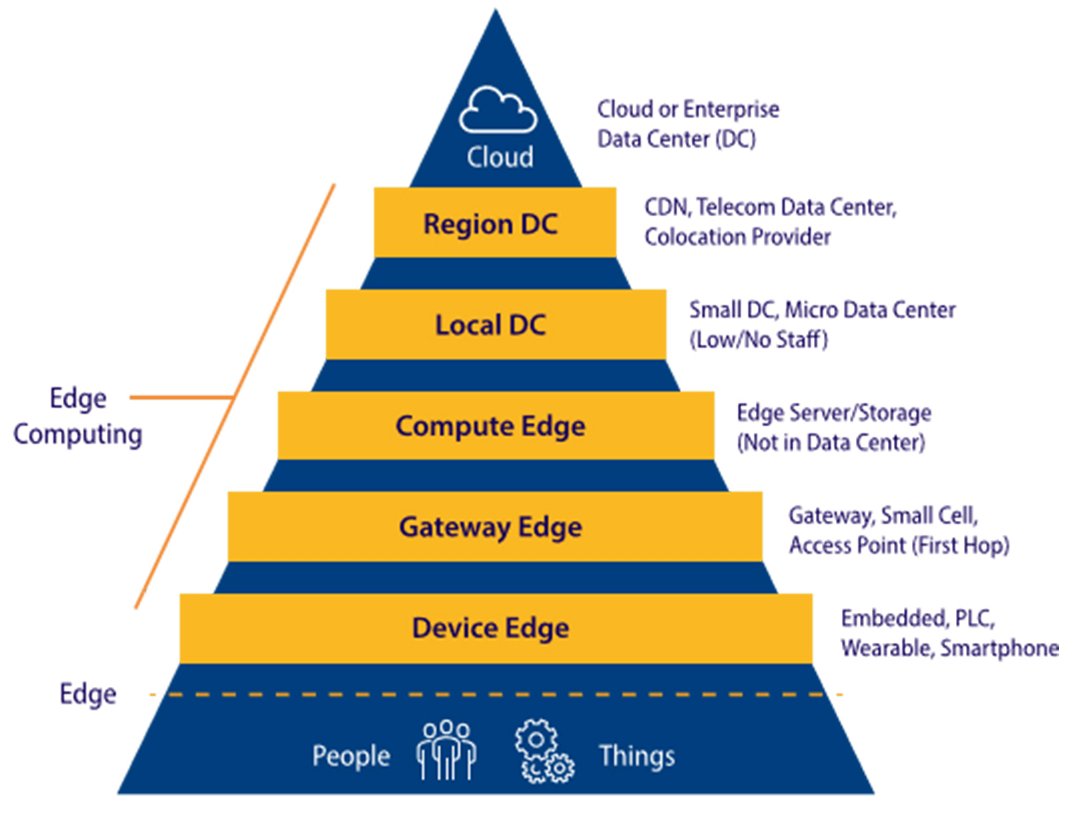

According to Gartner, Edge Computing is part of a distributed computing topology where information processing is located close to the edge — the physical location where things and people connect with the networked digital world.

Figure 1: The scope of Edge Computing involves automation and control of a plant or facility from edge to enterprise. Image source: Gartner

As businesses continue to digitize their operations, many have turned to Edge Computing to modernize and optimize processes, improving the efficiency and effectiveness of their critical automation and control solutions.

This blog post contains four real-world examples of how Edge Computing is being used by Rockwell Automation customers to improve their automation and control solutions.

The growing significance of Edge Computing in the Age of Digitalization

Businesses are facing new challenges as they continue to digitize the operations that traditional automation and control architectures are not designed to manage. Edge Computing is an innovative approach that can overcome the challenges of traditional architectures including islands of automation, unplanned application downtime and data loss, and the lack of a simple way to manage solutions.

Edge Computing consolidates software applications and eliminates silos.

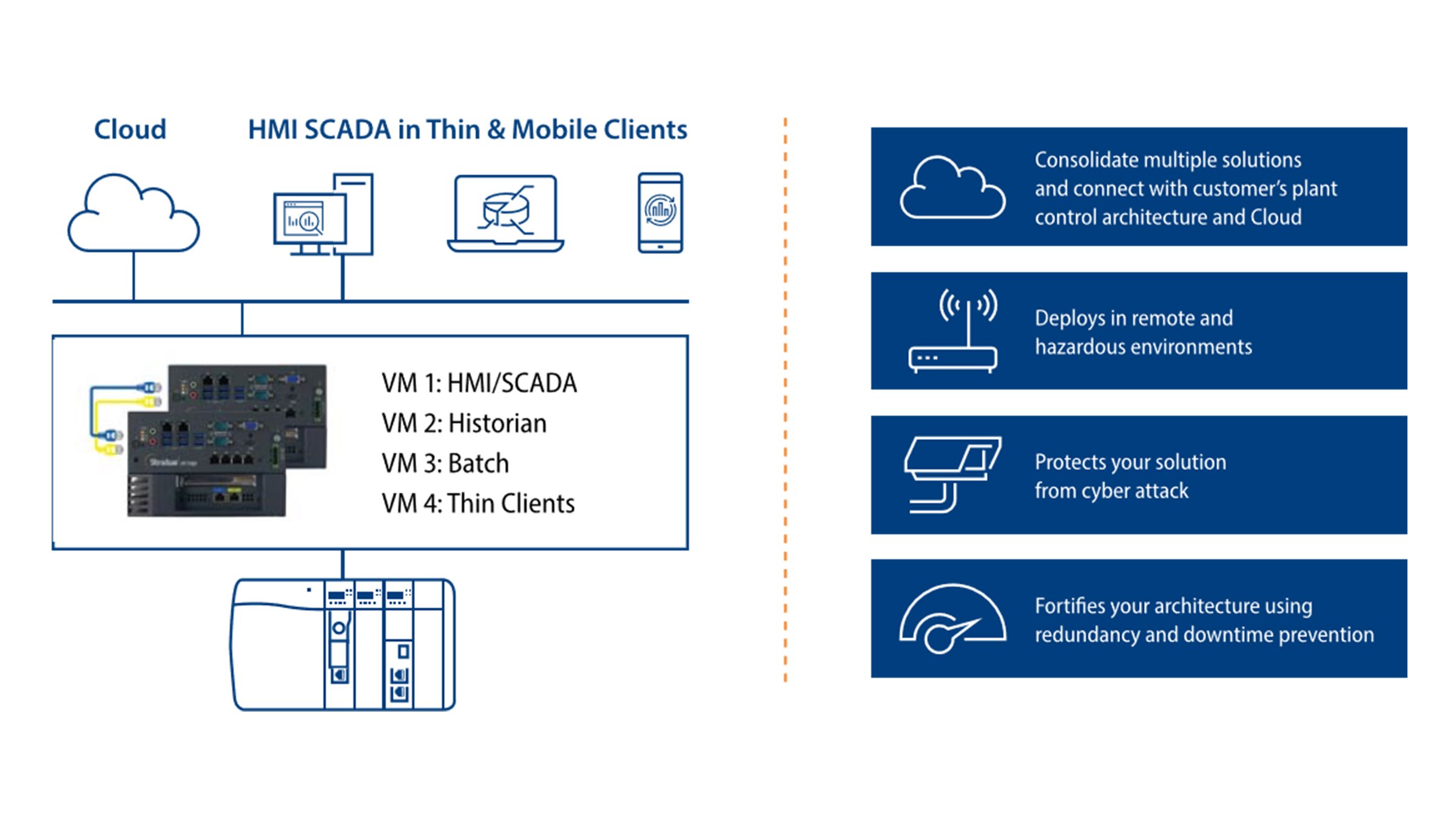

With industrial-grade Edge Computing solutions from Stratus, a Rockwell Automation Global Technology Partner, users can consolidate software applications onto a downtime-proof device.

Figure 2: Stratus Edge Computing platforms come with pre-configured virtualization and built-in redundancy enabling consolidation, improving management, and reducing downtime and risk. Source: Stratus Technologies

Running all applications on a highly available and fault tolerant Edge Computing platform eliminates siloed islands of automation, saves on software licensing costs, and helps protect against expensive downtime without introducing added risk.

Resilience-by-Design in a world where downtime is not an option.

Stratus prides itself on offering Edge Computing platforms that are resilient-by-design. Solutions running on Stratus provide continuous availability and help prevent downtime in critical applications, such as those in industrial automation and control. They additionally benefit from ease of deployment and management as well as added protection.

Real-World examples of how OT modernization and optimization drive business outcomes

Edge Computing can benefit various verticals, including discrete, process, and hybrid manufacturing. This technology is beneficial to companies that generate substantial amounts of data daily and need actionable insights to optimize their operations and enhance business outcomes.

In the following four real-world examples, discover how companies have improved their operations with the adoption of Edge Computing.

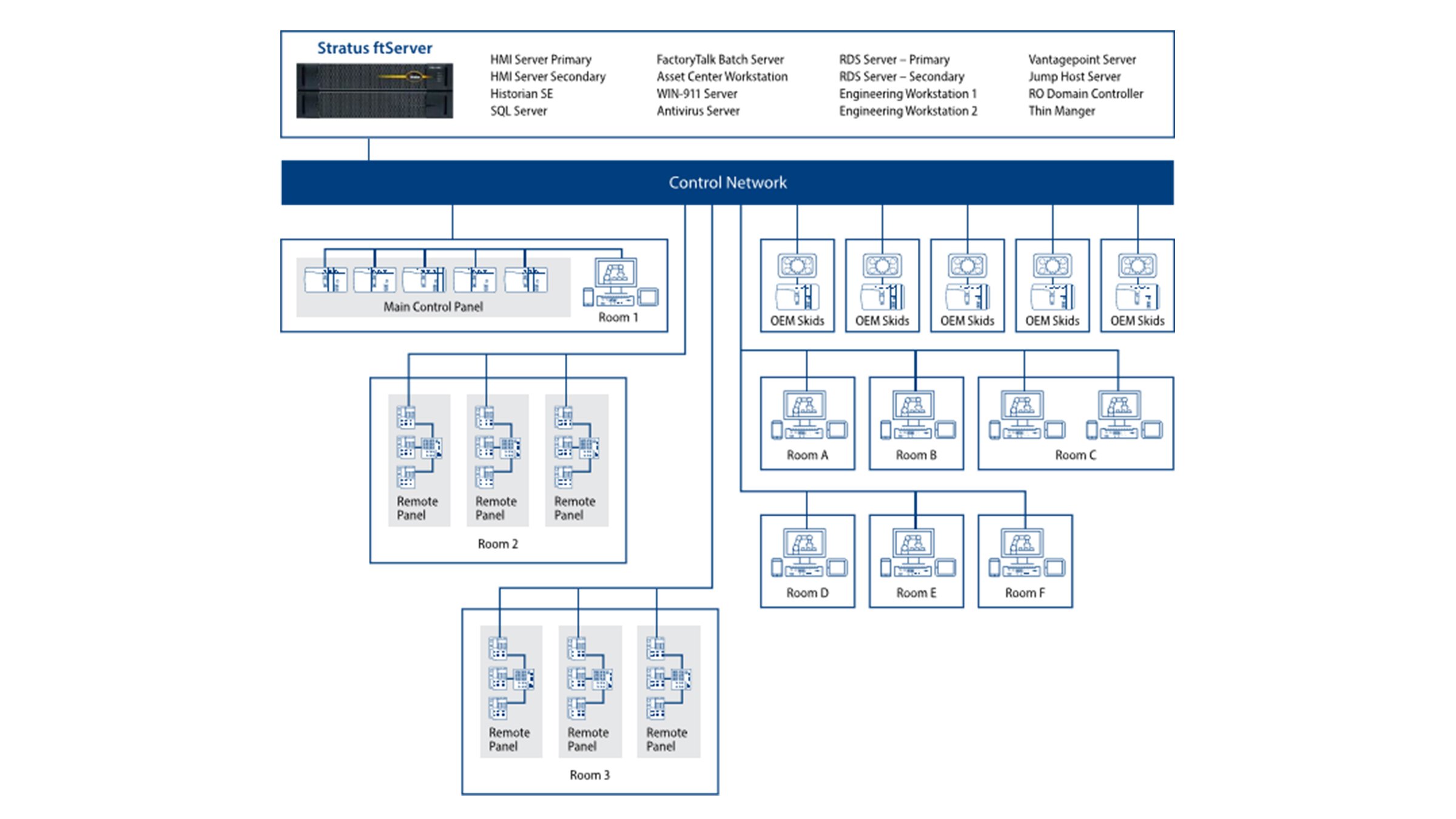

Eliminating disparate silos in Life Sciences

The life sciences industry requires reliable and efficient control architectures to deliver compliance with regulations and avoid costly downtime. Rovisys, a global system integrator specializing in automation, helped a large life sciences company upgrade its component manufacturing plant's control architecture.

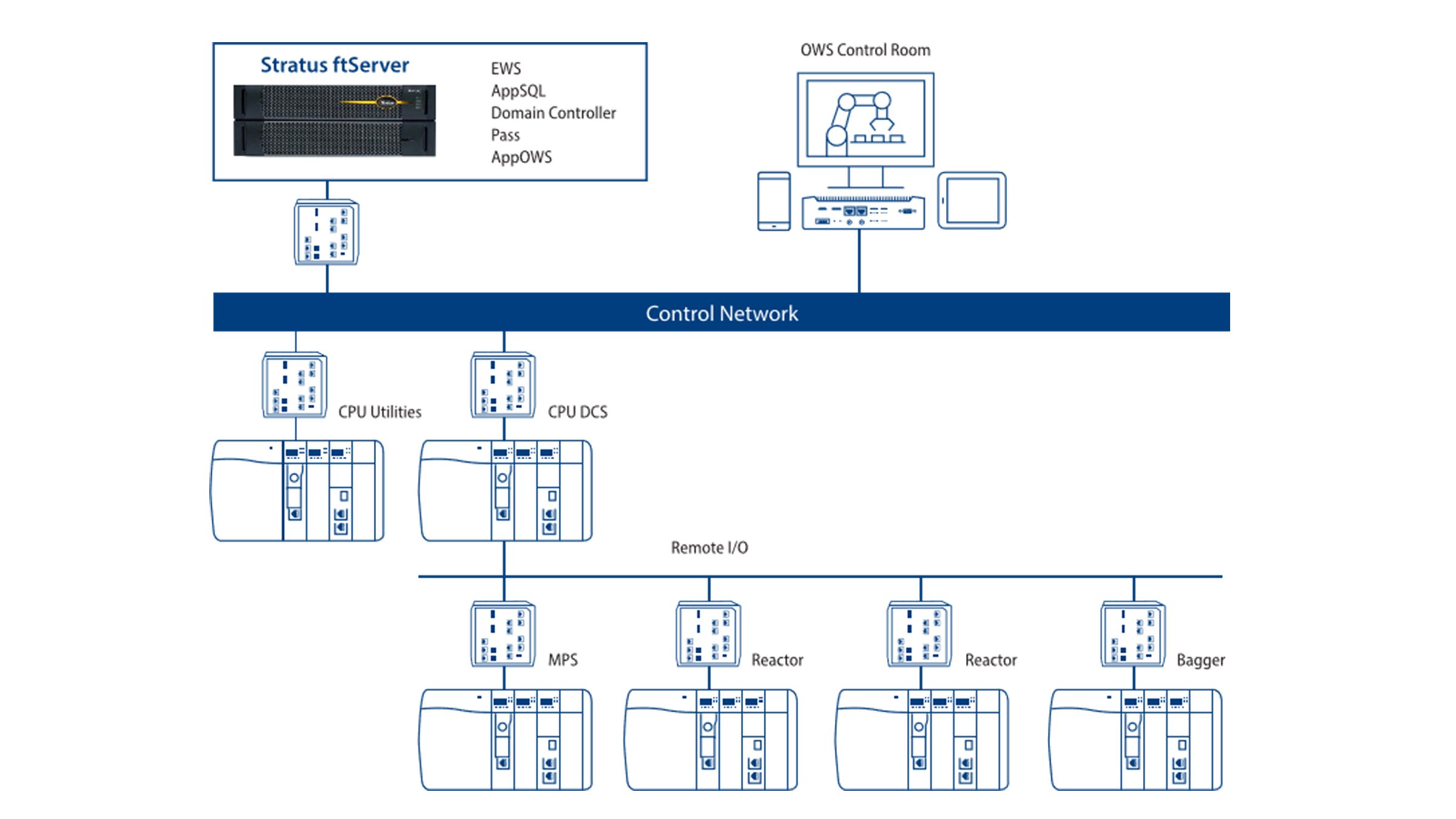

Figure 3: With workload consolidation the customer has all their software assets in one redundant Edge Computing platform. Source: Stratus Technologies

The plant had been relying on server clusters, resulting in unplanned downtime and data loss. To solve these issues, Rovisys consolidated the workload by upgrading to a platform that allows multiple software assets to be transferred to one redundant edge platform.

Stratus Edge Computing also simplifies Good Manufacturing Practice (GMP) validation and regulation compliance, resulting in an estimated 15-20% lower total cost of ownership (TCO) and an industry best 15-year lifespan.

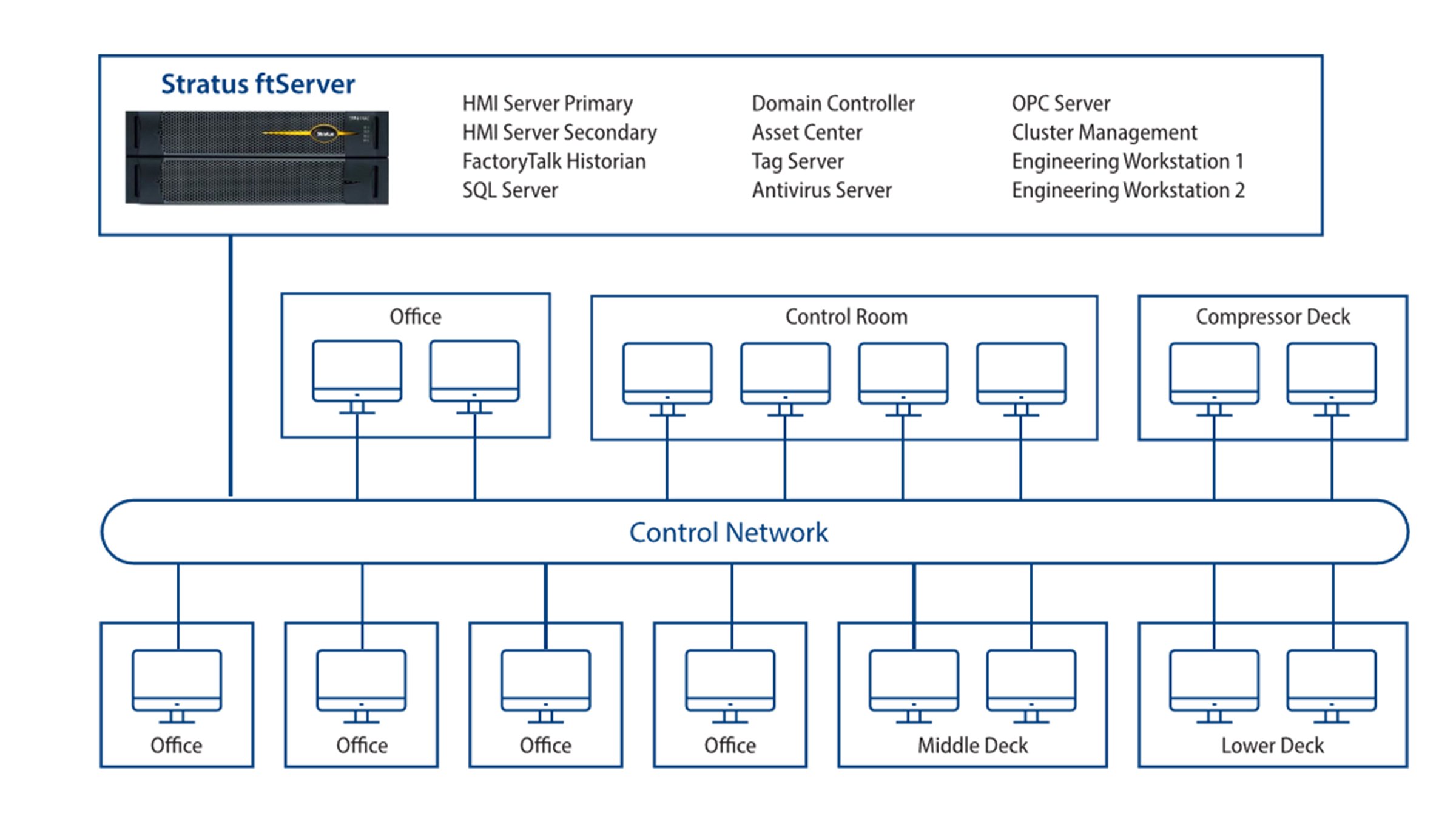

Resilience by Design in Oil and Gas

QuarterNorth Energy partnered with Enginuity Global to increase operational resilience at its Bullwinkle oil platform in the Gulf of Mexico. Enginuity replaced an aging control system with a Rockwell Automation PlantPAx® distributed control system (DCS) and consolidated 12 applications from six individual servers onto one fault-tolerant Stratus ftServer platform.

Figure 4: For mission-critical applications such as an Oil and Gas platform in the middle of the Gulf of Mexico, you need a platform that helps prevent unplanned downtime. Source: Stratus Technologies

This solution has resulted in higher yield, improved safety and cybersecurity, and the prevention of costly, unplanned downtime for the 1,736-ft.-tall offshore oil platform.

Improved scalability and flexibility in Chemicals

Chemical products manufacturer, Synthomer, has a production plant controlled by multiple PLCs from different manufacturers. These created islands of automation that were difficult and expensive to maintain and operate.

Figure 5: Synthomer modernized the plant’s disparate control system with a Stratus Edge Computing platform running Rockwell Automation PlantPAx® DCS, with the help of system integrator, Progetta. Source: Stratus Technologies

To solve this challenge, Synthomer replaced all existing multi-branded PLCs with Allen‑Bradley® ControlLogix® PACs. They also modernized the plant’s control system with a Rockwell Automation PlantPAx® DCS and a Stratus ftServer.

The new Edge Computing platform provided the scalability, flexibility, and extensibility to evolve and grow the plant’s systems as the needs and budgets grow, rather than a “rip and replace” approach.

Achieving standardization in Maritime

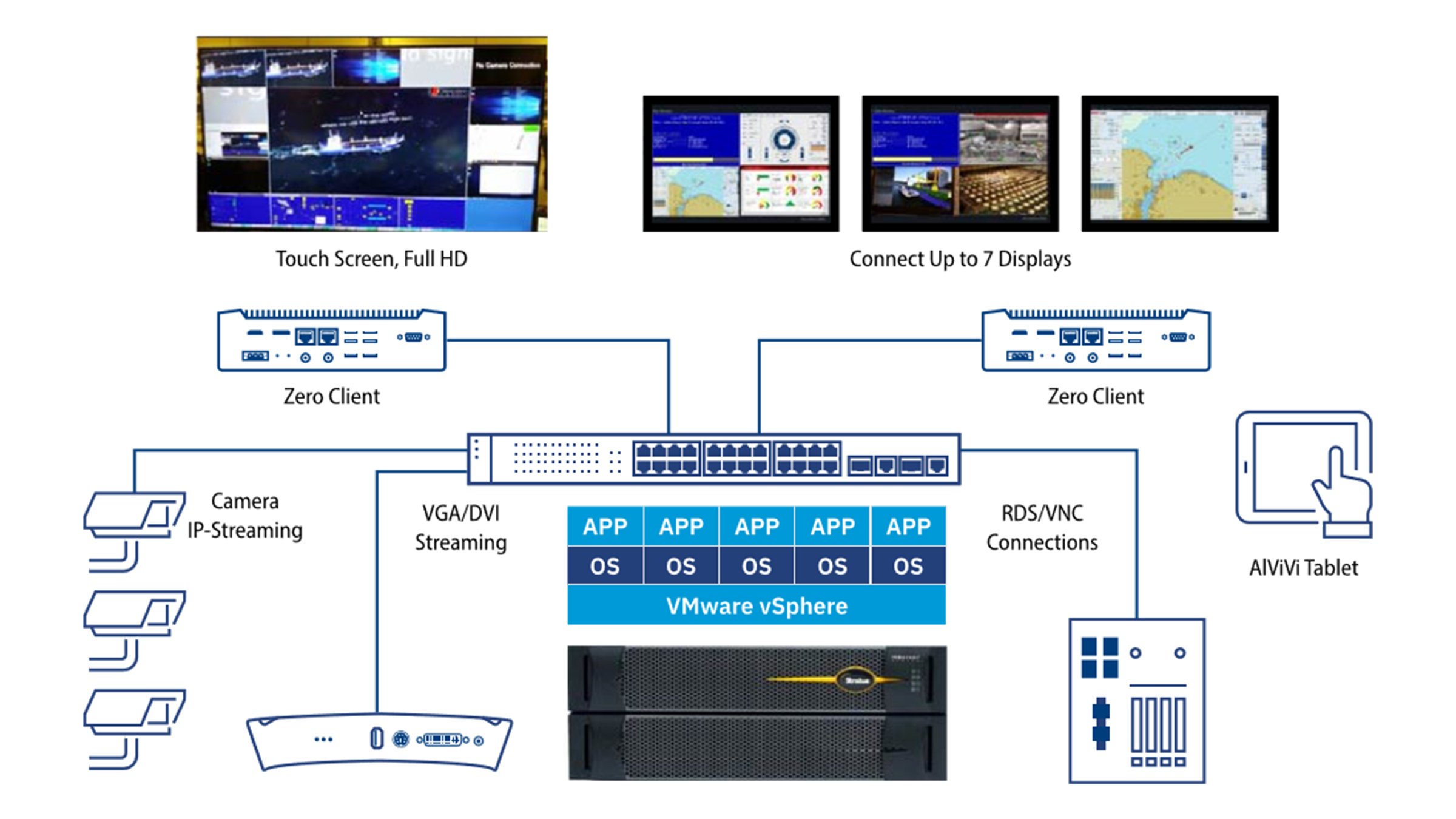

Netherlands-based Alewijnse is a leading provider of automation and control solutions for the maritime industry. The company has adopted a new Edge Computing platform that allows it to create and deploy its proprietary applications quickly and easily.

Figure 6: Netherlands-based Alewijnse is a global leader in maritime technology, providing critical systems for vessels ranging from yachts and naval ships to increasingly complex dredging, offshore, and transportation rigs. Source: Stratus Technologies

The resulting solution runs on Stratus ftServer, Rockwell Automation PLCs, and ThinManager®.

With the ability to create application images and easily deploy them into virtual machines, Alewijnse now has the capacity to replicate their customized solution for use in other vessels and for different customers.