“We chose the Allen‑Bradley® CompactLogix™ for the distributed control of the solar, battery, flywheel and switchgear because it helped to lower the cost, minimised space and IO, whereas the dynamic resistor enabler used ControlLogix® due to the large program and number of IOs,” he explained.

Challenge

- To develop a hybrid energy system and reduce Flinders Island’s dependence on diesel for electricity

Solutions

- Allen‑Bradley® ControlLogix® and CompactLogix™ - Provides seamless integration of control and communication equipment with fast and reliable delivery of data

- FactoryTalk® ViewPoint - Provides real time information of the status and important parameters, and operators have access to alarms via phone or email

- FactoryTalk Historian - Provides operators quick access to historian data, enabling them to generate a quick report of parameters for analysis and diagnosis

Results

- The Hydro Energy Hub system is capable of displacing 60 percent of the annual diesel fuel used to generate electricity with ‘diesel off’ operation for 100 percent renewable penetration

Located off Tasmania’s north-east Coast, Flinders Island is about 60 kilometers from north to south and 37 kilometers from east to west, with a total land area of more than 1,300 square kilometers.

Until recently, Flinders Island was heavily reliant on expensive diesel fuel to supply its electricity. It was supplied by the 3 megawatt (MW) power station, serving 6.7 gigawatt hours of annual customer demand, peaking at 1.3MW.

Hydro Tasmania, with the support of the Australian Renewable Energy Agency, developed the Flinders Island "Hydro Energy Hub" – a hybrid system capable of displacing 60 percent, on average, of the annual diesel fuel used to generate electricity on Flinders Island. This system is also capable of "diesel-off" operation, providing 100 percent renewable penetration when conditions allow.

With expertise in delivering world leading solutions to reduce diesel generation costs in remote and off grid power systems, Hydro Tasmania offers proprietary integration technology coupled with high quality market source equipment, to provide an optimised renewable energy solution.

As part of this project, Hydro Tasmania developed a number of proprietary technologies that are both scalable and modular, to minimise engineering time and costs.

Scalable and Modular Renewable Energy

According to Ray Massie, Manager Hybrid Energy Solutions, Hydro Tasmania, “the key to a secure and reliable hybrid system are the enablers supporting the renewable generators to maximise their contribution while maintaining security of supply.”

“The scalable and modular units plug into existing diesel stations to form the core of the new hybrid power system. The Flinders Island project involved the integration of new renewable generation into the existing power system to help ensure secure and reliable power supply,” he explained.

Each enabler system has been provided with local HMI for local access so operators can manage monitoring, diagnostics and set point entry.

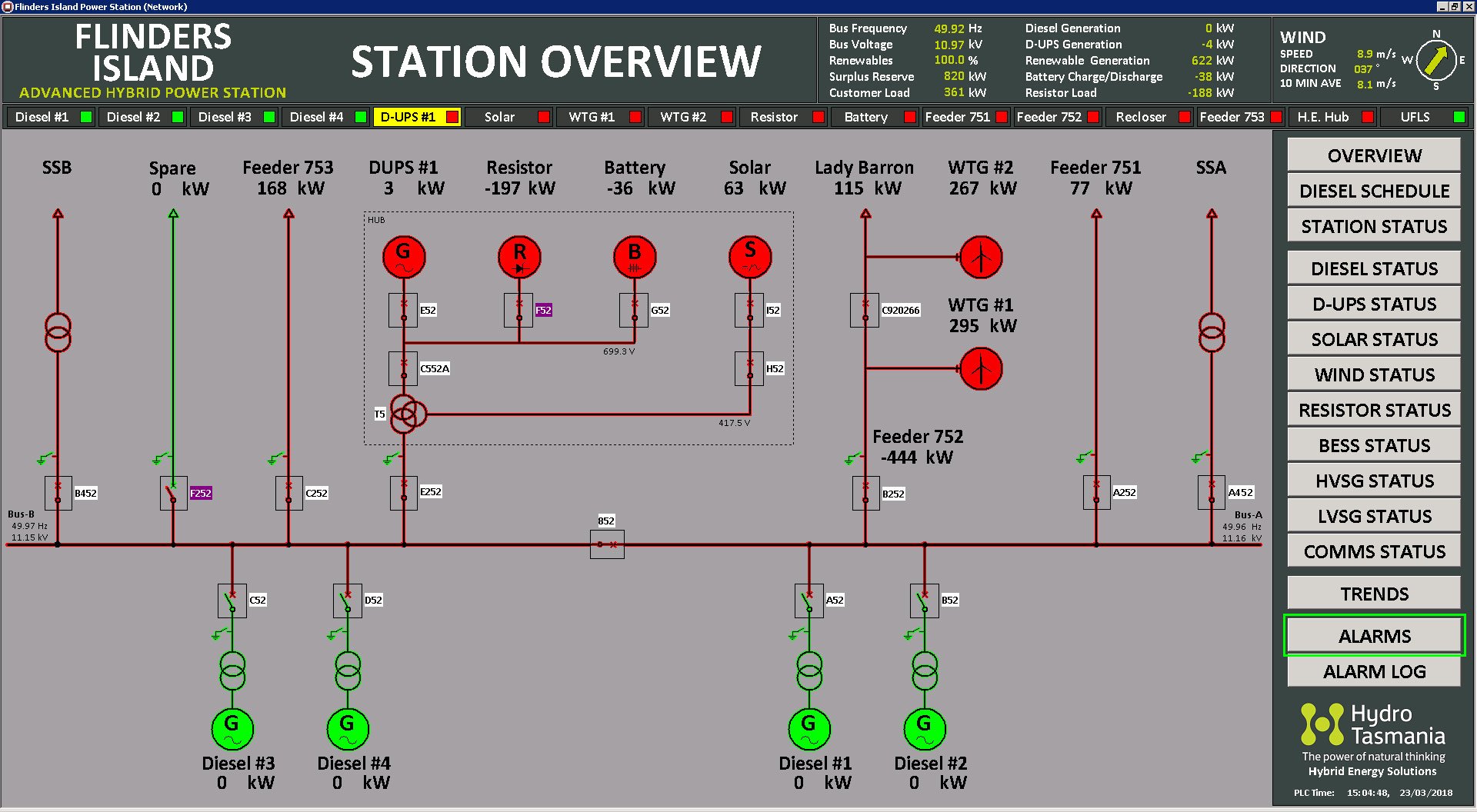

Hydro Tasmania constructed a single 900kw wind turbine and 200kw solar array. The enabling system includes a 750kw/300kwh battery, a fly wheel and synchronous condenser, and 1.5MW dynamic resistors, which is transported and housed in scalable modular containerised units designed by Hydro Tasmania.

Keeping the Power Station Under Control

“For the control requirements, we chose Rockwell Automation products for all the systems because of the consistency, reliability, availability and ease of integration. This includes timely delivery support by the local Rockwell Automation Authorised Distributor, NHP Electrical Engineering (NHP),” Massie said.

NHP prides itself on providing custom solutions tailored to customers needs, supported by expert service.

The power station control system was founded on proprietary PLC code developed in-house by Hydro Tasmania and run on the Rockwell Automation system architecture, which provided seamless integration of control and communication equipment with fast and reliable delivery of data.

The system is based on distributed control with a main supervisory control that manages all distributed enablers and power generating equipment.

Hydro Tasmania developed a number of proprietary technologies that are both scalable and modular to minimise engineering time and costs.

The main hybrid power system controller that manages all distributed enablers and power generators works to ensure reliable power and maximum diesel fuel savings. Due to the complexity of managing continuous variability in renewable energy sources and customer load, the main controller is capable of the demanding task of ensuring renewable resources are maximised and optimised.

ControlLogix control systems have the inherent speed to respond to these challenges and also has the capability for decision making to provide reliable and quality power supply to the grid.

The ControlLogix® processor was selected due to its speed, reliability and ability to provide seamless integration of control and communication equipment.

“Another challenge that had to be addressed involved receiving electrical data in real time in order respond to demand variability. The Allen‑Bradley PowerMonitor™ 5000 provided a great response time to achieve these results,” said Massie.

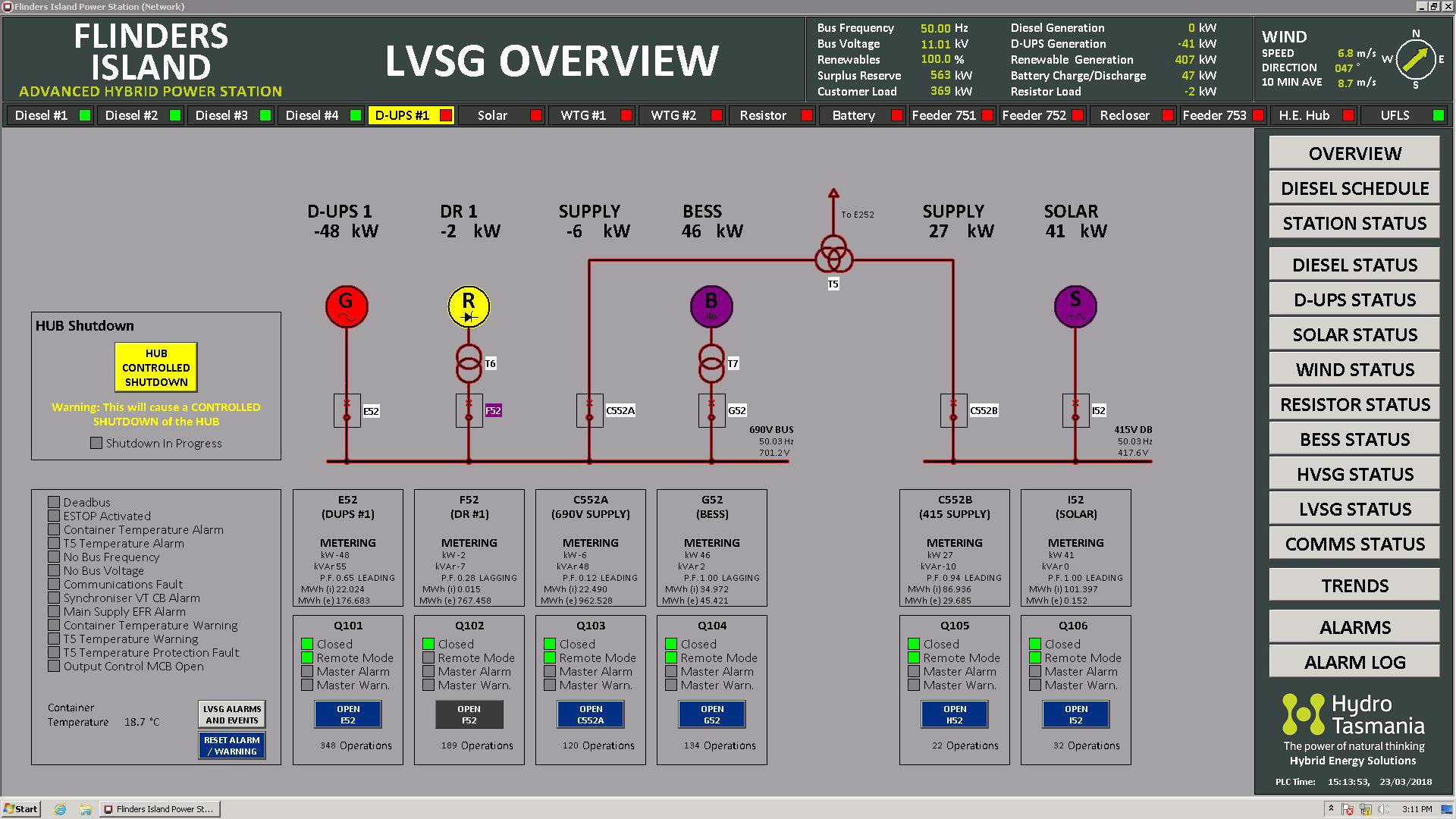

The main control screen gives operators a real time summary of power system performance.

Plant Visibility and Remote Monitoring

During the commissioning of the project, there were some components that did not communicate with the Ethernet/IP network and therefore ProSoft gateways were selected to allow for better integration. ProSoft, a Rockwell Automation Encompass Partner, provides products that are designed specifically to deliver non-core network connectivity for the Rockwell Automation architecture.

The backbone of the network was based on Stratix® switches, providing reliability and integrity to the network for transferring data securely across the power station.

To provide visibility to operators, three FactoryTalk® View SE stations were used – two in the power station and one in the control container in the hybrid enablers’ area, located 50 meters away from the power station main building.

“Each enabler system has been provided with local HMI using PanelView™ Plus for local access so operators can manage monitoring, diagnostics and set point entry. Studio 5000® and FactoryTalk® View Studio provided a common platform for programming all the controllers HMI with the convenience of using the same data structure and reusable tools,” Massie said.

The power station can be monitored remotely using FactoryTalk ViewPoint HMI, providing real time information of the status and important parameters. Operators also have access to power station alarms when offsite and for remote sites visibility via phone or email to help ensure timely attention to alarms.

FactoryTalk Historian provides historical data for optimising the system and commercial decision making. The system also provides operators quick access to historic data, enabling them to generate a quick report of parameters for analysis and diagnosis.

“We leveraged the capabilities of Rockwell Automation TechConnect support who were prompt to answer our queries and when we had any issues they assisted us to resolve it professionally,” said Massie.

Reliable Renewable Energy

The Flinders Island project was successfully commissioned and in operation on October 2017 and was officially launched by Grant Every-Burns, Chairman of Hydro Tasmania in December 2017.

The Flinders Island Hydro Energy Hub is a showcase for innovation and achievement, dramatically reducing the island’s traditional dependence on diesel generation. At the time of the launch the power station achieved more than 92 continuous hours of 100 percent renewable generation, a world record for a megawatt scale non-hydropower system.

To date the system has achieved over 2000 hours of accumulated 100 percent renewable “Diesel-Off” operation with an average renewable energy penetration of 57 percent.

Allen‑Bradley, ControlLogix, FactoryTalk, PanelView, Rockwell Software and Stratix are trademarks of Rockwell Automation, Inc.

Published May 6, 2018

Recommended For You