Rockwell Automation, the world’s largest company dedicated to industrial automation and digital transformation, has announced the iTRAK® 5750 Intelligent Track System, providing companies the opportunity to redefine machine productivity using faster, smarter and more flexible motion.

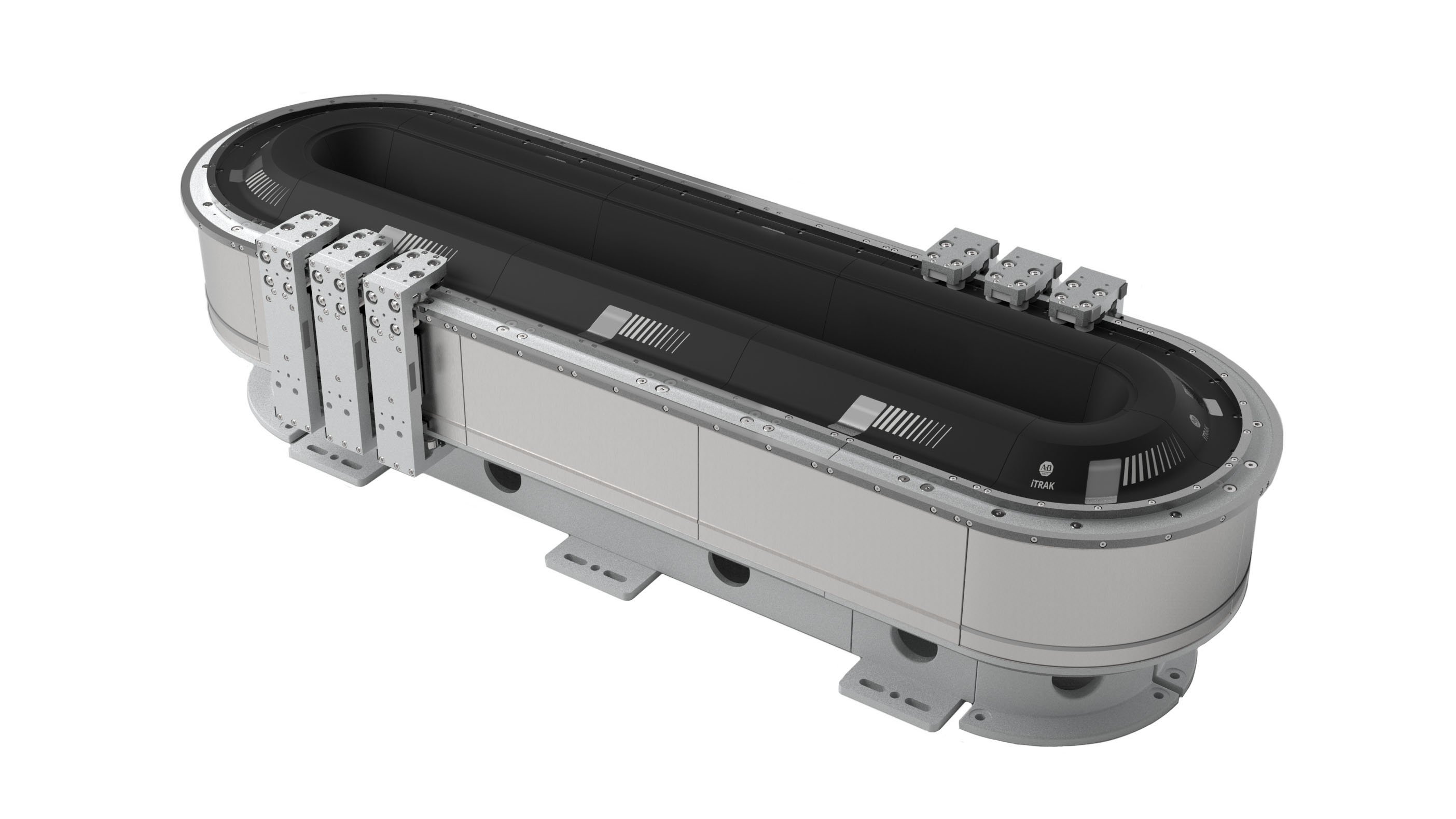

The system expands the Rockwell Automation iTRAK portfolio with a specialized design that is optimized for heavier payload applications. It replaces the mechanical components and complex linkages of traditional conveyor systems, instead using electromagnetic force to generate motion.

This revolutionary way to move goods provides an opportunity to design more reliable machines that require less maintenance and deliver new levels of productivity. The versatile system comprises of a variety of straight and curved tracks, offering the ability to tailor each system to its exact application requirements.

The iTRAK 5750 Intelligent Track System enables companies to keep up with technology that allows independent movement of each individual carrier and simple control of motion through user-friendly software profiles. This can remove bottlenecks and boost overall productivity so that short runs can become more profitable, while margins can be expanded in standard runs. Seamless integration with complete Allen‑Bradley solutions provides optimized communication and synchronization with surrounding devices, such as robots.

With the capability to add exceptional speed, intelligence and flexibility to a wide variety of motion processes, the iTRAK 5750 Intelligent Track System helps transform the performance of automation systems and usher in a smarter manufacturing future.