“By using Emulate3D to simulate the operations of physical warehouses, we can reduce the gap between virtual and physical environments, effectively enhancing communication efficiency on the business side.’’

Applications of Emulate3D in warehouse logistics include:

- Initial planning

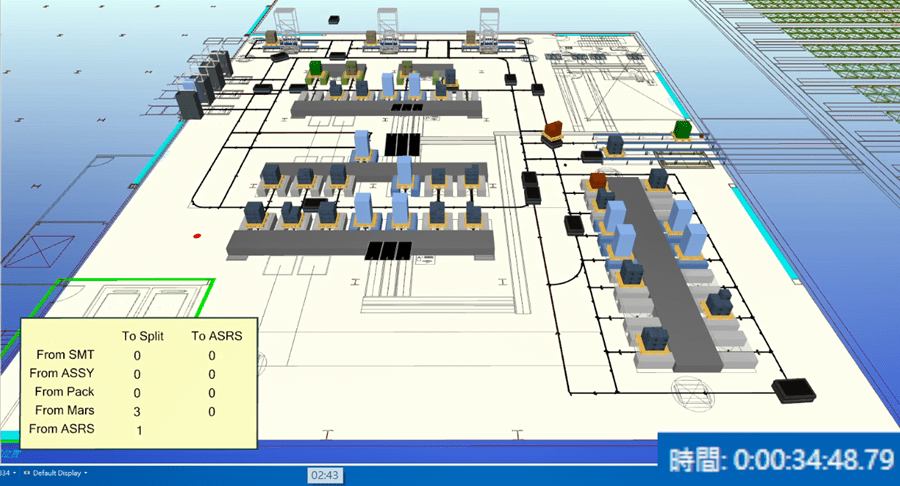

By utilizing digital simulation to create a visualized virtual reality, Emulate3D helps Kenmec Mechanical to establish a complete virtual warehouse and conduct preliminary testing during the planning stage, enhancing project understanding and confidence.

- Assembly simulation

The high-fidelity simulation environment enables Kenmec Mechanical to effectively present actual picking and packing involving both machinery and labor. This early identification of potential risks helps to minimize adverse impacts on production capacity, which further reduces risks during actual operations and improves the precision in warehouse setup.

- Validation testing

By integrating a programmable logic controller into verification, Kenmec Mechanical can test production lines with greater flexibility. This reduces the time that engineers need to spend on retesting the software on site and allows immediate validation post-completion, which accelerates project timelines.