Petroleum companies around the globe are seeking ways to meet increasing customer demand while also achieving aggressive sustainability goals.

In 2019, Rockwell Automation began a project with a leading Latin American petroleum company whose leadership believed that the answer to this riddle lay in improving water management.

The company injects pressurized water into reservoirs to increase overall oil recovery and maintain a consistent oil production rate. How much oil they produce in a certain amount of time is directly related to how much water they’re able to inject into the reservoirs. And we’re talking about a LOT of water. For every 100 barrels the company extracts, 98 are water and 2 are oil.

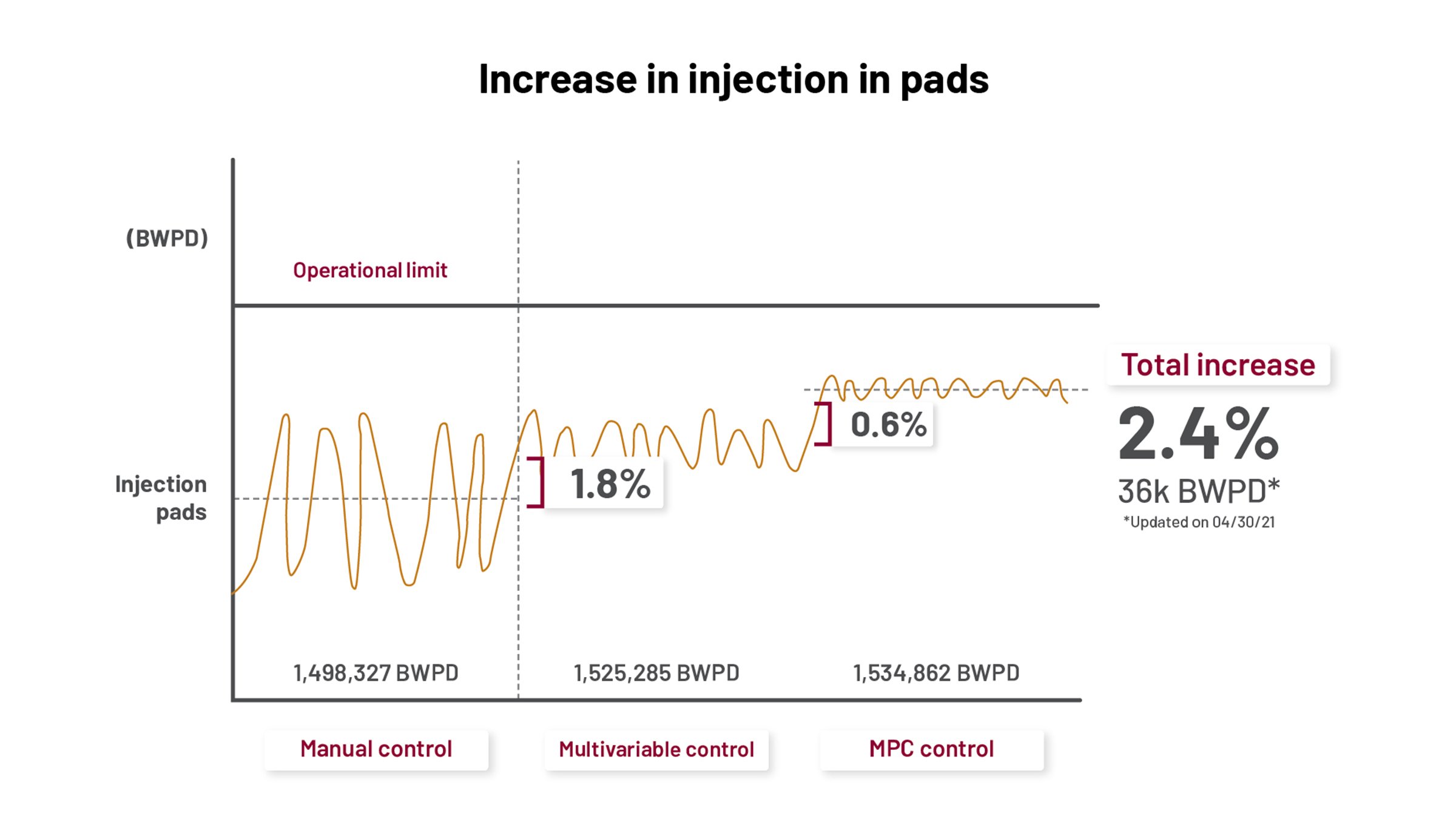

Although the field in question had a high level of automation, there were still opportunities for process control improvements because there were no control loops in place. There was also an outstanding issue with instability in the water transfer and injection process. In the face of any operational disturbance, the injection or transfer pumps were turned completely off, which led to significant oil production losses.

The company approached Rockwell Automation looking for a solution that would increase water injection, reduce the variability of the injected flow and energy consumption, and create a stable system. As one company executive shared, “We knew it would be a win for us to use Rockwell Automation technology, since our entire installed base is supplied by them and we have a history of working together.”

“We wanted to design this project in a way that would give our customer the same level of confidence we had in the solution we were providing.”, says Rockwell Automation engineer, German David Gonzalez Gonzalez. “The contract was subject to a performance indicator: 1% increase in water injection. We divided the risk between the company and ourselves.” And so, Rockwell Automation and the company joined forces to take on a two-part goal: increase water injected by 1% and reduce energy consumption per barrel injected (kW-hr/barrel).