How Can My Infrastructure Help Improve Asset and System Performance?

Your goals may also require the implementation of new capabilities that are related to system or asset-performance management.

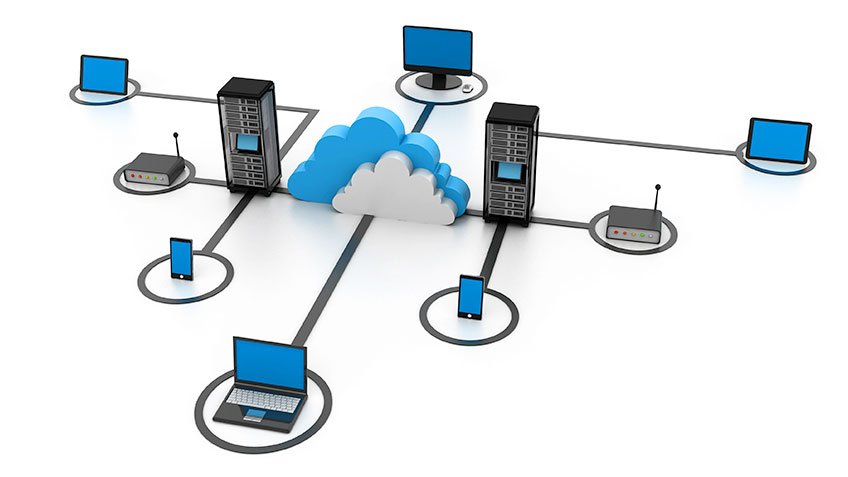

With a secure and robust information infrastructure, you now have the connectivity that is required to tap into strategies that can boost your bottom line. Large amounts of data lives within your production assets, but it needs to be transformed into useful information to drive performance improvements.

Asset Reliability services combine a mix of industry expertise and electrical automaton controls knowledge with continuous improvement processes, reliability techniques, and asset intelligence systems to help drive plant productivity, improve asset reliability over your equipment lifecycle, and streamline maintenance activities.

Preventive Maintenance service agreements can keep your critical assets running at peak efficiency. From identifying pending system failures to recommending which components should be repaired or replaced, these services can help mitigate the unnecessary repairs and associated costs that occur with most time-based preventative maintenance programs.

Remote Monitoring services can reduce Mean Time To Repair (MTTR) by 76 percent and reduce the cost of managing your infrastructure.

Analytics services can help you predict machine failures, reduce Mean to Between Failure (MTBF), and automate maintenance activities to reduce downtime by up to 30 percent.

Such services also have value beyond day-to-day process improvements and issue resolutions. You can use access to insights to optimize your larger operations and transform how you do business, reduce downtime recovery, help integrate your supply chain, design material orders to automatically replenish after a certain number is met, or even build customized dashboards to view production data and asset or system health that is most important to your specific needs.