Recommended For You

People are often encouraged to “think outside the box” to break free from their habitual thinking and address challenges in new ways.

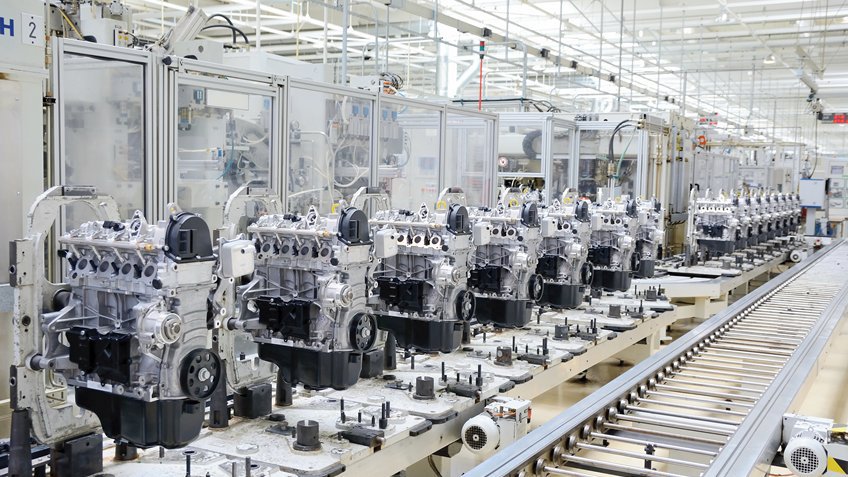

The concept was embraced – literally – with the introduction of the On-Machine™ design philosophy. In this design approach, automation controls and other hardware that are traditionally placed in an enclosure are moved directly onto a machine or closer to an application.

You may think the harsh conditions of a plant floor or industrial operation are unsuitable for panel-based hardware. But On-Machine solutions are in fact hardened and specifically designed to meet environmental certifications and ratings to operate in these conditions, such as using IP67-rated housing for dust and wash-down protection. What some engineers don't know is that they can extend the benefits of On-Machine control to their safety system designs, as well.

Benefits for OEMs and End Users

Removing hardware from the enclosure and placing it close to the machine, also known as decentralizing can significantly reduce panel-space requirements for On-Machine systems. Wiring requirements also are simplified because component connections can reside on the machine in the form of pre-configured, quick-connect systems.

Machine builders can take advantage of this modularity and simplified connectivity to more cost efficiently build a machine at their site, pretest it and then disassemble it for transport to an end user's plant. They also can use On-Machine design to develop more standardized machines. For example, conveyor systems that previously were only offered as large custom systems can instead be created and sold as standard 10-foot sections.

For manufacturing and industrial end users, On-Machine systems that use prewired connections in place of manual wiring can help reduce start-up and commissioning times, improve system reliability, and ease troubleshooting.

Instead of sorting through a complex panel during downtime events, for example, workers can quickly isolate problems and replace components such as starters and I/O locally. The plug-and-play nature of On-Machine systems also gives end users greater flexibility for relocating equipment and making additions with relative ease.

On-Machine Safety

A growing number of On-Machine safety products are enabling machine builders and end users to expand On-Machine systems to meet their safety requirements. This allows them to realize all the benefits of On-Machine solutions while still supporting compliance with today's most stringent safety standards.

For example, On-Machine safety controllers such as this one deliver the full capabilities of a traditional safety controller with SIL 3, CAT 4, PLe, while also meeting global certifications and ratings for IP67 protection. On-Machine safety I/O modules such as these offer similar benefits and can be mounted anywhere on the machine, including close to sensors and actuators for shorter cable runs and reduced wiring costs.

Machine-mounted Ethernet switches such as this one also can be valuable in providing connectivity to the network in applications where cabinet space for system-level networks is minimal or nonexistent, and for operations where widely distributed applications are needed.

Head over to Machine Design to read an article that provides more information about the benefits of On-Machine safety and important design considerations for implementing it.

Published September 26, 2016