A Closer Look at the Fermentation Process

One area that represents an opportunity for greater batch efficiency is the fermentation process. And the better you understand and control variables like time, temperature, balling and cooling capacity, the better the fermentation process will be.

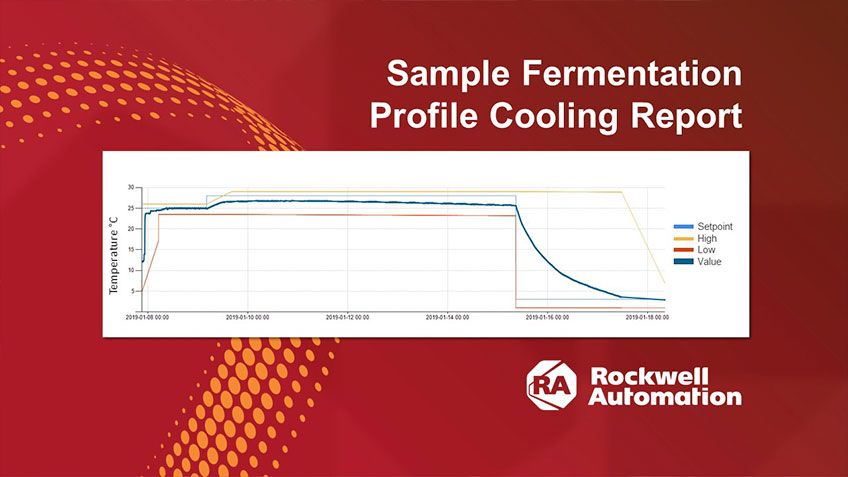

You already know your general fermentation profile for a given recipe, such as an ale set at 65°F for 10 days. Impacting those variables are set points for temperature control, cool on time, fill volume and primary fermentation time that follow a recipe that has worked before, so you continue to use it.

But what if you can hit these targets in less time? Predictive analytics can reveal hidden efficiencies that are easily attainable for any operation.

Maybe your recipe calls for a batch to sit in fermentation for 10 days to get the desired Plato. But in actuality, you can do it in 8 days and still get the same alcohol content and taste profile. Manual monitoring may not accurately identify this trend, but an analytic watching trending data can alert you to this 2 day recipe change that can have a domino effect on capacity and overall brewhouse efficiency.