Food and pharmaceutical makers can better protect the integrity of their products using new hygienic industrial control hardware from Rockwell Automation. The new Allen-Bradley Kinetix VPH hygienic servo motors and a new stainless-steel version of the Allen-Bradley PanelView Plus 7 graphic terminal both help minimize contamination during production and ease compliance.

The stainless-steel PanelView terminal can be used on a machine in a “splash” or contaminant zone without the need to be covered or isolated. This helps protect product quality and simplifies the cleaning processes, while removing obstructions to the human machine interface (HMI), so operators can better monitor production.

“In food and beverage manufacturing, demand for more product varieties is creating a need for smaller, more flexible machines with the HMI located in close proximity to the process,” said Dan Henneberry, business manager, Rockwell Automation. “The stainless-steel version of our PanelView Plus 7 terminal stands up to the rigors of contamination and cleaning to make this possible.”

The product is the industry’s first general-purpose HMI terminal that is certified by the National Sanitation Foundation (NSF). It has an ingress-protection rating of IP69K to support high-pressure, high-temperature chemical wash downs. It also uses a food-grade silicone gasket with a distinct blue color to help production workers notice if it’s been damaged and needs to be replaced.

The new Kinetix VPH hygienic servo motors can improve machine reliability while enhancing consumer safety by meeting stringent hygienic standards. The hygienic design – including high-grade stainless-steel housing and a smooth surface – can withstand wash downs and reduce the risk of contamination.

“Some servo motors can fail just weeks after they’re exposed to cleaning and sanitizing agents,” said Wendy Du, product manager, Rockwell Automation. “Alternatively, motors can be covered and protected during the cleaning process; but that creates a lengthier cleaning process and can introduce contamination risks. Our new hygienic servo motors make cleaning and sanitization easier and more efficient to help reduce machine downtime and improve overall equipment effectiveness.”

The servo motors are designed per the EHEDG and 3-A sanitary standards and are IP69K rated and NSF certified. They seamlessly integrate with the Allen-Bradley Kinetix 5500 and 5700 servo drive platform, using single-cable technology to help optimize a machine’s speed and accuracy. And they’re available in a range of sizes and options to help meet a variety of application needs in food and pharmaceutical production.

Safety I/O Modules for Smarter Machines

Companies that adopt a holistic approach to machine safety achieve significantly higher overall equipment effectiveness. The latest Allen-Bradley FLEX 5000 safety I/O module delivers a flexible and reliable distributed I/O solution, allowing you to choose your I/O to meet your operational needs.

FLEX 5000 I/O enhances communication with 1Gb EtherNet/IP connectivity offering higher speed and increased bandwidth to deliver increased amounts of data back to the controller. This helps future-proof control systems for a Connected Enterprise. During production, the modules can reduce costly and unplanned downtime, especially in continuous process control applications. Removal and insertion under power (RIUP) allows technicians to replace existing I/O, and an online change capability allows configuration of new I/O, both while the system continues to run.

Flexibility is provided through multiple network architectures and topology options in addition to a wide range of standard and safety I/O modules. These modules are ideal for applications that require fixed field-wiring terminations and either vertical or horizontal mounting.

The distributed I/O modules can operate in extreme environments and be used directly, connecting to copper and fiber networks. The FLEX 5000 platform provides distributed safety I/O for the Compact GuardLogix 5380 and GuardLogix 5580 controllers.

The I/O modules are TÜV certified for use in safety applications up to SIL 3 and PLe, Cat. 4. In addition, the FLEX 5000 I/O modules are selectable with conformal coating options for added protection against environmental stresses.

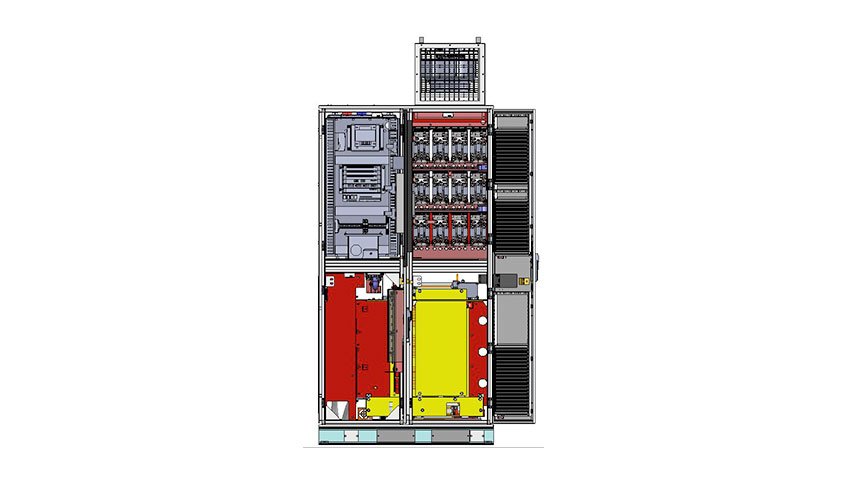

ControlLogix CIP Safety I/O Modules

The Allen-Bradley ControlLogix CIP Safety I/O modules provide local safety I/O for the GuardLogix 5580 controllers in larger applications that require a high-density I/O solution. Using these in-chassis modules simplifies configuration and reduces panel space by eliminating the need for an adapter. The module can be used in local chassis of a ControlLogix controller or in a chassis linked to a ControlLogix controller across ControlNet or EtherNet/IP networks. These modules can also be used for distributed safety I/O.

The ControlLogix CIP Safety module provides a full range of digital, diagnostic digital, analog, motion control, specialty I/O, and compute modules to meet your application needs. Offering functional safety rated up to and including SIL3 and PLe, these modules also support CIP safety bridging and routing functionality. Providing enhanced reaction time, the ControlLogix CIP Safety I/O modules helps protect your personnel and equipment assets.

Compact 5000 Safety I/O Modules

The Allen-Bradley Compact 5000 safety I/O modules provide local and distributed safety I/O for the Compact GuardLogix 5380 safety controller and distributed safety I/O for the GuardLogix 5580 safety controller. The modules offer faster safety reaction times to help designers lower their costs and create smaller and simpler machines. They also provide additional diagnostics to help users more easily identify faults.

Using EtherNet/IP for increased overall productivity, machine builders are empowered to solve their customers’ current and future problems through a unified architecture. The system continues to expand performance capabilities within the platform.

The Compact 5000 safety I/O modules are rated up to SIL3/PLe and provide separate system power for better isolation and built-in power input with field power to I/O modules.

Flexible Servo Control and Accurate Positioning

The Bulletin VPAR electric cylinders provide an integrated solution with dynamic, precise response for a wide range of linear motion applications. Providing seamless connectivity to Kinetix 5500 and 5700 drives, these cylinders use RSLogix 5000 software to extend and retract with highly repeatable positioning, velocity, and force.

Simplifying wiring, the cylinders connect with a single cable connection and are suitable for either axial or parallel mounting. The Bulletin VPAR electric cylinders are designed to simplify your assembly and reduce mechanical design engineering, wiring and commissioning time.

Latest Studio 5000 Software Reduces Machine Design Time, Enhances Industrial Security

The latest release of the Studio 5000 integrated development environment from Rockwell Automation can help get smart machines to market faster with enhanced security. The software includes new digital design capabilities to reduce machine design, testing and commissioning times. It also introduces CIP Security support to bring industry-proven security technologies into the automation space.

To accelerate design projects, the Studio 5000 Logix Designer application now uses an AutomationML open data exchange. This allows the application to exchange data with engineering tools, such as EPLAN Electric P8. Now, engineers can design their system once and import that design data between tools, saving hours of rewriting and remapping work per project.

Also, a new Simulation Interface product uses the Functional Mock-Up Interface (FMI) standard to allow data exchange with modeling software, such as MATLAB and Simulink. Engineers can use this to virtually test machines and resolve issues before commissioning, potentially reducing on-site delivery times from weeks to days.

The latest Studio 5000 software allows companies to use CIP Security to better protect their industrial communications with authenticity, integrity and confidentiality. The FactoryTalk Policy Manager tool allows administrators to centrally manage secure communications policies within the Studio 5000 environment in compatible hardware. This allows a CIP securable device to defend itself against a network or communications attack.

ThinManager Expanded for Global Use

ThinManager version 11 adds features that allow end users to increase their productivity, visualization, security and mobility