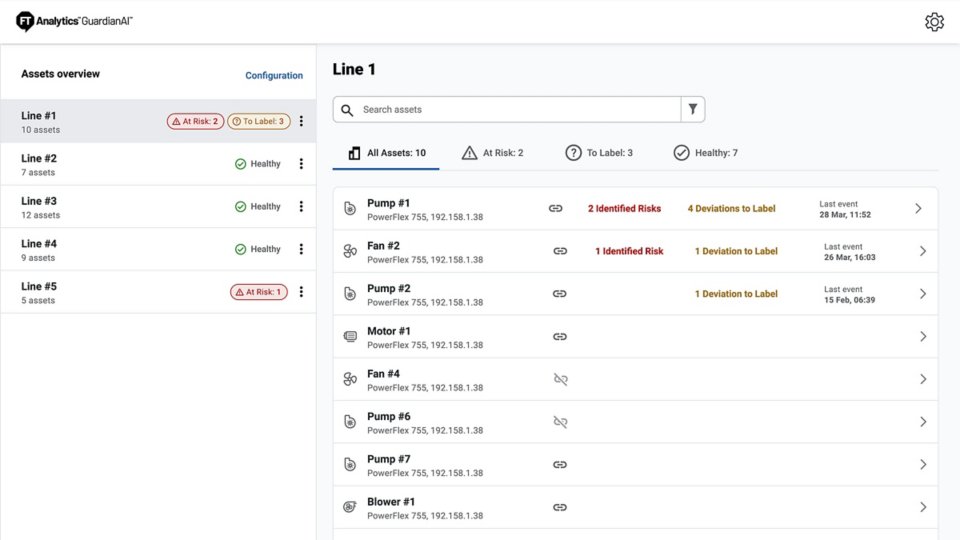

Optimize maintenance activities and reduce unplanned downtime with advanced notice of upcoming asset failures provided by FactoryTalk® Analytics™ GuardianAI™. When maintenance engineers understand the health of the assets on the plant floor, they can plan their tasks efficiently. FactoryTalk Analytics GuardianAI provides continuous condition-based monitoring, alerting the maintenance team when an asset begins to show signs of degradation and providing insights into the most probable cause of failure. With this information, they can plan when to perform the required repair and confirm they have the necessary resources and parts on hand. Repair times are reduced and costly unexpected downtime is avoided.

There’s no need to purchase additional sensors or monitoring equipment. With FactoryTalk Analytics GuardianAI software, you receive early warning of potential asset failures based on data that’s already available from your variable frequency drives. FactoryTalk Analytics GuardianAI software expands on the drive’s embedded health monitoring capabilities by using its electrical signal to monitor the condition of a plant asset. When it detects a deviation in the electrical signal, it alerts you to the anomaly so that you can investigate and plan the correct response. FactoryTalk Analytics GuardianAI software provides premier integration with PowerFlex® 755, 755T and 6000T drives for key process applications like pumps, fans and blowers.

Why FactoryTalk Analytics GuardianAI for predictive maintenance?

Use Your Existing Drives as Sensors

Get more value from your Rockwell Automation devices through premier integration with PowerFlex® drives

Advance from Anomaly Detection to Anomaly Identification

Identify the most probable cause of an upcoming failure with embedded expertise and continuous learning

No Data Science Required

Empower your OT professionals with machine learning through intuitive, user guided workflows

Analyze at the Edge

Train and run right at the edge for near real time predictions

Use Your Existing Drives as Sensors

There’s no need to purchase additional sensors or monitoring equipment. With FactoryTalk Analytics GuardianAI, early warnings of potential asset failures are provided using variable frequency drive (VFD) data. FactoryTalk Analytics GuardianAI provides premier integration with PowerFlex 755, 755T and 6000T drives, leveraging electrical signal data for condition-based monitoring of pump, fan, and blower applications.

Advance from Anomaly Detection to Anomaly Identification

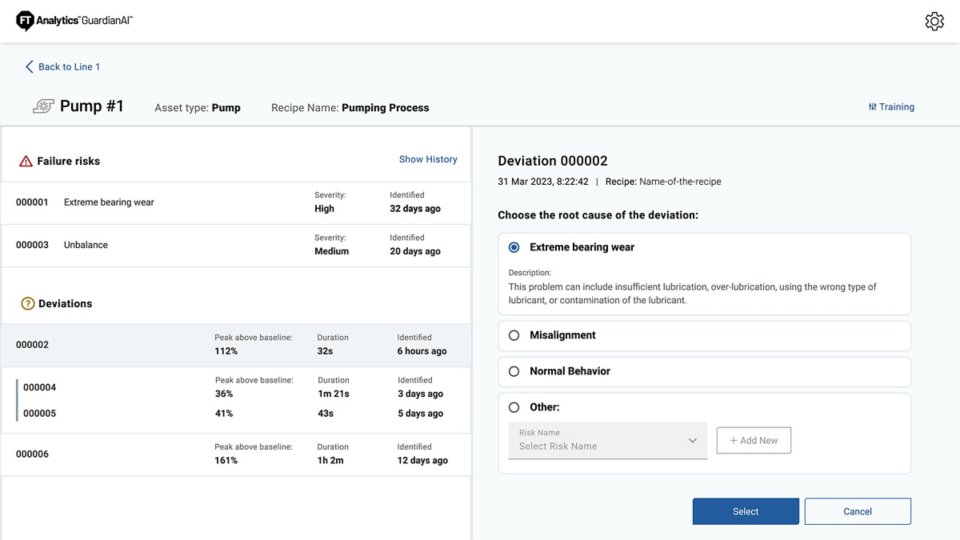

FactoryTalk Analytics GuardianAI goes beyond anomaly detection. It comes out of the box with embedded expertise that not only detects but also identifies the application specific faults listed in the drop downs below. This helps maintenance engineers reduce investigation time and minimize any downtime required. If FactoryTalk Analytics GuardianAI detects an anomaly but can’t identify it, you can teach it to the next time. After you investigate and identify the source of the issue, you can label the anomaly and when the same issue is later detected, FactoryTalk Analytics GuardianAI will recognize it and notify you.

No Data Science Required

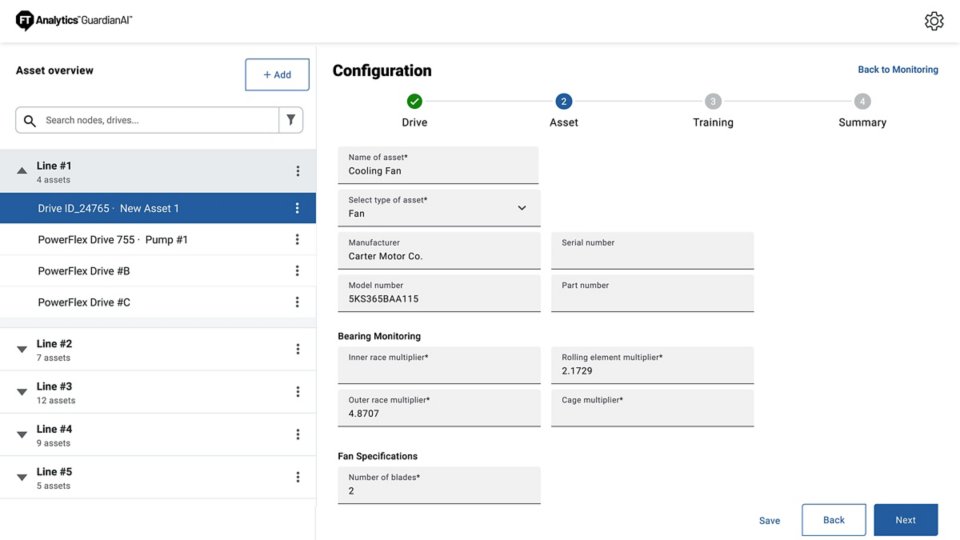

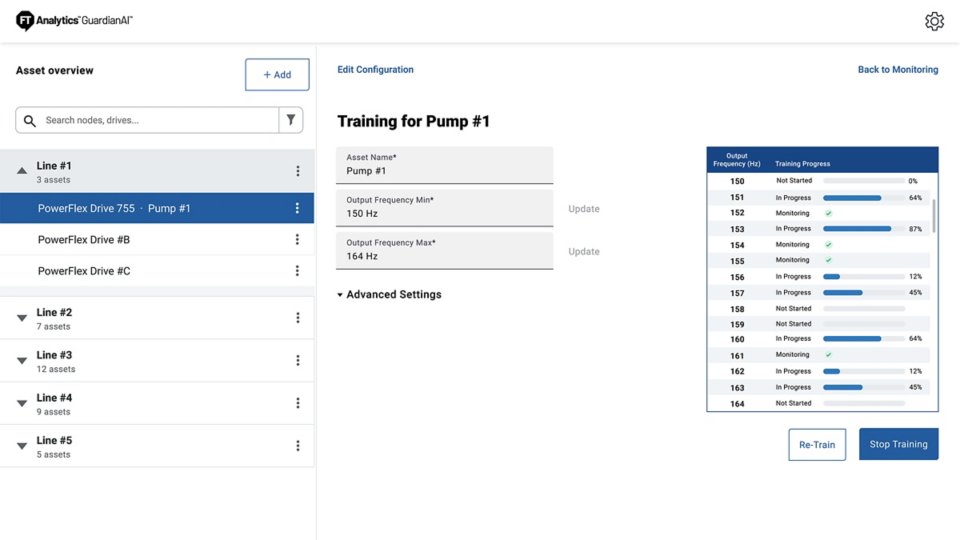

FactoryTalk Analytics GuardianAI provides no code machine learning. It puts AI into the hands of OT professionals with an intuitive four step workflow.

Analyze at the Edge

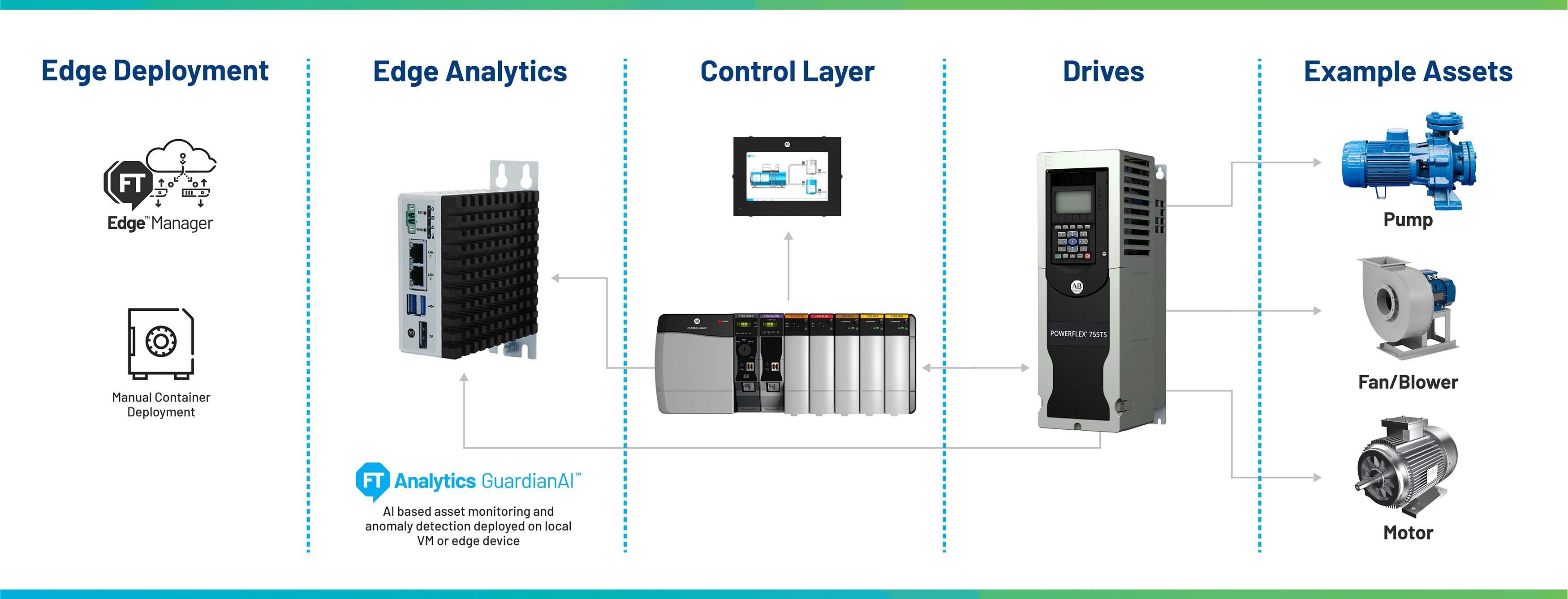

FactoryTalk Analytics GuardianAI is deployed, learns and runs right at the edge. As a result, it can analyze the electrical signal drive data at high speeds to alert maintenance engineers of anomalies at the very first signs of deviation. You can manage your FactoryTalk Analytics GuardianAI edge devices and application deployments centrally, securely and at scale with FactoryTalk® Edge™ Manager for higher productivity and efficiency.

Ready to Learn More About Our AI Offerings?