Jungheinrich Forklift (Shanghai) Co., Ltd. is part of the Jungheinrich Group from Hamburg, Germany. Since 1953, the brand has been providing forklift handling equipment to customers in the industrial field. It is a leader in industrial vehicles, warehousing technology, and intralogistics.

- Gap between program planning and project implementation

- Inability to detect potential bottlenecks and optimize space in the implementation

- Improve efficiency and accuracy of designs

- Achieve smart transformation of project implementation and debugging models

- Improve project success

- Improve productivity while reducing costs

Challenge

In this era of digital transformation, the value-add that data can provide has become a blue ocean for businesses to be leveraged. The logistics equipment industry, known for its efficiency, is driven by data and continues to transform with new models and forms of smart logistics.

Jungheinrich Forklift (Shanghai) Co., Ltd., part of the Jungheinrich Group that is headquartered in Germany, has been supplying forklift handling equipment to industrial customers since 1953, and is a leading supplier of industrial vehicles, warehousing, and logistics technologies. In a bid for continuous progress, the team noticed room for improvement during the planning phase of projects.

"In the past, many of our planned solutions were actually 'paper talk', although data analysis would be conducted according to the plan. Only when the project really landed could the advantages and shortcomings of the project be detected, and the potential bottlenecks or optimizable space in the project," said Shi Ruohong, technical manager of Jungheinrich Forklift Shanghai Co., Ltd.

The company turned to Emulate3D™ digital twin software to overcome these challenges.

Solution

Emulate3D - Breaking Through Bottlenecks with Virtual Simulation

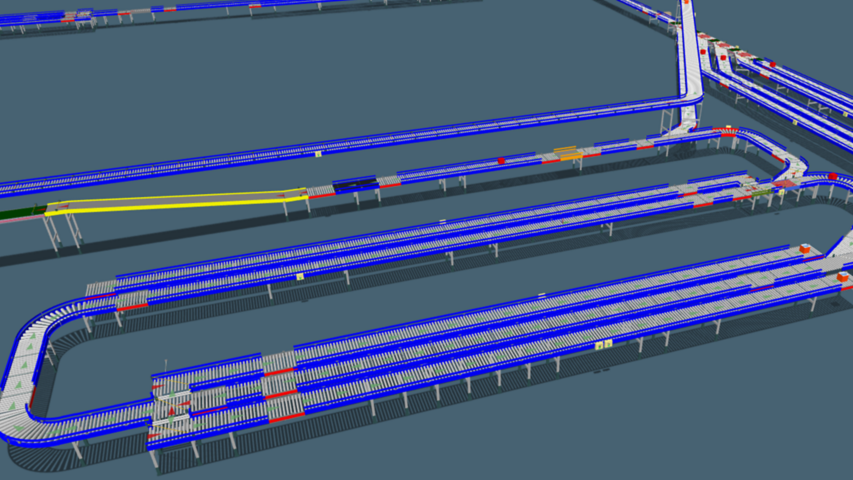

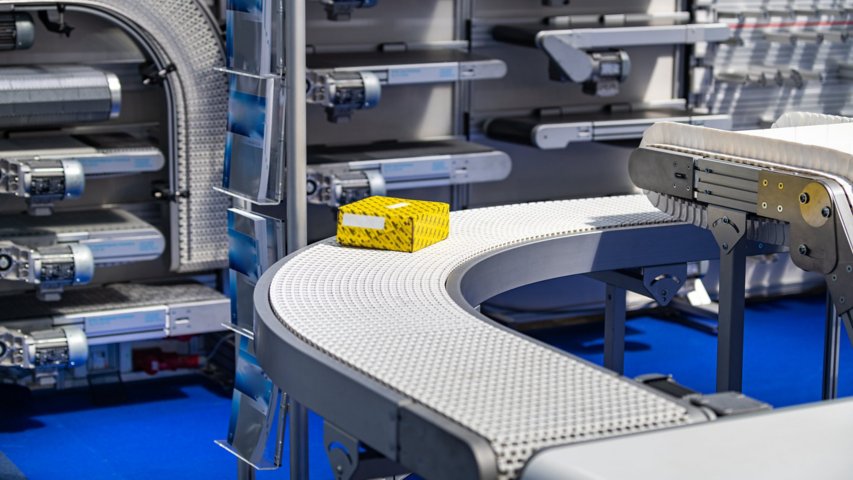

Emulate3D's focus on high-fidelity industrial animation, simulation, and control provided a comprehensive solution. The platform allowed Jungheinrich to create a digital twin of the entire lifecycle of a project from design to implementation, bridging the gap between virtual and real-world scenarios. This breakthrough enabled the team to detect potential bottlenecks, optimize project plans, and accurately predict control system sequences.

Emulate3D's digital design approach can greatly improve the efficiency and accuracy of design, while shortening design time, helping users increase project success rate, improve productivity, and reduce costs.

Emulate3D's dynamic display capabilities were leveraged not only for project implementation but also for creating impressive 3D dynamic case demonstration videos for events like CIIE, an important showcase for Jungheinrich in China. The software's user-friendly interface, combined with a powerful simulation engine, facilitated easy modeling and in-depth development, addressing the team's need for both simplicity and scalability.

Shi shared that with the Emulate3D software's powerful simulation capabilities and 3D visual expression, the team was able to bring to life the complete equipment applied in each point of the project, and the dynamic effects of various application scenarios from storage to picking to handling.

Result

Ease of Use and Scalability

Another important factor that the Jungheinrich team appreciated about the digital twin software is that it is both easy to use and scalable.

Emulate3D's product library includes the main automation products commonly used in the industry, and the shape and action characteristics of the model are highly matched with the actual product. For most projects, the main modeling work can be completed by dragging and dropping directly into the interface. This makes the task easier, even for the less experienced team members, as they can quickly grasp the key points and get the job done.

For more advanced users with complex needs and strong secondary development capabilities, Emulate3D provides a toolbox full of extension functions, to help developers achieve various required functions and effects through in-depth development. Shi added that the combination of Emulate3D's "easy to use" and "strong expansion" characteristics empower the Jungheinrich team to make configurations according to the capabilities of different developers, effectively improving the team's overall efficiency in the face of different types of projects.

Value Expansion and Future Innovations

Emulate3D not only enables the Jungheinrich team to face today's challenges, but also helps them expand their innovative abilities for the future.

Shi shared that Jungheinrich plans to further leverage Emulate3D in virtual debugging, exploring its powerful visualization capabilities. Shi explained that many customers are no longer satisfied with the traditional 2D display but hope to view the operation of the system from all angles from a 3D perspective. The Jungheinrich team envisions using Emulate3D to build highly simulated digital SCADA that accurately represents on-site operations.

Beyond project design and implementation, Jungheinrich aims to extend the value of Emulate3D to after-sales service by developing a VR/AR-based technical support solution. This initiative would allow real-time remote support for end customers' operation and maintenance personnel, showcasing Jungheinrich's commitment to continuous innovation in the logistics industry.

Emulate3D has not only addressed current challenges but has positioned Jungheinrich for boundless possibilities and unlimited expansion in the evolving landscape of smart logistics. The platform's innovative application ideas are expected to shape the future of logistics solutions for Jungheinrich and its customers alike.

Published April 10, 2024