The Australian explosives manufacturing industry has earned an enviable reputation as a global leader in the manufacture of explosives as well as providing the required infrastructure and equipment for the explosives industry both within Australia and around the world.

International Explosives Equipment (IEE) is one of the world’s leading mining explosives equipment manufacturer and supplier. The company manufactures in their custom built facility in Western Australia.

When tasked with building a new explosives manufacturing plant in a remote part of Eastern Europe, IEE knew that there were a number of regulatory and environmental considerations to be addressed.

IEE called on Auto Control Systems (ACS), a recognised Rockwell Automation System Integrator and provider of industrial automation, control systems and services based in Perth, Australia. Within the scope of the project, ACS was responsible for delivering the automation and electrical components of the plant.

The key to the success of the project was to design and build the explosives equipment to meet the production requirements of plant while taking into account the unique environmental factors and transportation logistics.

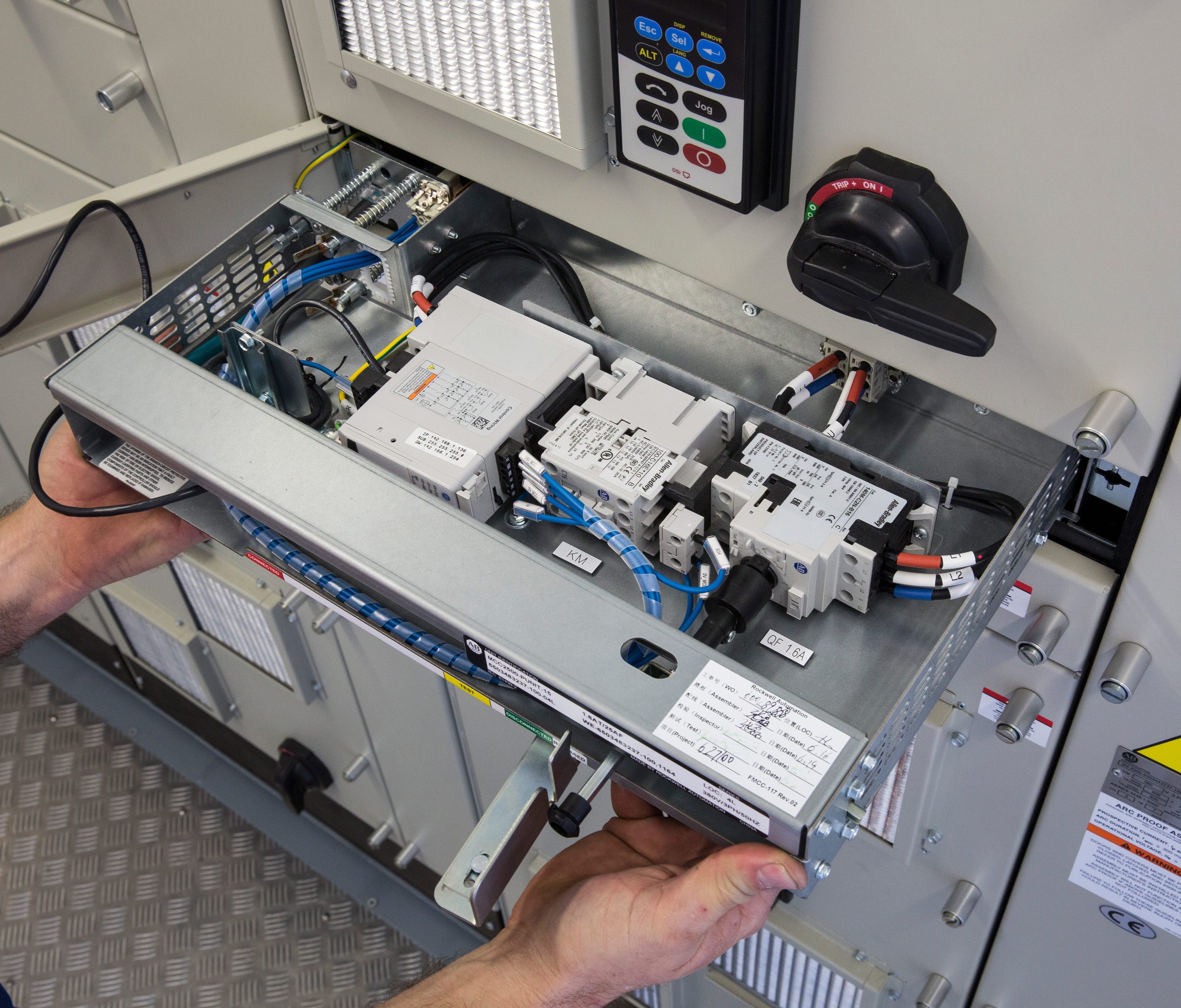

Intelligent Motor Control

Motor control technologies have advanced rapidly, delivering tighter integration between devices and access to data. These advances provide actionable information to help optimise operations.

According to Andrew Taylor, engineering & operations manager, ACS, “Customers around the world are growing more aware of international regulations, including IEC regulations around the Motor Control Centre (MCC) and safety so they are really looking for solutions to meet these criteria.”

IEE, ACS and the end user collaborated on the programming requirements for operating the production facility incorporating a high level of safety, automation and control.