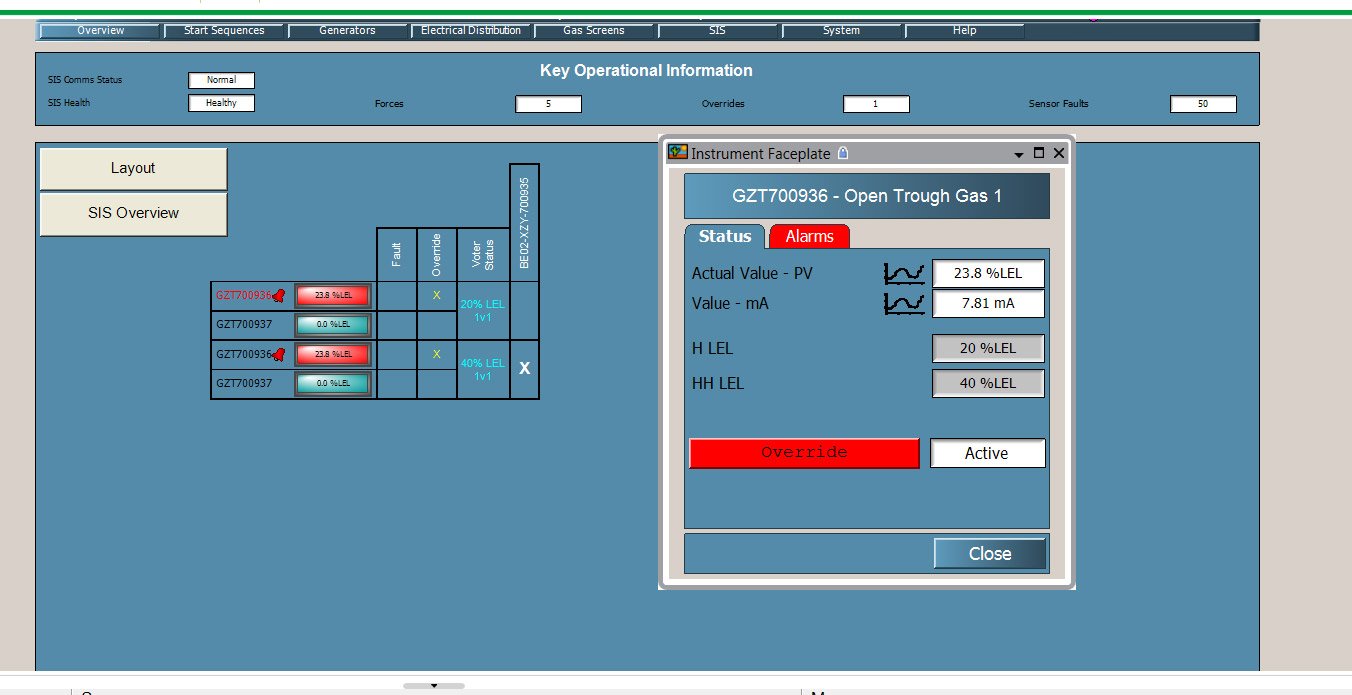

If there was a fire or gas event, the generators would need to have a quick and effective emergency shutdown procedure for safety. The AADvance system met this requirement by providing a fully independent shutdown path to the gas generator units, isolation of fuel gas valves and associated electrical systems. The system also immediately triggers the effected generators’ beacon and siren system plus the Plant Wide Emergency Siren giving personnel who may be in the area maximum time to evacuate.

To help make the commissioning process as seamless as possible, detailed FAT testing was conducted and was integrated with the existing plant HMI system. “When we were ready to commission the system onsite, we didn’t have to make any changes thanks to the prior testing. In addition, the control room only offered a confined amount of space but because the AADvance system was so compact we could fit it into a standard panel,” said Nigel Campbell, field technical lead, PSA Engineering.

Fire and gas safety compliance

As a result of the upgrade, the plant is now compliant with IEC 61511 SIL2 design Fire and Gas Safety Instrument System regulations. Furthermore, the system was designed to meet the strict guidelines of OLF, the Norwegian Oil Industry Association. OLF-070 sets a high safety performance target for fire and gas safety systems designed as per this standard.

Rockwell Automation has assisted PSA with comprehensive system training and support for the duration of the project. This collaboration has allowed for the sharing of lessons learned and best practices used on a global scale, which helps to deliver effective solutions to the oil and gas market.

“As part of our Recognized System Integrator Program with a specific focus on process safety, Rockwell Automation enjoys a longstanding relationship with PSA. We support PSA through our global network of technical support for our process solutions. This support helps to enable execution for defined project deliverables in the oil and gas industry,” said Wayne Perry, sales manager Queensland, Rockwell Automation.

About Rockwell Automation

Rockwell Automation Australia and Rockwell Automation New Zealand are subsidiaries of Rockwell Automation, Inc.—a leading global provider of industrial automation and information solutions that helps manufacturers achieve a competitive advantage in their businesses. The company brings together leading global brands in industrial automation which include Allen-Bradley® controls and services and Rockwell Software® factory management software. Its broad product mix includes control logic systems, sensors, human-machine interfaces, drive controllers, power devices, and software.

Rockwell Automation Inc. (NYSE: ROK), is a global leader in industrial automation and digital transformation. We connect the imaginations of people with the potential of technology to expand what is humanly possible, making the world more productive and more sustainable. Headquartered in Milwaukee, Wisconsin, Rockwell Automation employs approximately 23,000 problem solvers dedicated to our customers in more than 100 countries. To learn more about how we are bringing The Connected Enterprise® to life across industrial enterprises, visit www.rockwellautomation.com

AADvance, Allen-Bradley, PartnerNetwork, Rockwell Automation and Rockwell Software are trademarks of Rockwell Automation, Inc.

Media contact:

Christine Filippis

Teraze Communications

61 3 8391 0701

christine@teraze.com.au