Electric vehicles (EV) are revolutionizing automobile production. In 2017, just four percent of vehicles sold were alternative fuel. Now, thanks to greater investment in technologies, automotive manufacturers will reach parity by 2023 and 54 percent of all new auto sales are expected to be battery powered by 2040. This exponential growth is a window of opportunity for automakers to find partners to innovate their EV manufacturing operations.

Increasing demand for EV means both established automakers and start-ups need to launch new plants or transform existing operations and infrastructures faster and smoother than ever before. New environmental mandates for reduced emissions, automobile trends, government rebates and the rise of ride-share services means automakers must develop the right EV strategy to be competitive and mitigate risk of a recall.

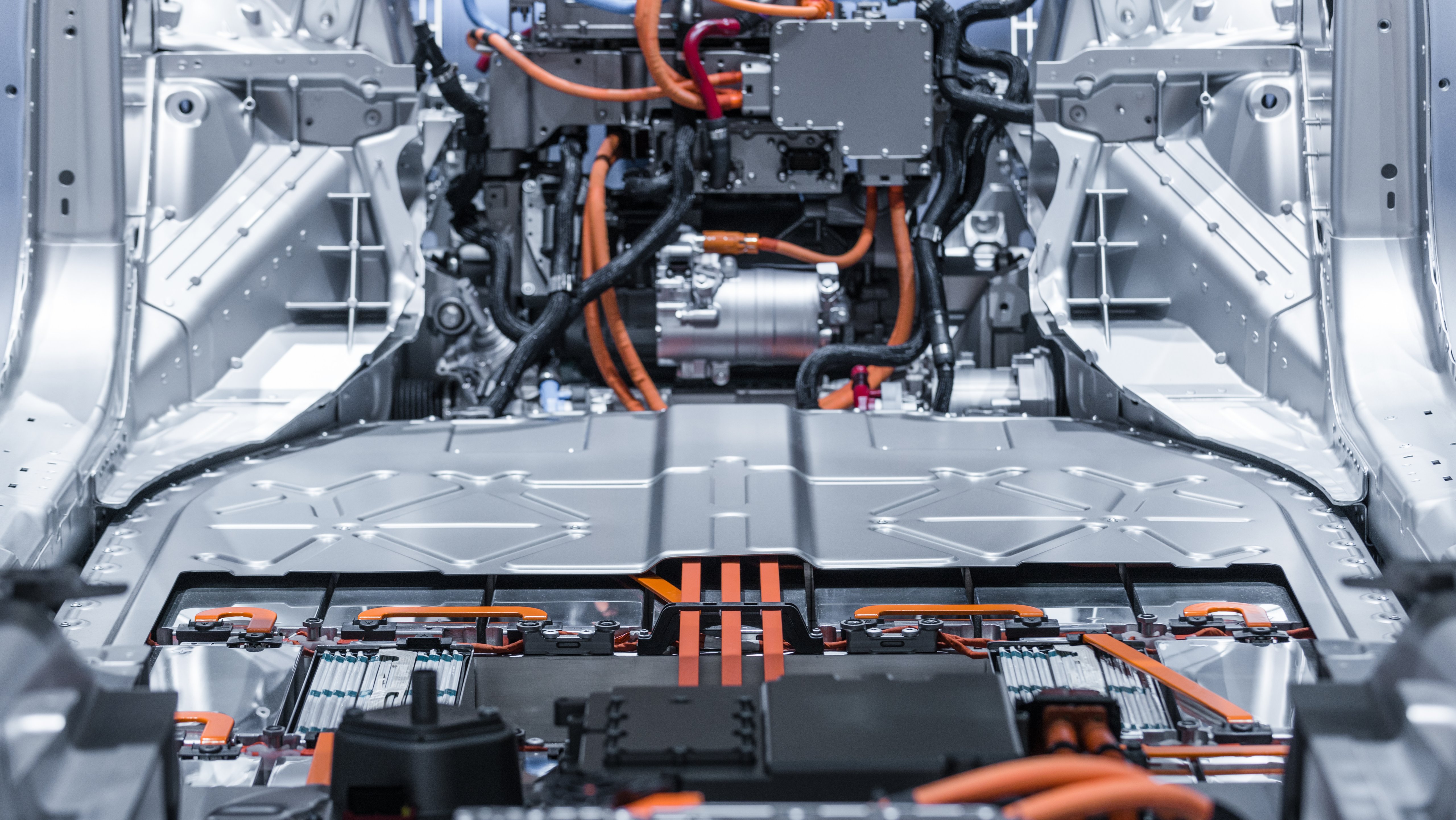

Automakers are calling for innovative solutions from suppliers throughout their entire supply chain to meet increased production demand. Whether you are a machinery OEM for EV automakers, a lithium battery manufacturer or a specialised OEM – producing battery winding machines, there is room throughout the entire EV supply chain to integrate new technologies and improve productivity.

The next transportation technology revolution is here. Technologies such as real-time data sharing, self-aware equipment and independent cart technology are just some of the ways that you can reduce your time to market.

The Future of Automotive Manufacturing is Already Here

Automakers and OEMs alike can benefit from leveraging new technologies to improve profitability. A leading Korean battery manufacturer recently invested in new manufacturing technologies to influence both the quality and energy capacity of a battery cell.

They required high speed and high precision rates to enhance their production capabilities and reduce defective rates, but the existing conveyor system was very limited. This battery maker was seeking a new solution that would meet their requirements, both now and in the future.

A detailed proof of concept study demonstrated the value and capabilities of the flexible, scalable automation platform from Rockwell Automation. The MagneMotion® Quick Stick® intelligent conveyor system provided a solution that was able to meet the end user’s requirements by providing increased throughput and a lower cost of ownership.

Automakers are planning to rollout of hundreds of new electric vehicle models over the next several years and are therefore focused on reducing manufacturing costs and maximising battery life. From battery-cell manufacture to vehicle assembly and throughout the entire supply chain there are opportunities to drive efficiencies and improve profitability for automakers.