Paving the Way to Smart Cities

Our luminaires are packed with technology. They are almost endlessly configurable to meet the needs of any public lighting space:

- They can be motion activated, so that they only come on when needed by a passing vehicle, bicycle, or pedestrian, before dimming to reduce light pollution and energy use.

- They can be fitted with environmental sensors so that they report back air quality readings or detect gas leaks.

- They can even be fitted with microphones capable of notifying authorities of accidents and automatically raising the lighting levels for emergency services in attendance.

- They can be fitted with 5G antennae to bring whole areas into the next era of mobile connectivity, ready for the smart mobility solutions of the near future.

- They can count and monitor traffic and include cameras to improve traffic flow or safety.

Moreover, they can do all of this from a central control dashboard and be remotely managed.

Naturally, the needs of a luminaire in a pedestrian city centre will be different to those on a highway, a residential road, or a cycle path. Even the traditional lighting functions of our luminaires offer huge variance to meet the different lighting brightness levels, colours, and cabling requirements of a particular local authority.

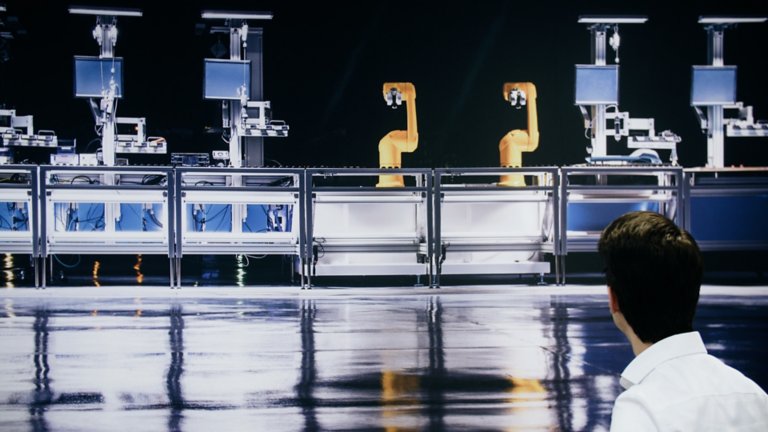

Smart Ideas Demand Smart Factories

Being able to offer our customers such a diverse range of capabilities requires an advanced manufacturing capability. One that is immensely flexible and can convert the precise configuration requirements of each customer into a production process that is highly efficient, despite the product variance.

This, I think, is one of the most interesting challenges for the future of digital transformation. Technology is making all sorts of things possible, but given our existing infrastructure, be that on city streets, or in factories all around the world, how do we bridge from what we have, to what can be. How can we scale disruptive technologies if we manufacture them in traditional ways? How can a start-up company, like Sustainder, offer digitally enabled manufacturing benefits to its customers in a way that is competitive to large competitors?

The answer, in our case, is also a proof of concept for the Factory-as-a-Service model. What we needed was a hugely capable manufacturing facility that we didn’t have the money to build, and wouldn’t, initially, have the orders to maximise. We needed existing supply chains, advanced ERP, MES, and fulfilment skills. To compete with big international lighting producers, we needed to benefit from similar – or more advanced - manufacturing capabilities and scale, without actually being able to build that from scratch.

The Factory as a Service

Our solution is the Technologies Added shared smart factory in Emmen, NL. By working with a factory as a service, we have the use of their facility, including the Rockwell Automation digital backbone that allows us to set up configurable production lines quickly, enabling ‘mass customisation’ – the flexible and highly scalable process vital to offering our product variance.

The factory provides access to advanced technologies and capabilities, such as 3D modelling, smart robotics, digital twins, and data-driven manufacturing, which allows us to create production orders from our configurator software. That is then implemented by the experienced staff and manufacturing process capabilities at Technologies Added.

The great benefit of our model is how light and scalable it is. We look to a future of much bigger contracts that will require Technologies Added to continue to grow to absorb our requirements, and potentially to replicate the model at further sites, perhaps in different locations to be closer to major markets. Importantly, the manufacturing methods at Emmen can be directly replicated from the Rockwell Automation digital backbone, meaning that the process of adding exponential output capability to Sustainder is relatively straightforward.

A Flexible Approach to a Brighter Future

Another exciting aspect concerns how the new manufacturing methods in the Sustainder model offer a new direction for luminaire manufacture – and perhaps the scaling of other disruptive technology start-ups in the future.

Whereas lighting furniture was previously sold as a one-off, which was expected to operate for 25 years or more, the interchangeable cassettes (brains) of our luminaires offer the opportunity for the initial sale of a system to be the starting point of a continued relationship that adds or changes functionality as it is needed or becomes available. Further down the line, this also opens up the distinct possibility of developing different relationships with our customers. We might, for example, be able to change from single purchase (capital expenditure) to a model that factors in the Total Cost of Ownership (TCO) over the lifecycle of the equipment and is purchased ‘as a service’ (an operational expenditure model).

While such possibilities are not being actively investigated at present, Sustainder has the inbuilt flexibility to explore such ideas in the future. This is helped by the fact that by operating on the Factory as a Service model, Sustainder employees are wholly focused on what we do best: the sales and development of lighting solutions, the software engineering of municipal lighting systems, the hardware engineering of cutting-edge luminaires and our customer and technical support operations. The manufacture and the digital backbone that makes it all possible is fulfilled and will be modified and improved over time by companies dedicated to remaining at the cutting edge of what they do – manufacture (Technologies Added) and automation and information solutions (Rockwell Automation).

For Sustainder, this adds up to a bright future as we expand the limitations of public lighting for a smarter, safer, more connected, and more climate conscious future.

You can find out more about how Sustainder and Technologies Added work together in the Rockwell Automation film, produced by BBC StoryWorks Commerical Productions and presented by Digital Europe as part of its “Digitally Enlightened” series.