Mr. Kanaporn Rujisonthi, Sales Manager, OEM, Rockwell Automation Thai Co., Ltd., said, “Rockwell Automation is a world-class Factory Automation system leader and the world’s first brand of PLC equipment. Currently, the Company has been engaged in this business for more than 120 years and, at the recent ProPak 2023, Rockwell Automation brought in hardware and software innovations to present to interested parties about our existing technology.

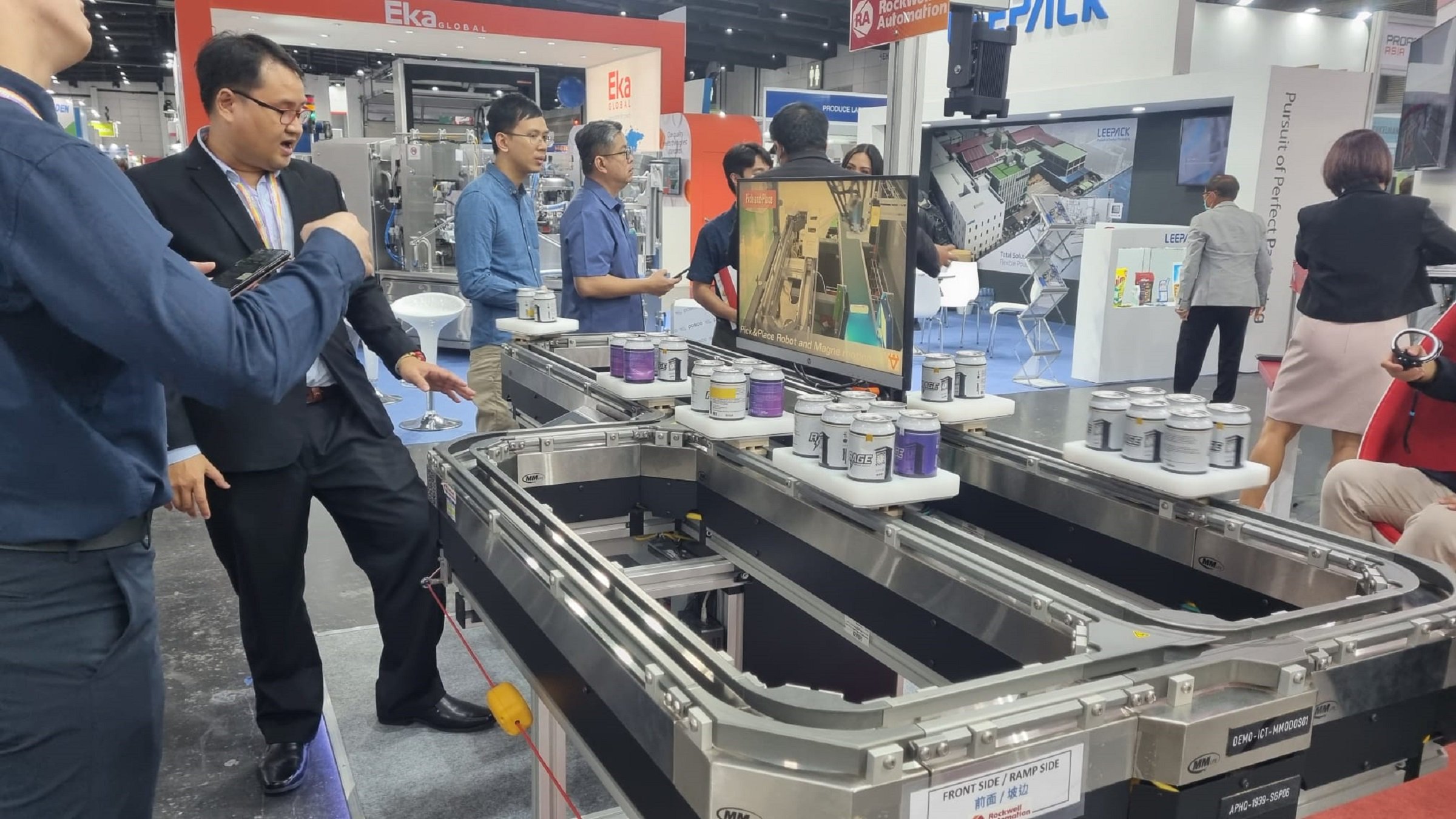

What we had placed on the exhibition was the Magnetic Conveyor system where the working principle of such machine line is the magnetic field linear motor system that helps drive the material conveyance and the material being conveyed will be on the rails which will not come into contact with the rails, thus, resulting in this system to be able to work at high speed with no need for maintenance. Because the material will not have any contact with the rail and the moving speed of the rail system or movers is 2 meters per second, each mover can stop in a customized position without any need to use multiple sensors in the case where the conveyor line is long and suitable for a limited installation space.

Moreover, each mover has its own ID, thus allowing it to have its own data and to be able to know where each of them has moved to whichever point and what numbers it has. We can write programs or feed the data into the system in order to make the movers move to different positions within the machine. In respect of the automated function process pattern of Rockwell Automation, there is a Working Team available to provide advice and consultations to customers by making designs according to the customers’ needs which, in this connection, we have an experienced Installation and Design Team that can also simulate the conveyor’s working process so that customers can see the actual working process.