Recommended For You

Challenge

- Amongst growing global competition in the automotive industry, 3V Automation needed to differentiate their machine offerings for their customers

Solutions

- Information Solutions - FactoryTalk® Innovation Suite, powered by PTC helped to accelerate 3V Automation’s digital transformation

- ThingWorx IIoT platform provided the capability to connect, manage, monitor, and control diverse automation devices and software applications through one intuitive user interface

- Augmented Reality - Vuforia delivered enhanced operations and remote maintenance capabilities through AR technology

Results

- Digital Transformation - 3V Automation has created a new ecosystem of connected machines and analytics to remotely support global customer workforces

- Improved Productivity and Customer Satisfaction - New solution has improved productivity, reduced downtime, and lowered maintenance costs and risks

- Improved return on investment to customers

- Collaboration with Rockwell Automation delivers an international solution to worldwide customers

Electric vehicles (EVs) are transforming the automotive industry. Bloomberg estimates that by 2040, 54 percent of new vehicle sales will be electric. And by 2030, it is predicted that 100 percent of passenger vehicles in China and India will be electric.

To meet this demand, automakers are calling for innovative solutions from tier 1 suppliers throughout their supply chain. There is room throughout the entire EV supply chain to integrate new technologies and improve productivity.

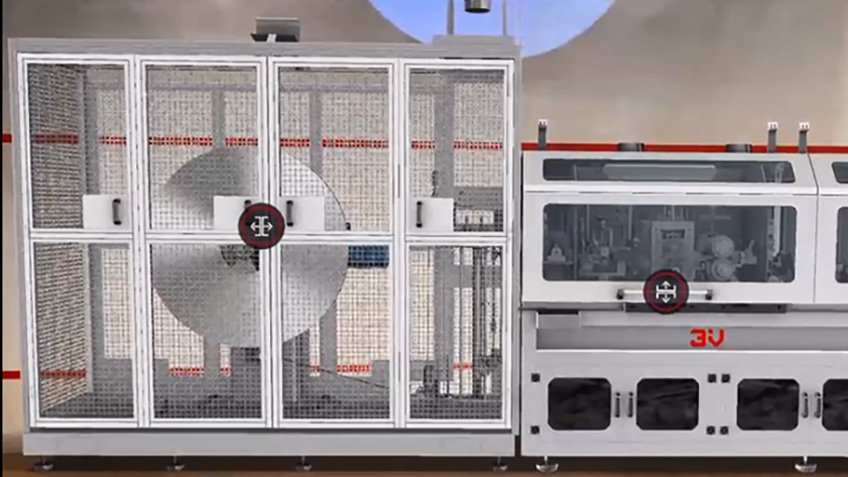

3V Automation is an intelligent automation company focusing on automated production and process engineering. The company was founded in 2013 in Tianjin China and has now grown to become a global market leader in the automotive and industrial heat exchange industries.

With a rapidly growing specialty in new energy process automation for the automotive industry, 3V Automation knew that digital transformation of their operations would help create new value and revenue streams.

Implementing tomorrow’s technology today

As a result of growing global competition in the automotive industry, 3V Automation recognized that their customers would benefit from a differentiated machine offering. To position automakers for greater success, 3V Automation worked with Rockwell Automation to implement the latest digital technologies for smart machines and equipment.

3V Automation needed to build smart machines to meet their customers’ requirements both today and into the future. Therefore, it was clear that 3V Automation would benefit from leveraging their existing platform and data to deliver more insights and value.

The enabling technologies that could make this possible included a new Industrial Internet of Things (IIoT) platform, scalable analytics as well as Augmented Reality (AR) for enhanced operations and remote maintenance.

Enabling Technologies for Digital Transformation

Digital transformation requires secure, reliable, seamless connectivity to all industrial assets. To continue to provide industry leading smart machines to tier 1 automotive customers, 3V Automation knew that by making their data more accessible productivity and visibility would be improved – ultimately enabling more informed business decisions.

The focus of the project was to leverage the existing plant floor data to bring more value with the new IoT platform, FactoryTalk InnovationSuite, powered by PTC.

As part of InnovationSuite, ThingWorx IIoT platform connects disparate devices, applications and data sources across the enterprise, providing a single source to collect, aggregate, and enable secure access to industrial operations data. It provides the capability to connect, manage, monitor, and control diverse automation devices and software applications through one intuitive user interface.

3V Automation also implemented the latest AR technologies to improve workforce productivity, efficiency and customer satisfaction. FactoryTalk Innovation Suite’s Vuforia provides the capability for machines to be assembled with AR technology. This helps to improve diagnostics through access to the machine’s real time data. It also provides detailed, xray analysis of key machine parts for customer demonstrations and training.

Expanding new capabilities

With the introduction of advanced IIoT technologies, 3V Automation has created a new ecosystem of connected machines and analytics to remotely support global customer workforces, while growing their digital service business model.

3V Automation’s domain expertise and progressive nature, together with the technology platform from Rockwell Automation will help them differentiate in the marketplace. It will help to deliver new revenue streams and return on investment to their customers.

By utilising information solutions, analytics and augmented reality, 3V Automation has been able to improve production, reduce downtime, and lower maintenance costs and risks.

In the near future, 3V Automation will be exploring more IIoT technology and machine learning so that they can continue to empower their customers’ operational productivity and intelligence. 3V Automation is creating a new future in the automotive industry – working together with Rockwell Automation to build an international solution to customers around the world.

Published December 11, 2019