Expert #2: - Nope, that’s not how you do it…-

Operator: - But expert #1 told me this was the right way. -

Expert #2: - Well, the way I do it also works. Besides, Expert #1 left a week ago, do it my way if you please. –Operator: - OK… but which one is the right way?

Expert #2: - Whatever you feel like doing is fine…-

Operator: - Right…-

Accelerating Workforce Training

Which one is the right way, indeed? When dealing with a new workforce, accelerating their training is the top priority, and having several options to solve a problem can be confusing, especially if it’s your first (or second or third) time. The more we ignore this issue the bigger the skills gap gets, impacting directly on new hires and unfilled positions. According to Deloitte[1], this translates to an estimated 2.4 million positions that may remain unfilled.

Obstacles to "over the shoulder training"

Now, don’t get me wrong, the “over the shoulder” approach is effective, but there are some obstacles that we need to avoid, for example:

- Aging and retiring workforce: “There are a high percentage of workers eligible to retire in manufacturing in the next 1-2 years (58%), as well as the next 3-5 years (52%).” (SHRM)

- Ineffective traditional training methods: “Without consistent repetition and reinforcement of work-related concepts, workers will forget 50 percent of information within one hour, 70 percent within 24 hours, and 90 percent over a week.” (Axonify)

- Negative perceptions of industrial work: “In a recent poll, 61% of teenagers perceived that a manufacturing career entailed a "dirty, dangerous place that requires little thinking or skill from its workers and offers a minimal opportunity for personal growth or career advancement.” (FMA)

- Current frontline worker information insufficient to needs: “An estimated majority (80%) of the world’s workers do not work at a desk, yet only 1% of the $300B spent annually in software venture capital goes towards technologies for these workers.” (Emergence)

Three types of knowledge

Also, when talking about the knowledge transfer itself, the “over the shoulder” approach tackles three types of knowledge[2]:

- Explicit is the kind of knowledge that can be easily written down or verbalized

- Implicit is the application of detailed knowledge

- Tacit is knowledge gained through unique experiences that are difficult to explain—having a 'feeling' for performing a task

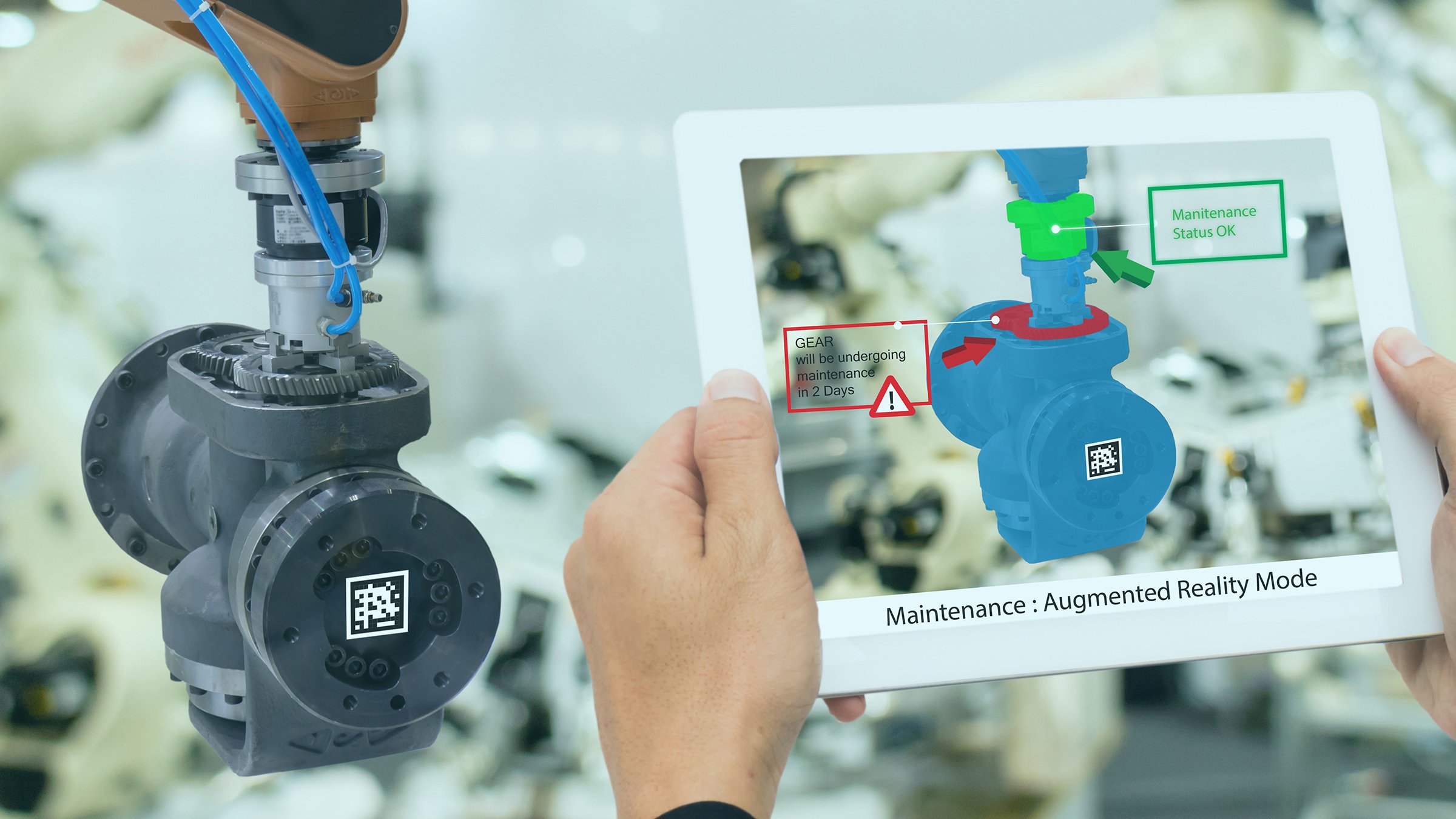

Looking at how the obstacles in the industrial environment and the way we share knowledge intertwine, a tool capable of managing the latter is in order. Augmented Reality can be a great fit through a capture of expertise solution[3].

Empower your workforce with Augmented Reality

If you are thinking about implementing these solutions into your everyday tasks, there are three fundamental capabilities:

- Empower the subject matter expert with a record of all asks, using text, audio images and/or video, addressing the explicit and implicit sides of knowledge capture.

- Empower the operator/worker with the ability to use his hands at the same time he’s looking at the instructions (perhaps through an eyewear device), allowing him to explore the tacit side of knowledge capture. With Augmented Reality, all the relevant data can be in front of the user’s eyes, avoiding distractions, and in a way that is safe.

- And finally, offer a solution that can update and propagate new information into all your team’s devices in real time, without having multiple versions of the same procedure or not being sure if it’s the latest update.

Other features that should be considered are the use of voice commands, the ability of highlighting the spatial surroundings and of course, since we’re sharing the content in real time, a cloud deployment that can be easily reached by all teams.

But what are the benefits? Well, bottom line, you’re considering a tool that’s able to address knowledge management, having the right information for the right people.

With AR, you’re using a tool that can increase the efficiency and productivity of new workers by using state of the art technology that empowers them to follow procedures at their own pace, without the concern of “over the shoulder” training. The impact of using AR as a knowledge transfer solution translates directly into costs, first time fix rates and scrap and rework reduction. The enterprise will have an enabled workforce who can share their knowledge and improve their skills.