The Oxford Landing Estate Vineyard and Winery is named after a site where drovers once grazed and watered sheep. Today it's home to a loyal flock of down-to-earth folk who take great pride in making quality wines, enjoyed the world over.

With 650 acres under vine, Oxford Landing Estate is not small but by micro-managing 130 five-acre blocks as separate ecosystems, the grapes are given exactly what they need to achieve optimum flavour.

Techniques such as detailed pruning, canopy management and crop thinning provide the winery with ultimate control in expressing the individuality of each block. Oxford Landing prides itself on being nimble enough to harvest small batches of the fruit as soon as it ripens, so not an ounce of freshness is lost.

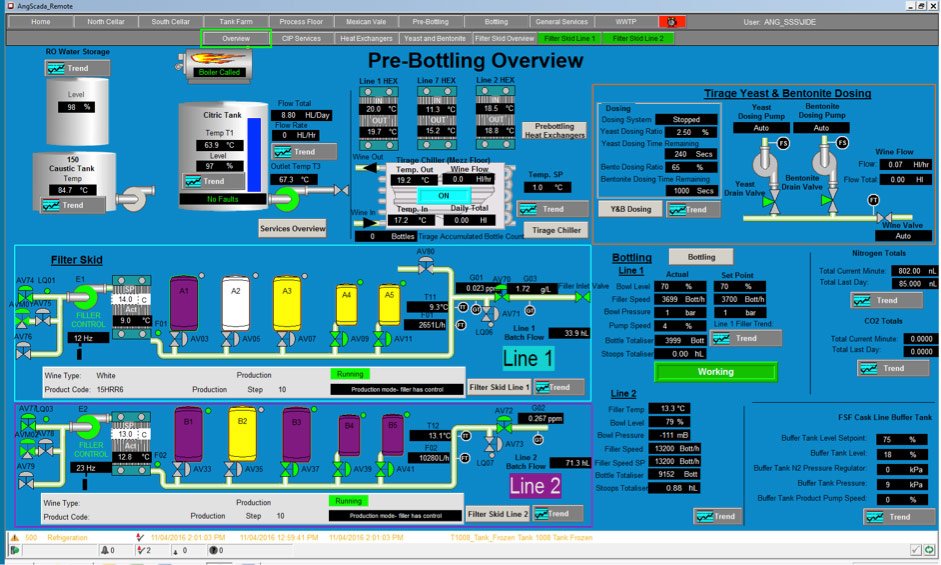

Set on the northern edge of the Barossa Valley the key to the success of the Oxford Landing Estate Winery is their ability to achieve a continuous production flow via a sophisticated automation and control system. In winemaking, this timing is particularly crucial since the grapes need to be processed within a critical window of time where the acid and sugar content are at a premium.

To achieve this, together with keeping up with increasing consumer demands, winemakers are turning to technology to streamline the process.

Over a Decade of Service and Support

Yalumba is Australia's oldest family-owned winery, and one of the country's largest wine exporters. Its Angaston winery was founded in 1849 in South Australia's famous Barossa Valley. Over time however, the demand for Yalumba wines has grown to exceed the processing capacity of the heritage-listed Angaston facility. This led to the establishment of the Oxford Landing Estate Winery, which is now the primary producer of Oxford Landing Estate wines and Yalumba's popular two litre cask wine varieties.

One of the main challenges with winemaking is that customers expect consistency, they get used to a particular label and expect it to taste the same, but every year the acid level is different, the sugar content is different as are the aromas and colour of the berries.

According to John Ide, winery operations manager, at Yalumba, “The aim for the Oxford Landing winery was an environmentally friendly plant incorporating the latest in winemaking technology, plus a new and unique process stream methodology. The objective was to achieve greater management of the process and the product.”

The agility needed to meet the demands of frequently changing production demands was uniquely met by the process automation solutions from Rockwell Automation. This on top of the end to end efficiencies of the plant wide control inherent in Integrated Architecture truly made this a solution real win for Yalumba.

The Oxford Landing Estate Winery was commissioned in 2005 and has been able to meet market requirements and improve product quality for more than a decade now. The secret, says Ide, is the automated process streams that ensure the grapes are fermented under optimum conditions, given the high volume throughput. It is particularly critical at all times to control fermentation rate and minimise oxidation, both of which are highly dependent on temperature.

From the moment the skin is broken during harvesting, it's important to move the product quickly through the crushing stage, chilled and into the controlled environments of the fermentation tanks.

Each process stream begins at one of three receive hopper/crusher bays, where loads of grapes are converted into ‘must', a mix of juice, skin and seeds. The must is then pumped through one of three ‘must chillers' to reduce the temperature to around 12 degrees Celsius for white and heat or cool to 25 degrees for red. To produce white wine, the juice is extracted from the skin and seeds and clarified prior to fermentation; conversely, red wine is fermented with the skins included in the fermentation vessel. For both styles of wine, the premium juice/wine or ‘free run' is drained and kept separate from the second stream or ‘pressings' of extracted product through subsequent processing and storage. After wines are fermented they are clarified and blended into the final product before filtration and bottling.