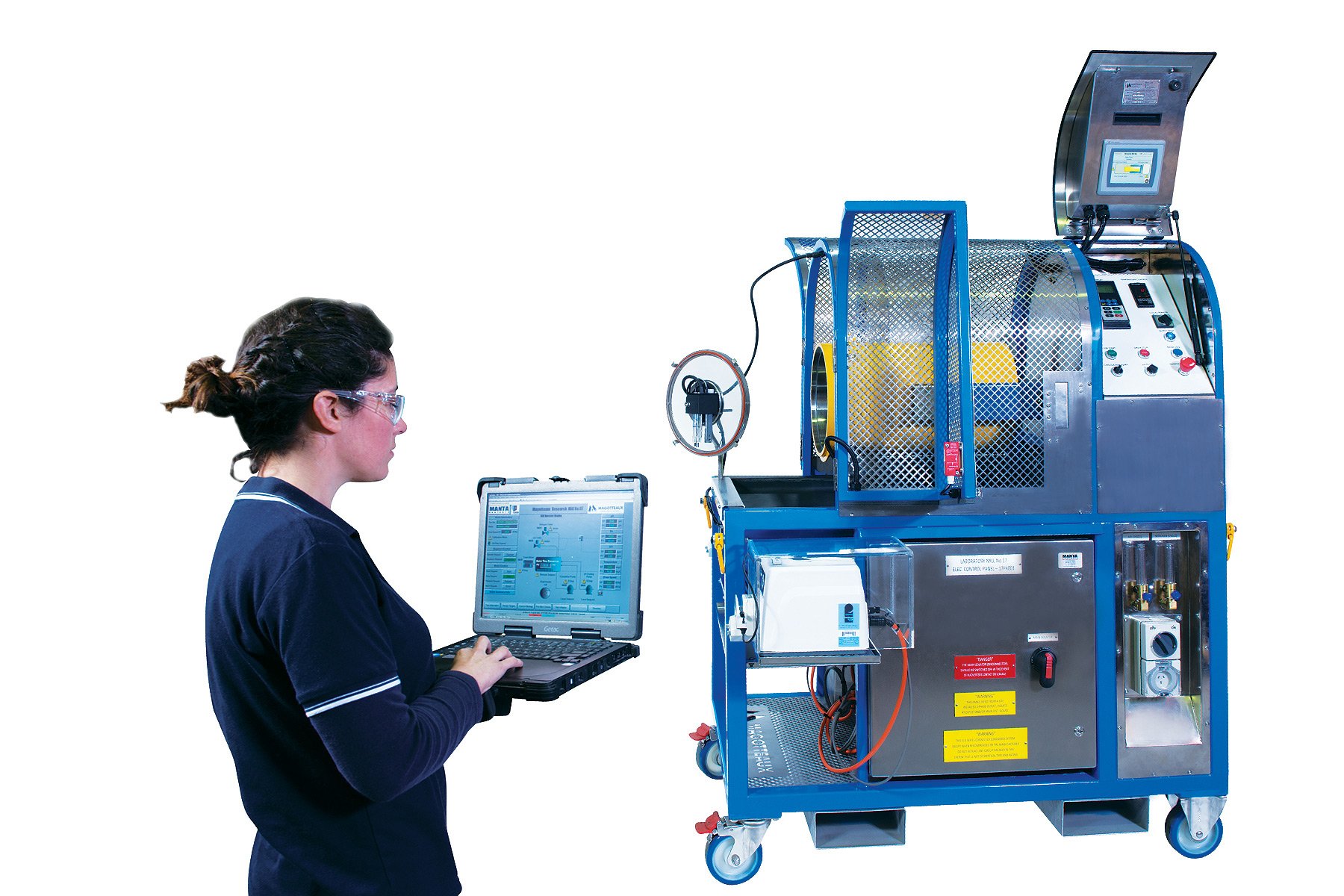

The Magotteaux Mill replicates the plant physical and pulp chemistry properties in a laboratory.

The downturn in commodity prices together with the thinning of high grade resources has emphasised the importance of improving mineral recovery rates and quality for mining operations.

Magotteaux is a global leader in developing process optimisation products and services for high abrasion extraction industries. The company leverages innovative new technologies to help customers improve the quality and quantity of their yields and optimise their total cost of ownership.

Magotteaux is the only supplier offering the full range of grinding media including: cast and forged, low and high chromium, balls/boulpebs/rods and ceramic grinding beads. The company prides itself on delivering superior customer service through their technical knowledge and employs specialised process engineers who recommend the most appropriate media, shape, size and alloy for each unique application.

Magotteaux not only specialises in grinding media, but their holistic approach to the customers’ process (Chemillurgy®) employs a range of innovative patented technologies that assist the operator in real-time monitoring of their process to maximise their metallurgical performance.

Magotteaux designs and manufactures several patented machines for specific industries, with a view to better answer customer needs and optimise their production processes.

The challenge ahead was to deliver a fully automated device, leveraging the latest technologies to help mining companies improve the productivity and quality of their mineral processing facilities. To develop a solution that could both monitor and optimise mineral processing in real time, Magotteaux collaborated with a leading Australian process control company, Manta Controls.

Reliable testing: The Magotteaux Mill® reproduces plant conditions in a lab

Historically, forged steel grinding media was considered to be the best available medium but in certain mining applications there is a significant limitation – corrosion appears when it is exposed to water and sulphide minerals. The corrosion products from the grinding media then coat the surface of the minerals that are to be separated which can depress the flotation and leach recoveries of the minerals, and can lead to the plant using more reagents. In such applications, the use of high-chrome grinding media, which inherently has better abrasion and corrosion resistance, reduces the amount of iron hydroxide released into the system, which can therefore reduce reagent consumption and increase recoveries.

Magotteaux has developed a unique know-how to identify the best suited grinding media for each mineral processing circuit. As the company is the sole supplier of all types of grinding media, it can define and offer the best suited medium along with a tailored reagent scheme to allow for maximised recoveries and costs to stay under control.

Dr Christopher Greet, Manager Minerals Processing Research, at Magotteaux was tasked with visiting various mines around Australia to develop and apply the know-how and show that the use of high chrome media can reduce the wear rate and produce cleaner surface chemistry, which can then reduce reagent consumption and improve valuable mineral recoveries.

According to Greet, “The Magotteaux Mill® was developed to make the chemistry of the product from the lab mill look very much like the chemistry of the plant. It generates a product in the laboratory that has the same physical and pulp chemical properties as an equivalent sample taken from the plant. As such the impact of the choice of the grinding media on the process can be assessed and the best suited solution can be defined.”

The Mill was originally manually operated but to improve the reliability of the system, Magotteaux called on Manta Controls to help automate the mill and therefore improve its reliability and reproducibility.

The PCM provides real time information that helps optimise grade and recovery.

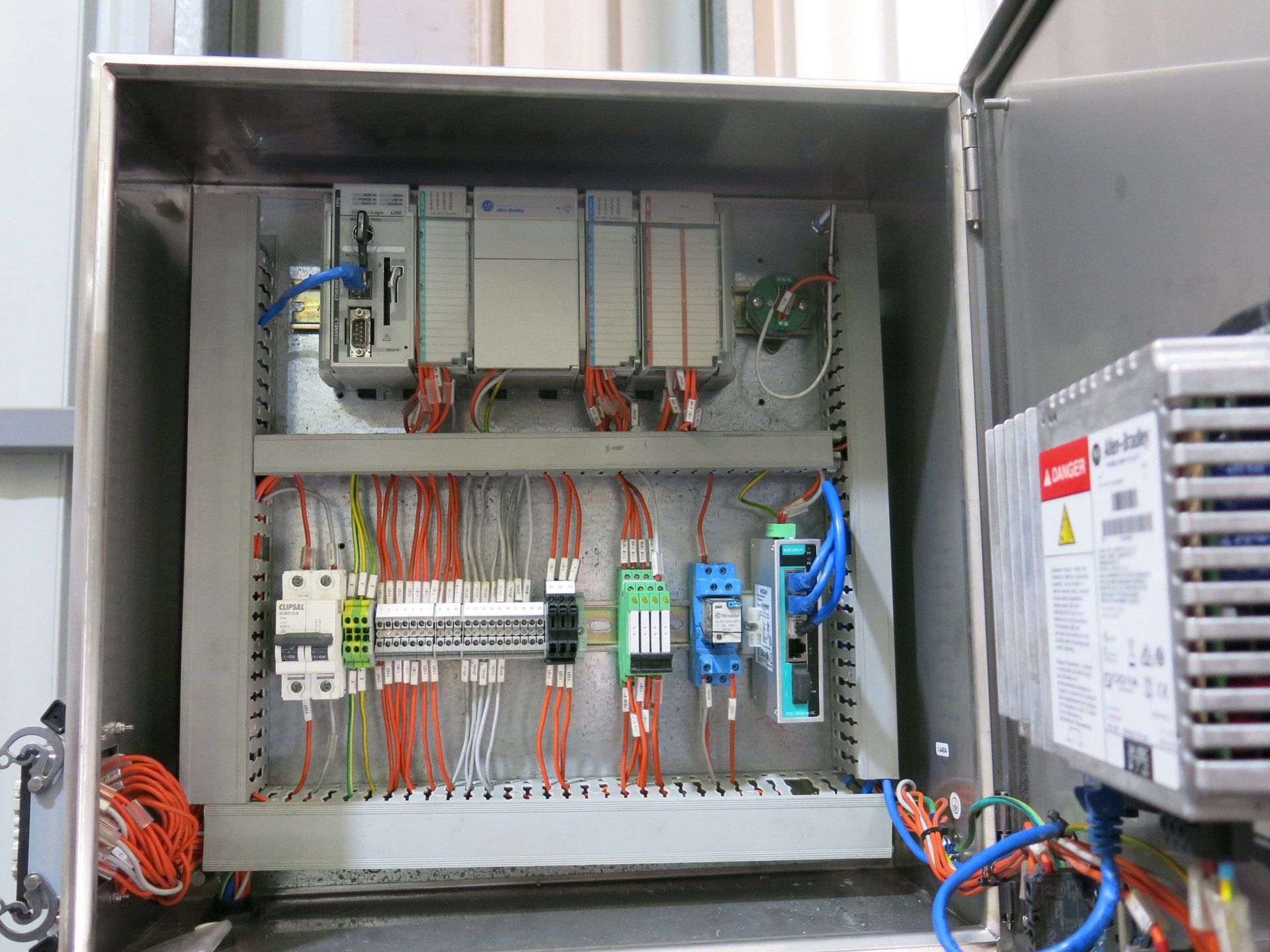

CompactLogix controls both the Magotteaux Mill and PCM, and is capable of running the Manta Cube advanced control system.

“The Magotteaux Mill integrates different devices so there wasn’t anything off the shelf that we could use to get them talking to each other. Manta invested the engineering time on the communications for the mill and it is now extremely robust,” he explained.

CompactLogix provided the control power required for the Mill in a compact and affordable package. It uses the same programming software, network protocol, and information capabilities as all Logix controllers, providing a common development environment for all control disciplines.

The Mill is a very important tool in Magotteaux’s arsenal to show that high chrome is better than forged steel. This led to the development of the Pulp Chemical Monitor (PCM®) that provides the capability to actually start measuring the pulp chemistry online and in real time on a mine site.

The Rockwell Automation midrange Integrated Architecture® solution is used on the Magotteaux Mill for easy integration, reliability and cost effectiveness.

The Pulp Chemical Monitor delivers real time monitoring and optimisation

Optimising plant conditions to improve mineral recoveries is an important priority for mineral processing facilities. By understanding how the chemistry and mineralogy are linked, strategies can be developed to overcome variations, which can result in a plant that runs more smoothly, and therefore increases valuable mineral recoveries.

Understanding the chemistry of the feed also helps reduce running costs because by analysing the chemistry of the feed, the amount of reagents required can be reduced. In addition to the cost benefits, reducing reagents also has positive flow on effects for the environment and sustainability of the system.

The PCM™ was developed to provide an online view of the dynamics of the mineral processing plant. By monitoring the chemistry in real time, the process can be optimised and metallurgical performance improved.

“The ore body is quite variable and the chemistry may change within the hour. In the past we haven’t been able to see these new chemistry variables that Magotteaux have developed online and then make an association with what is changing with the minerals,” said Karageorgos.

“If the mineral recovery or grade drops you need to understand the dynamics of the chemistry. In the past you had to take a sample, send it to a lab for testing and wait days or weeks for answers but with PCM we can see what is happening within minutes,” he said.

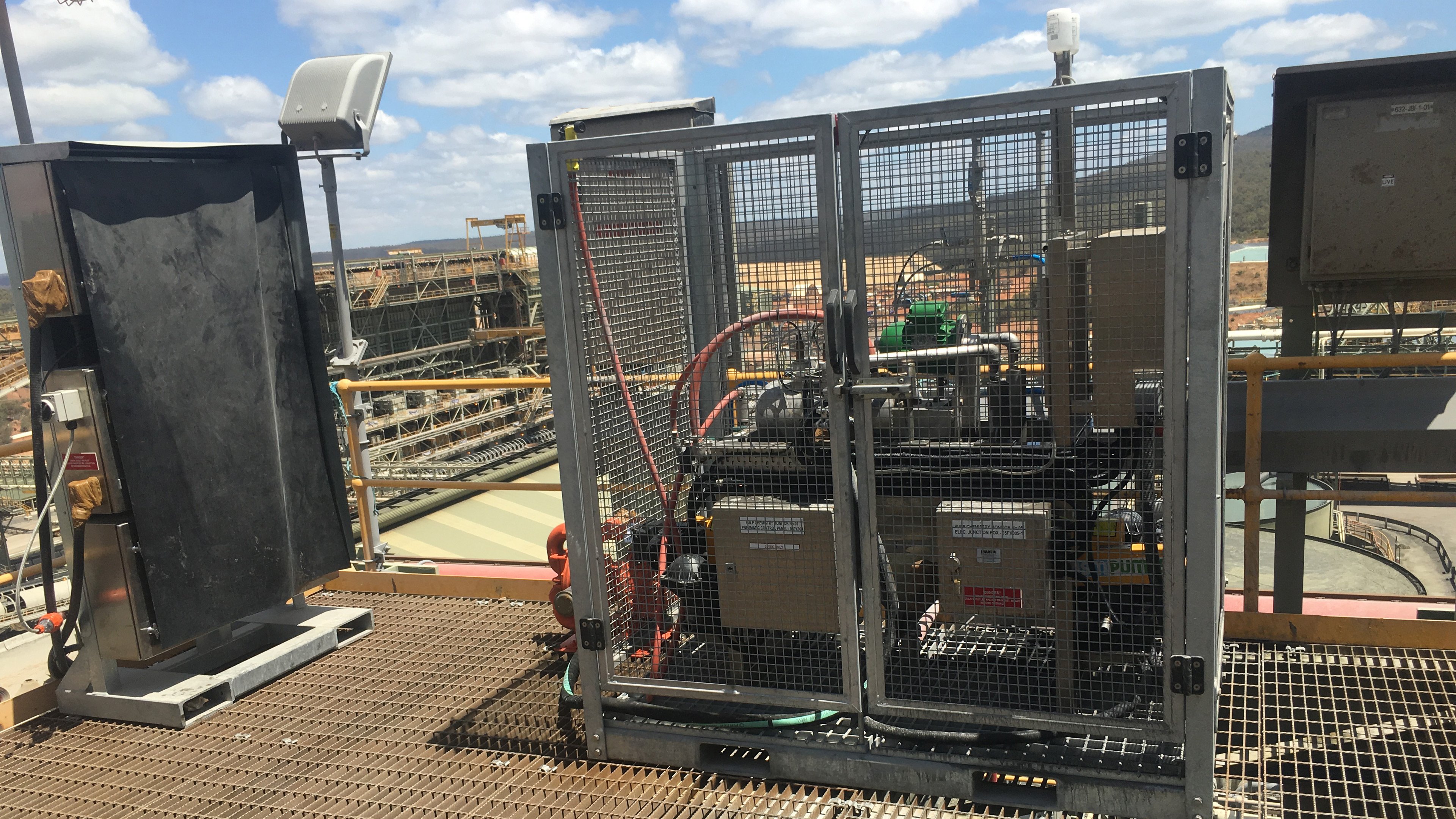

The PCM has been tried and tested in mineral processing plants for the past few years. Manta invested the time in engineering the solution to be robust enough to cope with the harsh environments of the processing plants. It can cope with being exposed to slurries and salts as well as the weather elements.

Complete control technology

Manta Controls specialises in implementing the best possible control strategy for a particular piece of equipment or area of the plant. To achieve this for PCM, Manta developed a unique Manta Cube system that utilises advanced control fundamentals.

The ability of PCM to provide real time information that helps optimise mineral quality and recovery is the result of the complete integration of communication and high-level control functions. To achieve this, Manta Controls leveraged the inherent flexibility and scalability of the Rockwell Automation Integrated Architecture platform.

“We decided to choose the Rockwell Automation control system because it’s one of the most widely used systems in the world. This makes installation of PCM easy in any system whether it is a Rockwell Automation site or not, communication is easy either way. Additionally, they provide a lot of knowledge and support about how to optimise the system and the latest new developments,” said Karageorgos.

Like the Magotteaux Mill, PCM is also controlled by CompactLogix, which has all the functionality of ControlLogix® and is also compatible with the advanced control signals generated by the Manta Cube. FactoryTalk View and Historian provide robust and reliable functionality in a single software package. The Historian is used to track and log process data on the machine and is easily integrated with CompactLogix.

According to Jonathan Footman, solutions architect at Rockwell Automation, “Integrated Architecture was the most appropriate choice for this application because it is a scalable solution that offers the convergence of control and information systems, delivering both real-time and historical data and reduced engineering time.”

Australian innovation, global application

Leveraging new technologies to develop innovative products that can help mining companies improve productivity and profitability remains key to meeting future challenges. Both the Magotteaux Mill and PCM provide a means that can help improve productivity through improved mineral recovery and quality both in Australian mines and around the world.

Both machines are manufactured in Adelaide, South Australia to Australian machine standards. They are exported globally and comply with relevant safety standards. By incorporating technologies with inherent flexibility and scalability, the machines can be integrating into a range of mineral processing facilities.

“We enjoy a mutually beneficial and productive relationship with Magotteaux. At Manta, we ensure that the machines deliver all the parameters required for effective process control and Magotteaux makes sure that the units work well in terms of improving mineral recovery,” said Karageorgos.

Company background

Rockwell Automation Australia and Rockwell Automation New Zealand are subsidiaries of Rockwell Automation, Inc.—a leading global provider of industrial automation and information solutions that helps manufacturers achieve a competitive advantage in their businesses. The company brings together leading global brands in industrial automation which include Allen-Bradley® controls and services and Rockwell Software® factory management software. Its broad product mix includes control logic systems, sensors, human-machine interfaces, drive controllers, power devices, and software.

Rockwell Automation, Inc. (NYSE:ROK), the world’s largest company dedicated to industrial automation and information, makes its customers more productive and the world more sustainable. Headquartered in Milwaukee, Wis., Rockwell Automation employs approximately 22,000 people serving customers in more than 80 countries.

Allen-Bradley, ControlLogix, CompactLogix, FactoryTalk, Integrated Architecture, PanelView, and Rockwell Software are trademarks of Rockwell Automation, Inc.

Magotteaux Mill and the Pulp Chemistry Monitor are trademarks of Magotteaux.

Media contact:

Christine Filippis

Teraze Communications

61 3 8391 0701

christine@teraze.com.au

Published July 31, 2016

Recommended For You