Recommended For You

Solutions

- PACs - Allen-Bradley ControlLogix programmable automation controllers to manage the rate of water flowing through the turbines, while monitoring critical river elevations behind the dam

- HMI - FactoryTalk View SE stations for valuable diagnostics and monitoring via EtherNet/IP

- Manufacturing Intelligence - FactoryTalk AssetCentre software to track users’ actions, manages asset configuration fi les, configure process instruments and provide backup/recovery

- PlantPAx Process Automation System - FactoryTalk Historian SE collects time-series data used for various calculations, estimations and quality controls throughout the enterprise

Results

- Plant efficiency optimized by automated monitoring and control of the turbine and generator systems

- More accurate, real-time data collected automatically and shared electronically among departments, improving analysis and forecasts, and eliminating need for error prone printouts

- Troubleshooting simplified because operators can detect and correct problems earlier

- Remote monitoring capabilities predicted to reduce manpower and travel costs

Background

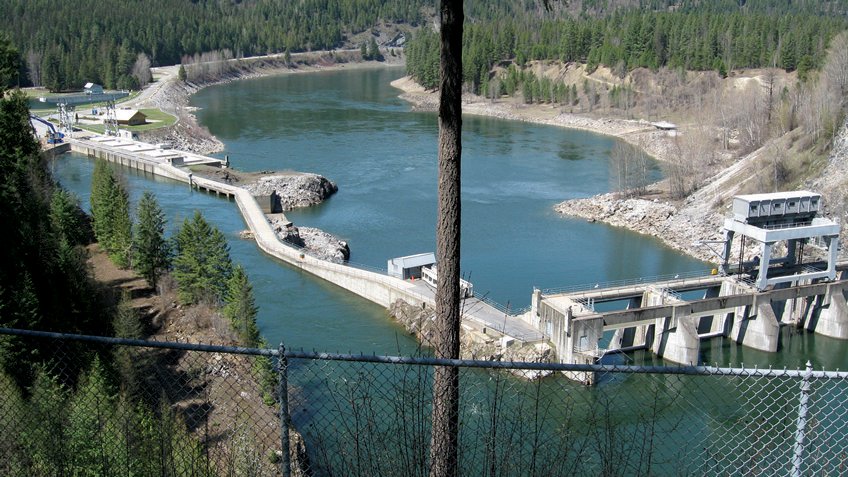

Box Canyon Dam was turning river current into electrical current long before “renewable energy” became an environmental gold standard. Since 1956, Box Canyon Dam and its four hydroelectric generators have straddled a narrow section of Washington state's second-largest river, the Pend Oreille (Pond-er-ray).

The Pend Oreille County Public Utility District built and operates the 80-megawatt-capacity hydro plant, which today provides renewable energy to 8,500 customers. Box Canyon is a run-of-the-river hydro plant, meaning the flow of water from upstream sources drives the submerged turbines.

By contrast, most major hydroelectric plants generate electricity by systematically controlling the release of stored water behind a dam.

Still, control is critical at Box Canyon to maintain the delicate balance between optimal power generation and the river's natural ecosystem.

Seasonal rains, melting snowpack and other natural forces put pressure on Box Canyon, swelling the incoming flow from upstream dams and reservoirs. Swift currents are a plus for hydro power production because they efficiently turn the turbines, which then spin electromagnets to generate energy.

But state-protected lands behind Box Canyon can't be allowed to flood. That's because they're home to sensitive animal habitat and picturesque public parks that attract thousands of visitors annually to Washington's northeast corner.

So Box Canyon operators work continuously to control the amount of water flowing through the dam and the elevation of the river behind it.

Challenge

This operational and environmental equilibrium has been achieved largely by hand at Box Canyon Dam. That's because most of the original mechanical controls and hydroelectric equipment – including the four turbines, generators and auxiliary machinery – remained in use more than 50 years after they were installed.

“Even for a team of highly experienced operators, that's a lot of working parts to monitor and adjust separately,” said Terry Borden, manager of hydro production at Box Canyon. “We also have to contend with whatever the weather throws at us.”

While the average flow rate at Box Canyon is 26,400 cubic feet per second (cfs), for instance, spring thaws and early summer rains can push that level to 80,000 cfs and above. At those rare heights, operators stop the turbines and open the dam's hydraulic gates to let the rushing river flow unfettered through spillways.

Day-to-day fluctuations in the river are far less dramatic, but still can vary significantly. To contend with those variations, operators consistently monitor flow rates and water elevations behind the dam. They use that information to control the flow through the dam by adjusting the turbines' wicket gates – large doors that open to allow water into the turbines. The goal is to keep power production as close to peak as possible while keeping river levels as stable as possible.

Collecting the critical data involved in the power generation process also has been a largely manual process, with operators recording instrument readings by hand. Without an electronic network to share the data, operators had to enter it into Excel spreadsheets and then distribute hard copies to other departments. Purchasing employees, for example, use month-to-month trending data to help calculate power contracts.

“All our systems were out of date,” Borden said. “And because no real upgrade of the control station and the equipment had been done since the plant was built, everything was just worn out.”

The Federal Energy Regulatory Commission (FERC) recently noted the need for modernization when Box Canyon applied to renew its license for the next half century. FERC granted the license but stipulated the plant had to invest in upgrades to comply with the latest federal standards.

“We needed state-of-the art automation to meet all our requirements, from integrated control to real-time reporting to plant security,” Borden said.

Solutions

Before the project began, Borden and his team knew they wanted Rockwell Automation to provide the comprehensive control solution the plant needed.

“We had invested in four Allen-Bradley® SLC controllers, one on each turbine's governor blade control system, so we had some experience with Rockwell Automation,®” Borden said. “Just from being in the power industry, we also knew about the innovations Rockwell Automation has developed to meet the unique requirements of hydroelectric generation.”

The Pend Oreille utility district selected the PlantPAx process automation system, an integrated control and information solution that combines capabilities of a distributed control system with pervasive access to process information to help achieve plant-wide optimization. This scalable, multi-disciplined platform helps users who need both process and sequential control to achieve lower total cost of ownership and a plant-wide view.

Implementation of the PlantPAx solution at Box Canyon is happening in stages, along with the rest of the $150 million project. That's because the district must continue to produce power during the upgrade, using three of the four turbine/generator units at all times. One unit has already been replaced and the second is under way. The process includes totally disassembling the unit down to its concrete foundation. Then the new turbine and generator are installed, along with new switch gear, relay-protection systems, pumps and pipes.

The PlantPAx solution includes two Allen-Bradley ControlLogix® programmable automation controllers (PACs) for each unit – one to control the turbine governor system and the other for general unit controls, auxiliary pumps and stopping and starting the generators. In the control room, a series of FactoryTalk® View Supervisory Edition human-machine interface stations provide operators with valuable information and diagnostics via EtherNet/IP.™ FactoryTalk SE Server software consolidates human-machine interface data from the hydro units, allowing Box Canyon operators to centrally monitor and manage system parameters, such as river elevations and flow rates. FactoryTalk Historian SE provides for centralized data, event and alarm databases.

“The PlantPAx system architecture also opens up communication between the PACs and third-party equipment through EtherNet/IP, so valuable information is instantly available to everybody who needs it,” Borden said.

Results

The new system has helped increase generating efficiency at the plant by allowing more exact monitoring of the turbine and generator systems. In turn, operators can detect and correct problems earlier, such as high temperatures in the generator or low flow in cooling systems.

“It's too soon to put a number on it, but we anticipate this increased reliability and unit uptime will reduce operating costs once the entire project is complete,” Borden said. “Also, operators will be able to perform additional maintenance tasks they don't have time for now, like digging trash out of the intakes.”

Box Canyon Dam already is reaping the benefits of automated data collection through the PlantPAx system.

“Working seamlessly together, the ContolLogix controller and FactoryTalk software have allowed us to capture more real-time information, and retain it for future analysis and trending,” Borden said. “System data is also automatically sent to a corporate network database that allows other departments to easily access the information, rather than shuffle through print-outs.”

The security features offered by the FactoryTalk AssetCentre software also enable the direct reporting and documentation required under the North American Electric Reliability Corporation's critical infrastructure protection provisions (NERC CIP).

Once the turbine/generator project is completed, Borden and his team plan to take full advantage of the remote monitoring capabilities offered by the new process control system. The utility district operates a smaller dam and pumping stations outside Box Canyon, and it plans to improve their connection to the district's supervisory control and data acquisition (SCADA) system.

“Our new process capabilities will allow the district to monitor and operate remote sites from one central location, saving on both labor and travel costs,” Borden said. Also on the utility's agenda is the incorporation of a fishpassage system at the dam. This will protect bull trout and other species on their downstream and upstream journeys.

“This is a fairly large project that will require automated control. More than likely, we'll use Rockwell Automation for that,” Borden said. “The quality of the products and the tremendous support – both locally and from their Milwaukee headquarters – have sold us on Rockwell Automation.”

Published April 1, 2012