How do you know which outcomes are most critical? One thing is certain, if you wait for your customer’s request for quotation (RFQ), you’re already too late. Think about it. By the time the RFQ is generated, your customer has likely determined the capabilities required based on existing applications – and has accounted for similar technology.

OEMs who have been most successful in ICT implementations have a deeper, more advanced relationship with their end user that’s not simply reactionary. In other words, they have established a dialogue with their customers to uncover business challenges where ICT can drive significant value.

Some examples?

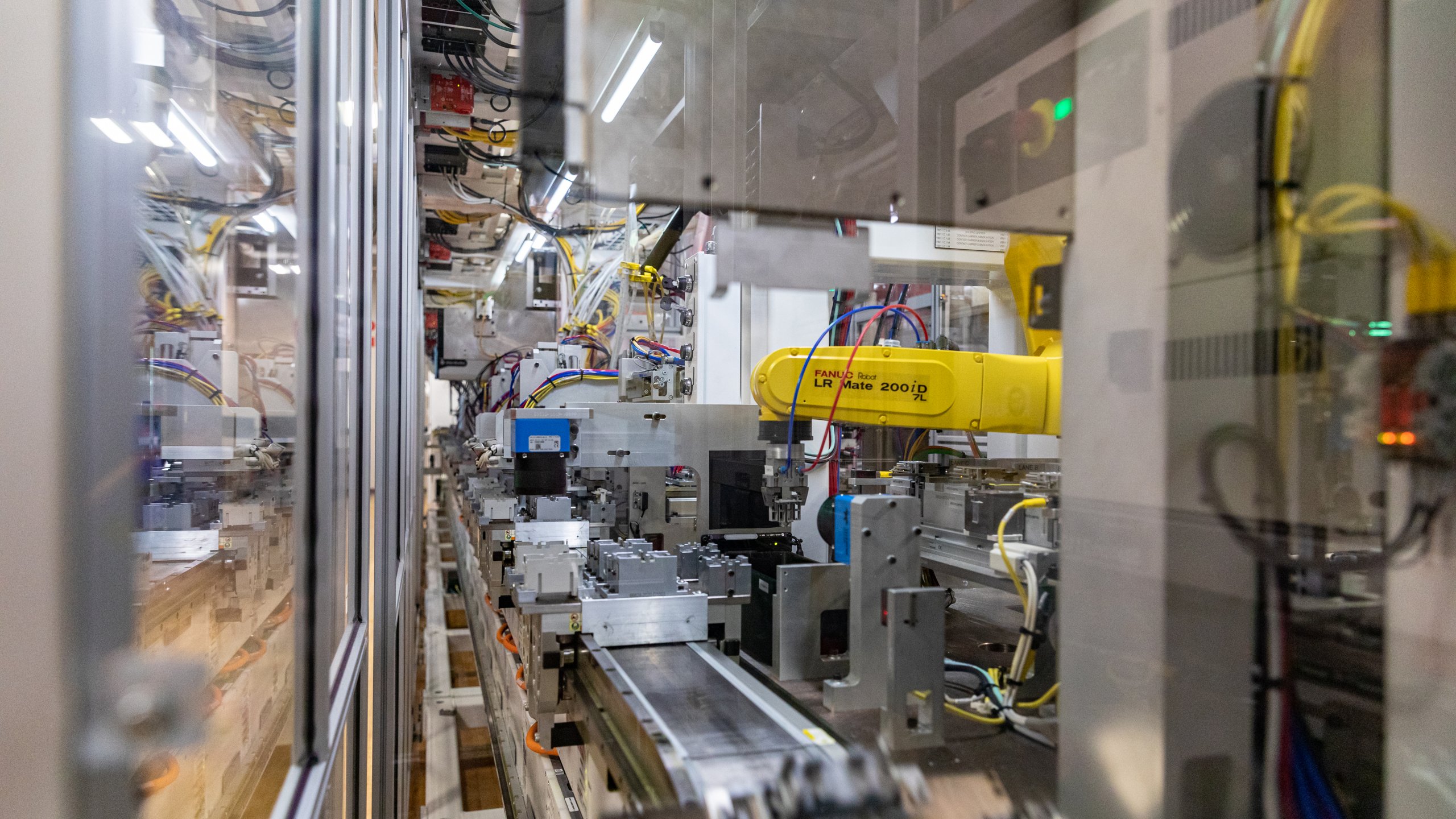

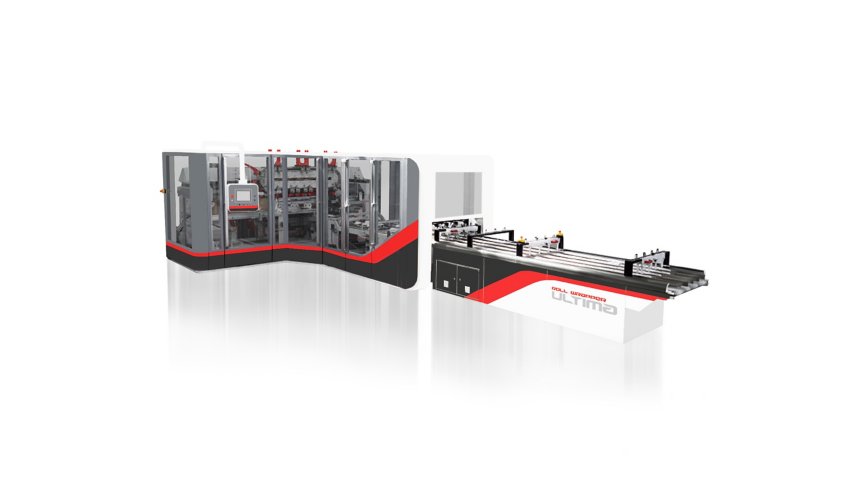

- Beyond its unmatched ability to optimize highly variable packaging applications, ICT also conserves floor space – thanks to efficient track configurations and self-contained electrical components.

- In addition, ICT features a smarter, simpler design that can ease operation and maintenance by a less-skilled, constantly revolving workforce.

- And ICT can even combine intermittent and continuous motion in a single solution to solve complex application challenges that formerly required multiple machines.

Add Simulation. Improve Operational Certainty.

As a machine builder, you know that adding any new technology to your portfolio has the potential to delay projects or introduce other implementation risks. And while ICT enables simpler operation on the plant floor, it does require a mindset shift during machine design.

For example, while a conventional belt- or chain-driven machine might have just one or two axes of motion driving it, an ICT system will have an axis of motion for every individual carrier on the track. Depending on application, that could mean going from two axes of motion to 20 or 60 or more.

So from a design perspective, how do you determine exactly how to configure the equipment to achieve optimal results – and minimize rework?

The answer is simulation/emulation software. These digital tools deliver dynamic models – or “digital twins” – that can be used to solve technology challenges in the virtual world early in the equipment development cycle. Much more than a 3D representation, digital twins enable you to actually run, modify and rerun your machine – before you’ve ordered any ICT hardware or cut any steel.

Adding simulation to your ICT project also delivers a whole new level of operational certainty to your customers not possible any other way. Imagine showing customers exactly how a machine will operate and dialing-in adjustments before equipment is built. How much time would it save during the factory acceptance test (FAT) and beyond?

Value That Grows with Your Business

Recently, we have seen more end users consolidate and centralize their internal engineering resources. To address shrinking expertise at the plant level, I predict end users will ask their machine suppliers for more operational support than they have in the past. And that will likely include equipment adjustments, retrofits and validations that were formerly the purview of staff engineers.

With ICT and simulation, you can better support customers throughout the machine lifecycle. Gone are the days of arriving on site with a crate of parts – hoping for the best. Instead, you can drive more value and certainty by testing modifications virtually alongside your customer. And boost customer confidence by getting it right the first time.