In life sciences and the wider automation industry, modular equipment concepts have gained favor in recent years. Although the trend benefits production equipment commissioning, it adds complexity to qualifying a plantwide automation system.

For life sciences manufacturers, horizontal integration (machine-to-machine automation) and vertical integration (machine-to-plant automation) are often the last steps before production. These steps include qualifying programmable logic controller (PLC) code operation on packaged equipment — such as a skid — and commissioning the distributed control system (DCS) responsible for plantwide automation. Plant automation engineers often work in the DCS with function block diagram objects while equipment specialists work with ladder logic in the PLC.

As the interest in modularity grew, so did a potential challenge for manufacturers: one company providing the plantwide distributed control system (DCS), a different company supplying automation components for the production equipment, and even multiple third-party components on other pieces of equipment. As a result, the number of programmable logic controllers (PLCs) entering the plant multiplied.

As some groups working in life sciences realized the benefits of ordering a skid out of a catalog vs. building the unit operation on site, the end-user organizations responsible for integrating the products grew more frustrated. Eventually, automation engineers demanded that their automation components have plug-and-produce capabilities, the same as the production equipment.

Member organizations and companies within the industry, including Rockwell Automation, have responded to that call. Their efforts have sought to stabilize and solidify the foundation for plug-and-produce technology.

The drive for modularity

One of the groups advancing plug-and-produce technology is NAMUR, the User Association of Automation Technology in Process Industries. This international group based in Germany represents users of automation technology, including process control technology specialists.

With more than 150 member companies across the globe, NAMUR and its members know the value of plug-and-produce modules — specifically, making it easier to replace skids of a specific function with another. They also understand how plant operators want to work: standard interfaces with standard data.

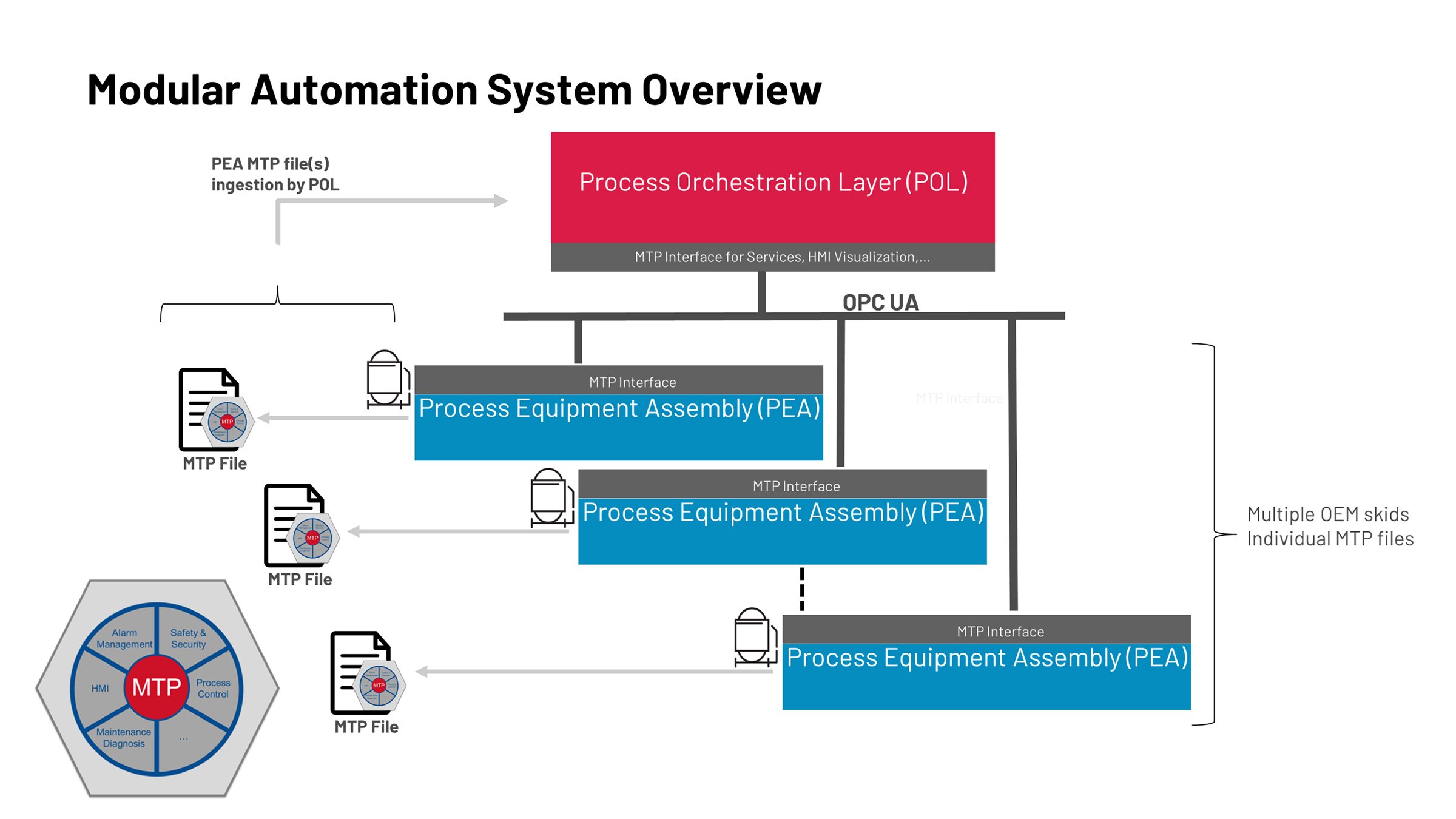

The group is helping create a modular-specific standard called modular type package (MTP) (VDI/VDE/NAMUR 2658) that includes various sections covering everything from data aspects to human-machine interfaces (HMI). The standard describes functionality — such as comms, alarms, safety, and so on — using the OPC Unified Architecture (UA).

The MTP standard is written to be compatible with other NAMUR recommendations: NE148 and the Reference Architecture Model for Industry (RAMI) 4.0. MTP has advanced to an IEC standard about the lifecycle of components in a facility. It basically says everything should be modularized so it is easy to upgrade or replace a piece at any time. We’ll explore its function after getting familiar with some key terms from VDI 2776 Part 1:

- Process equipment assembly (PEA) — an automated and, from a safety perspective, almost autonomous modular process unit, which consists of one or more functional equipment assemblies and represents a processing step or provides infrastructure within a modular plant

- Process orchestration layer (POL) — an equipment assembly spanning automation and information technology level for the operation of modular systems

- MTP — a formal description of the interfaces and functions of the automation technology of a modular process unit