Downloads

What is this for?

Context

Esterification reactions are very important in the process industry, generally esters are used in the chemical industry and in the food industry, these reactions are characterized by a reaction model.

Objective

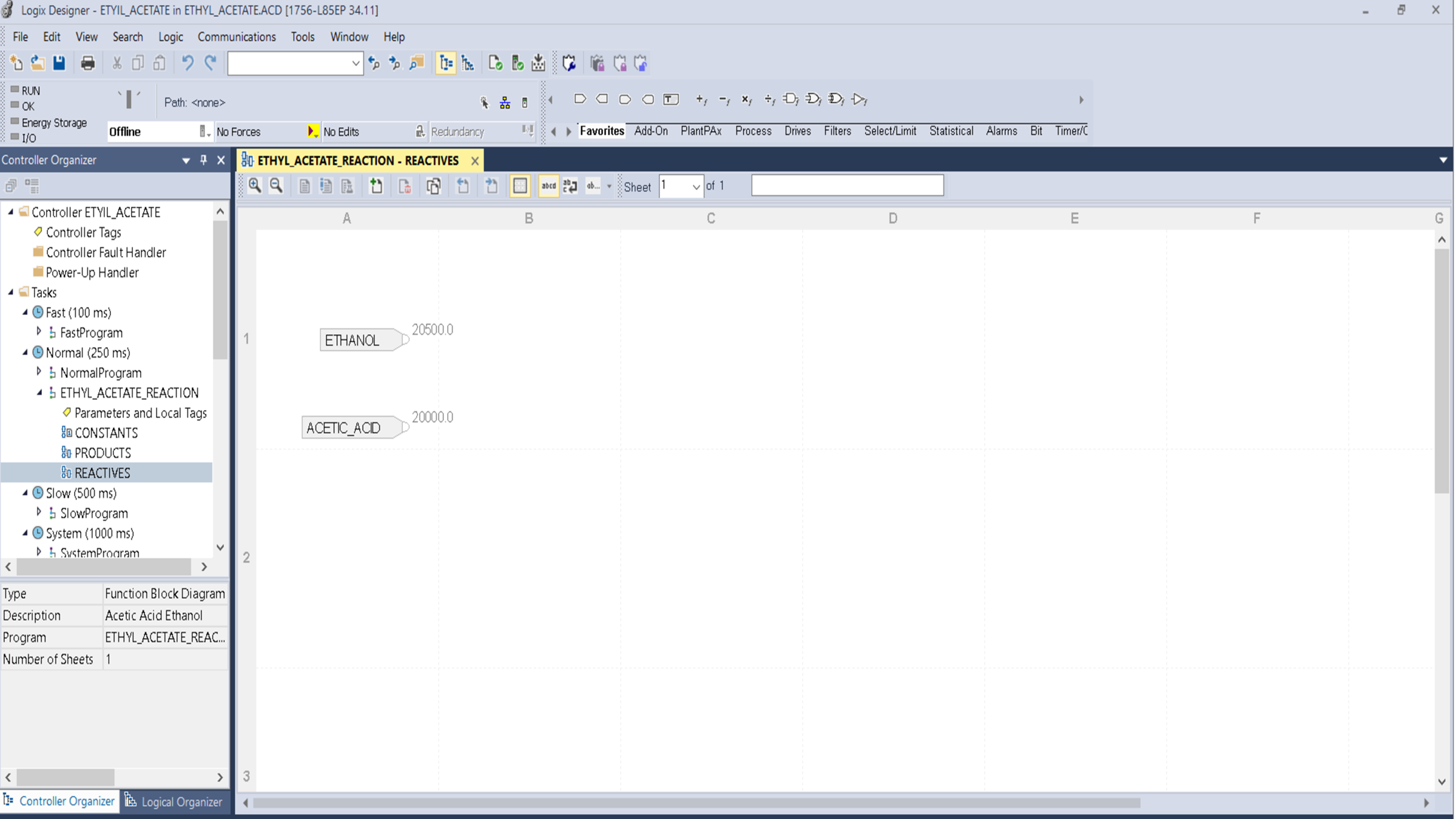

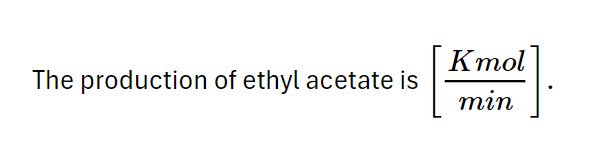

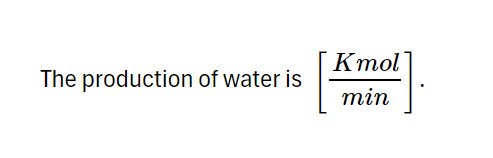

Use the ethyl acetate reaction as an example to verify that the reaction model represents the reaction model in Logix.

How to use

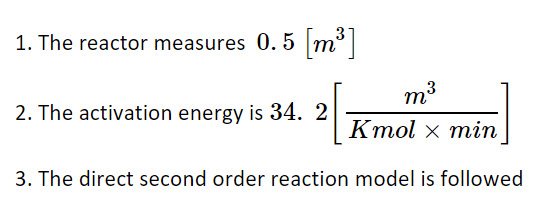

Assumed items:

Limitations

In the current configuration, the chosen reactor is an ideal perfect mixture reactor (ideal CSTR) so that in the liquid inside, it is assumed that:

- There are no gradients in any of its properties and, therefore, the conditions of the output streams are the same as those of the fluid within it, this to simplify the implementation of the configuration.

- In the reactor there is no evaporation of any of the components and, additionally, the adiabatic process is considered.

- Mixture properties are not considered, that is, the properties of the mixture will be the weighted sum of the properties of each of the species.

- The properties of substances are all independent of composition and, therefore, invariant over time.

- Although the reaction is reversible, the reverse reaction can be considered negligible.

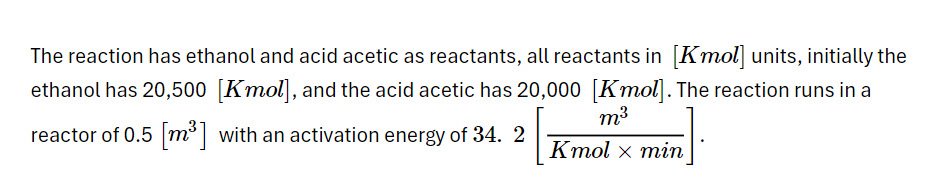

Problem to be addressed

The idea is to have an initial configuration element, to be able to start the configuration of a reaction model.

The reaction model is useful because it could be used for other developers to represent Fischer–Speier esterification reaction model, between carboxylic acid and alcohol.

How can I make it work?

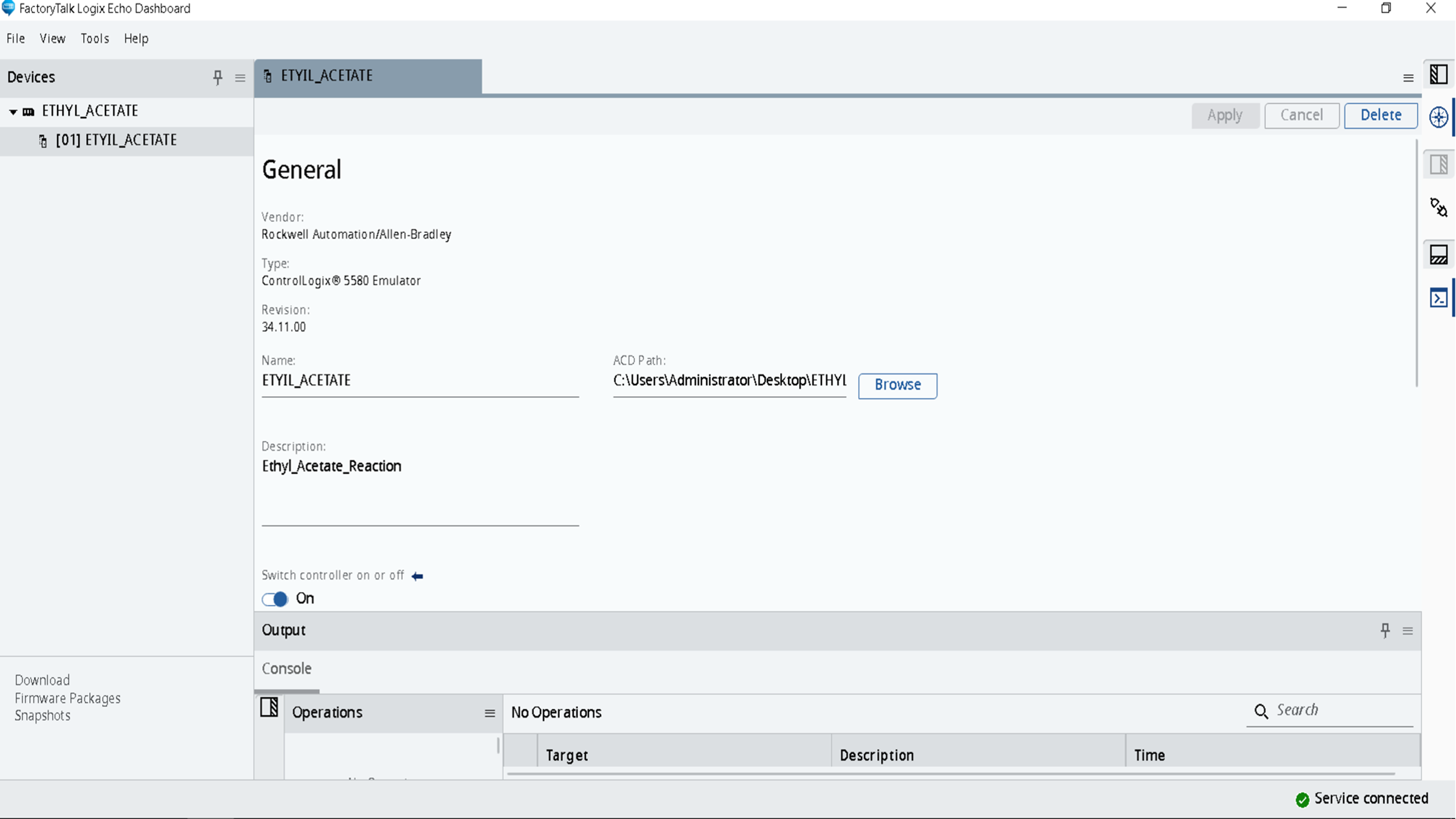

| Products | Studio5000 34.11.00 FactoryTalk Logix Echo V3.00.00 |

| Knowledge | Reaction Model |

External Links

https://www.sciencedirect.com/science/article/abs/pii/S0926860X0300694X?via%3Dihub

Please note: You will need to agree to the Terms & Conditions for each download.

Need Help?

If you need help with an application or have feedback from the Innovation Center, please contact us.

Installation Guide

To implement, check the steps below.

Step 1

Step 2

Step 3

Step 4