Reducing Risk

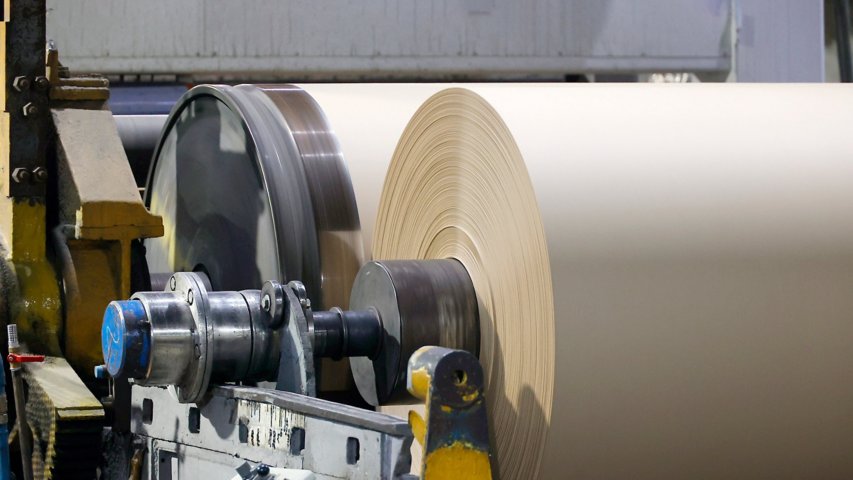

The new mill was the first paper mill built in Wisconsin in over 35 years and was built by one of our PartnerNetwork™ OEMs: Voith. This was the first time in U.S. history that a single company has provided machinery to support a complete paper production facility and they chose Rockwell Automation as the automation partner.

The scope of this build was very large. There were days where more than 1,100 people were working together to bring the new plant online. Rockwell Automation led the network design, provided engineering and design consulting, and coordinated commissioning and installation of power and automation equipment. “Rockwell Automation was very involved with the engineering and design of the new mill,” Matt shares. “They helped us manage integration of the various project pieces, so we knew we were covering the important bases and not missing anything as we went through the process.”

Enabling the Workforce

The company’s focus on retaining existing staff meant that upskilling was needed. Bob explains, “We had challenges in terms of training. The staff all knew how to make paper. They knew how to drive the car, right? But they were driving a 1957 Chevy and the challenge was teaching them how to operate and maintain a 2022 Corvette.”

The Rockwell Automation Lifecycle Services team developed a training curriculum and hosted classroom and field training for the employees to get them up to speed. “Rockwell Automation was instrumental in our success,” says Bob.

Optimizing Operations

The new mill contains modern equipment with embedded diagnostics and over 800 sensors that measure data on equipment and process performance. “This is Papermaking 4.0,” says Bob. “This data allows us to use predictive analytics to maximize and optimize all of our quality specifications, real time as we’re producing the paper, so we can ensure we deliver the highest-quality product for our customers.” The data also enables predictive maintenance, and the ability to schedule work orders before equipment runs to failure – saving the company time and money by reducing downtime.

The new mill is powered by Allen‑Bradley® motor control solutions, including PowerFlex® 755TM drives and CENTERLINE® MCCs that use IntelliCENTER® Software. Safety was a key focus, so the power equipment was designed to meet the safety requirements specified by Voith and the mill layout was designed to minimize forklift traffic.

Automation is implemented using ControlLogix® and GuardLogix® controllers, and operators monitor system performance and issue commands using the PlantPAx® Distributed Control System. A centralized control room allows operators to collaborate, share information, and make better operational decisions. The PlantPAx DCS control screens are built with grayscale design that aligns with industry standards and makes important information easily visible to operators.

Maintenance staff can visualize equipment status using ThinManager® enabled mobile tablets and the mill uses FactoryTalk® AssetCentre on a centralized server for automated software change management control and in the event disaster recovery is needed.

Pairing these technologies with a larger production board machine allows the new plant to achieve more than twice the output of the old plant.

Driving Sustainability

In addition to optimized operation, the new mill is built with sustainability in mind. The alignment with modern corrugator sizes reduces waste. The boiler now runs on natural gas instead of coal, and leftover heat is reused throughout the facility. Finally, the new mill leverages a state-of-the-art water treatment system that significantly reduces the amount of fresh water required to support the process.

“With our new mill, we’re able to make more quality product and get it to our customers when they need it. We’re environmentally efficient, sustainable, and you know, as we continue to use the data we’re collecting, it’s only going to get better,” says Bob.