Hanyang Packaging and Engineering, Inc., one of the largest packaging companies in Korea, has extensive experience in automatic packaging machines and front/back feeders.

A popular traditional snack in Korea is made out of laver, or seaweed (in Korean, ‘kim’). Seaweed is a very thin material and can be cracked during the packaging process; therefore, the packaging is processed manually. As market demand and production increased, Hanyang packaging decided that implementing automated solutions by advanced machines was a viable alternative.

Automated Solution to Meet Market Demands

Hanyang was facing two major challenges. First, delivery delays due to human error – inefficiency has increased due to human errors caused by manual handling of seaweed pavement, delayed delivery of goods due to inaccuracies and lack of flexibility.

Second, as market demand grew, there was a need to increase productivity and output. As the existing labor force made it difficult to meet the production needs, Hanyang wanted to implement an automated solution.

Smart Machine Design Enables Smart Manufacturing

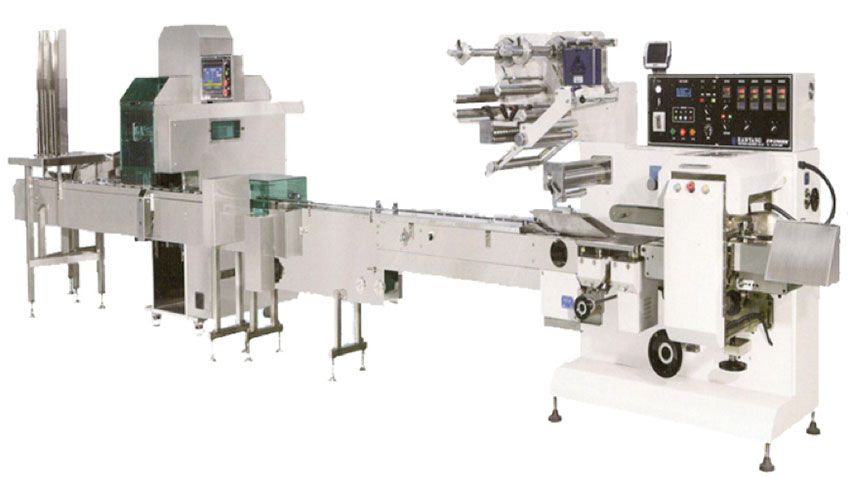

To keep up with the increasing demand, Hanyang Packaging took an innovative approach to smart machine design. Unlike conventional equipment that includes a separate robotic control environment, Delta Robot using Rockwell Automation Integrated Architecture relies on one control platform for the entire system — from robotics control to indexing and conveyance. Using only a single control platform enables improved connectivity both in terms of network and hardware.

As part of the Integrated Architecture system, the CompactLogix 5370 L3 controllers use the same programming software, network protocol and information capabilities as all Logix controllers, providing a common development environment for all control disciplines. The single control environment means the entire system can be managed from standardized controllers and one control touch screen. The function of kinematics within the controller added to the overall machine design simplicity and easier accessibility to maintain.

In addition to the CompactLogix controller, the Rockwell Automation system includes Allen-Bradley Kinetix 5500 servo drives and VP-Series servo motors. The servos control the Delta Robot as well as the indexing motion exactly.

“One Allen-Bradley CompactLogix 5370 controller provides all the processing power we need from beginning to end,” said Kee Hoon Kim, solution architect from Rockwell Automation. "By integrating robots and all servo drives into one controller, and Kinematics in Logix's standardized CIP Sync / motion platform, we can easily control advanced motion by maximizing user programmability."

The loader is monitored using Allen-Bradley PanelView Plus 7, ideal for applications like monitoring, controlling and displaying information in dynamic ways where operators must quickly understand machine status and make better decisions.